- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄370425 > HAL805UT-E (MICRONAS SEMICONDUCTOR HOLDING AG) Programmable Linear Hall Effect Sensor PDF資料下載

參數(shù)資料

| 型號(hào): | HAL805UT-E |

| 廠商: | MICRONAS SEMICONDUCTOR HOLDING AG |

| 元件分類: | 磁阻傳感器 |

| 英文描述: | Programmable Linear Hall Effect Sensor |

| 中文描述: | MAGNETIC FIELD SENSOR-HALL EFFECT, -1-1mT, 0.35-4.65V, RECTANGULAR, THROUGH HOLE MOUNT |

| 封裝: | PLASTIC, TO-92UT, 3 PIN |

| 文件頁數(shù): | 10/24頁 |

| