- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄1899 > ADMC401BSTZ (Analog Devices Inc)IC DSP 8CH 12BIT MOTCTRL 144LQFP PDF資料下載

參數(shù)資料

| 型號(hào): | ADMC401BSTZ |

| 廠商: | Analog Devices Inc |

| 文件頁(yè)數(shù): | 16/60頁(yè) |

| 文件大?。?/td> | 0K |

| 描述: | IC DSP 8CH 12BIT MOTCTRL 144LQFP |

| 標(biāo)準(zhǔn)包裝: | 1 |

| 系列: | 電機(jī)控制 |

| 類型: | 定點(diǎn) |

| 接口: | 串行端口 |

| 時(shí)鐘速率: | 26MHz |

| 非易失內(nèi)存: | ROM(6 kB) |

| 芯片上RAM: | 8kB |

| 電壓 - 輸入/輸出: | 5.00V |

| 電壓 - 核心: | 5.00V |

| 工作溫度: | -40°C ~ 85°C |

| 安裝類型: | 表面貼裝 |

| 封裝/外殼: | 144-LQFP |

| 供應(yīng)商設(shè)備封裝: | 144-LQFP(20x20) |

| 包裝: | 托盤(pán) |

第1頁(yè)第2頁(yè)第3頁(yè)第4頁(yè)第5頁(yè)第6頁(yè)第7頁(yè)第8頁(yè)第9頁(yè)第10頁(yè)第11頁(yè)第12頁(yè)第13頁(yè)第14頁(yè)第15頁(yè)當(dāng)前第16頁(yè)第17頁(yè)第18頁(yè)第19頁(yè)第20頁(yè)第21頁(yè)第22頁(yè)第23頁(yè)第24頁(yè)第25頁(yè)第26頁(yè)第27頁(yè)第28頁(yè)第29頁(yè)第30頁(yè)第31頁(yè)第32頁(yè)第33頁(yè)第34頁(yè)第35頁(yè)第36頁(yè)第37頁(yè)第38頁(yè)第39頁(yè)第40頁(yè)第41頁(yè)第42頁(yè)第43頁(yè)第44頁(yè)第45頁(yè)第46頁(yè)第47頁(yè)第48頁(yè)第49頁(yè)第50頁(yè)第51頁(yè)第52頁(yè)第53頁(yè)第54頁(yè)第55頁(yè)第56頁(yè)第57頁(yè)第58頁(yè)第59頁(yè)第60頁(yè)

ADMC401

–23–

REV. B

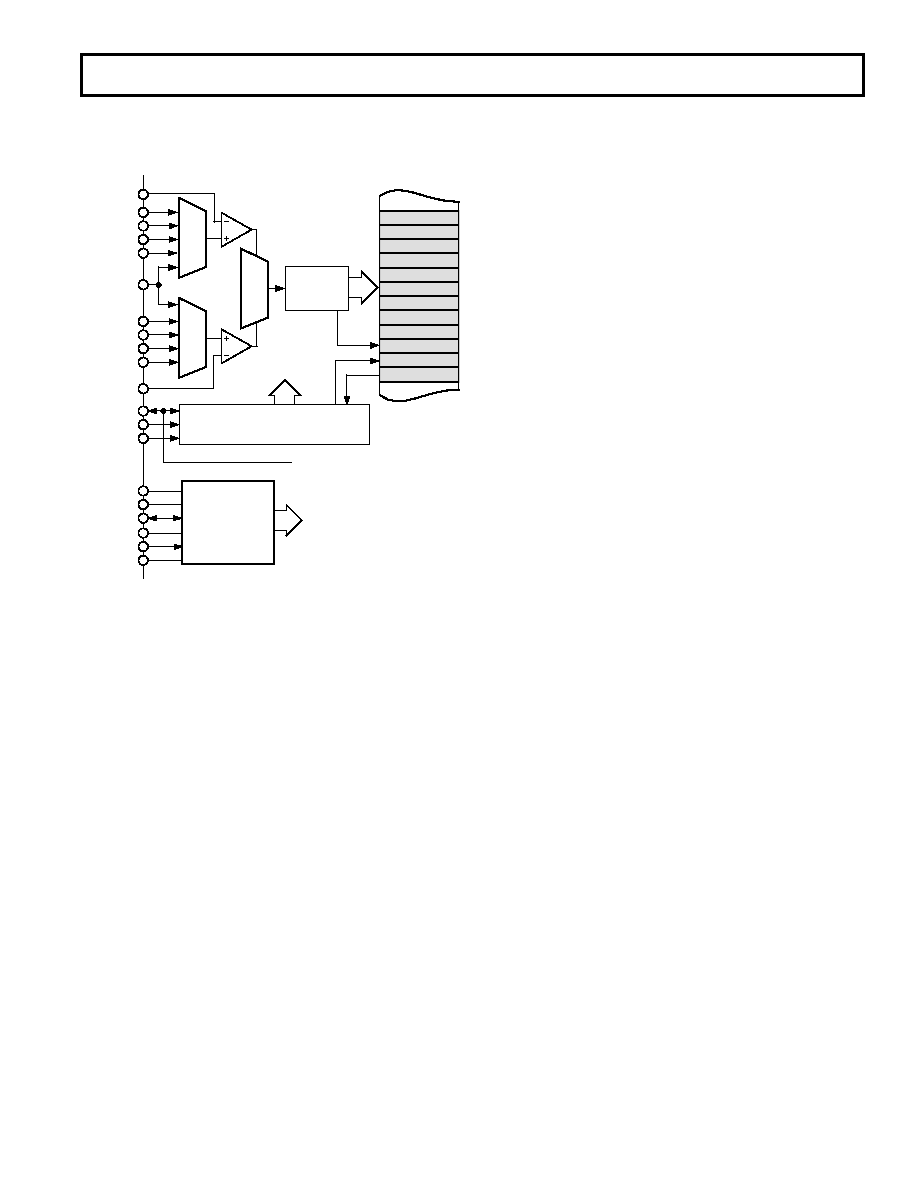

and BSHAN) to the inverting terminal of the two sample and

hold amplifiers (SHA) so that external signals can be correctly

biased about the nominal operating range of the ADC.

ADC0(15...0)

ADC1(15...0)

ADC2(15...0)

ADC3(15...0)

ADC4(15...0)

ADC5(15...0)

ADC6(15...0)

ADC7(15...0)

ADCOTR(7...0)

ADCSTAT(4...0)

ADCCTRL(4...0)

MULTIPLEXER, SHA AND ADC CONTROL

INTERNAL

REFERENCE

SIGNALS

ASHAN

VIN0

VIN1

VIN2

VIN3

VIN4

VIN5

VIN7

BSHAN

PWMSYNC

CONVST

CLKOUT

CAPT

CAPB

VREF

REFCOM

SENSE

CML

VIN6

VOLTAGE

REFERENCE

GENERATION

& CONTROL

12-BIT

PIPELINE

FLASH ADC

DATA

CONTROL SIGNALS

END OF

CONVERSION

OUT

OF

RANGE

MUX

SHA A

ADCXTRA(15...0)

GAIN

SHA B

PWMSYNC (FROM PWM PERIPHERAL)

Figure 16. Functional Block Diagram of the ADC System

of the ADMC401

The basic architecture of the ADC system consists of a four-

stage pipeline architecture (the A/D core) with wideband input

sample and hold amplifiers. Excluding the last stage, each stage

of the pipeline consists of a low resolution flash A/D connected

to a switched capacitor DAC and interstage residue amplifier

(MDAC). The reside amplifier amplifies the difference between

the reconstructed DAC output and the flash input for the next

stage in the pipeline. The last stage of the pipeline simply con-

sists of a flash A/D. The pipeline architecture allows a greater

throughput rate at the expense of pipeline delay or latency. This

means that while the converter is capable of capturing a new

input sample every ADC clock cycle, it actually takes 3 1/2 ADC

clock cycles for the conversion process of any input to be fully

processed and appear at the output.

The ADC may operate in two basic conversion modes, Simulta-

neous Sampling or Sequential Sampling. The operating mode is

selected by dedicated bits in the ADCCTRL register. In the

Simultaneous Sampling mode, two analog inputs (one from each

bank) are sampled simultaneously so that VIN0 and VIN4,

VIN1 and VIN5, VIN2 and VIN6, VIN3 and VIN7 represent

four pairs of simultaneously sampled inputs. In the alternative

sequential operating mode, there is no simultaneous sampling,

and the analog inputs are sampled and converted one after the

other (i.e., VIN0 followed by VIN1 followed by VIN2, etc.). In

this mode, successive analog inputs are sampled an ADC clock

period (or four DSP clock cycles) apart.

The conversion sequence may be initiated either internally (syn-

chronized to the PWM generation) or from an external event on

the CONVST pin. In the default Simultaneous Sampling mode of

operation, the internal control logic simultaneously samples the

first pair of input signals (VIN0 and VIN4) following the con-

vert start command. Subsequently, these inputs are multiplexed

into the 12-bit analog-to-digital converter. After a delay of two

ADC clock cycles, the second pair of analog inputs (VIN1 and

VIN5) are sampled simultaneously and then multiplexed into

the ADC. This process continues until all four pairs of analog

inputs have been sampled and converted. As the conversion for

a given analog input channel is completed, the corresponding

digital number is written to a dedicated 16-bit, twos comple-

ment, left-aligned register that is memory mapped to the data

memory space of the DSP core. The ADC data register ADC0

stores the conversion result for the signal on VIN0, etc.

Following the end of conversion of each pair of analog inputs, a

dedicated bit is set in the ADCSTAT register. The result of this

highly efficient pipelined structure is that all eight ADC data

registers will contain valid conversion results less than 2

s (at

26 MHz) after the convert start command. At this point a dedi-

cated ADC interrupt will be generated. Alternatively, if data is

required sooner, the ADCSTAT register can be polled to detect

when a given pair of analog inputs have been successfully con-

verted, except in Sequential Sampling mode.

Once the conversion sequence has been completed and all eight

ADC data registers have been updated, the entire ADC structure

automatically reverts to the Single Channel mode and continu-

ously converts the analog input on the VIN0 pin. The results of

this conversion are placed in the additional ADCXTRA register

and are updated once every ADC clock cycle. This feature could

be used to continuously monitor a single analog input on the

VIN0 pin.

There are two additional modes of operation of the ADC system

that may be used for offset and gain calibration of the entire

system. In the Offset Calibration mode, all analog inputs (VIN0

to VIN7, GAIN, ASHAN and BSHAN) are disconnected from

the inputs to the sample and hold amplifiers. Instead, both

terminals of each sample and hold amplifiers are connected

together and to the voltage reference. Following a conversion

sequence, the data in the ADC data register can be taken as a

measure of any offset in the sample and hold amplifiers and

ADC. Additionally, in the Gain Calibration mode, the dedicated

analog input GAIN is applied to the noninverting terminal of

both sample and hold amplifiers. Any number of precise exter-

nal voltages can be applied to this pin to measure and correct

for any gain errors, if required.

Along with each data output from the A/D converter, an Out-of-

Range (OTR) bit is set if the signal exceeds the permissible

input voltage span. In normal conversion, the eight OTR bits for

the eight analog inputs are stored in the ADCOTR register, with

one bit for each analog input. The OTR bit for the ADCXTRA

register is stored in the ADCSTAT register.

The ADC may use either an internally generated 2.0 V precision

reference voltage or an externally supplied reference voltage

level at the VREF pin. The operating mode is selected by the

connection of the SENSE pin.

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| ADN2850BCPZ25-RL7 | IC DGTL RHEO DL 25K 9BIT16LFCSP |

| ADN2860ACPZ250-RL7 | IC POT DGTL 3CH 250K 24-LFCSP |

| ADN4600ACPZ | IC CROSSPOINT SWITCH 8X8 64LFCSP |

| ADN4604ASVZ-RL | IC CROSSPOINT SWIT 16X16 100TQFP |

| ADN4605ABPZ | IC CROSSPOINT SWITCH 352BGA |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| ADMC401BSTZKL1 | 制造商:Analog Devices 功能描述: |

| ADMC401-PB | 制造商:AD 制造商全稱:Analog Devices 功能描述:Single-Chip, DSP-Based High Performance Motor Controller |

| ADMCF326 | 制造商:AD 制造商全稱:Analog Devices 功能描述:28-Lead Flash Memory DSP Motor Controller |

| ADMCF326BN | 制造商:Analog Devices 功能描述: |

| ADMCF326BR | 制造商:AD 制造商全稱:Analog Devices 功能描述:28-Lead Flash Memory DSP Motor Controller |

發(fā)布緊急采購(gòu),3分鐘左右您將得到回復(fù)。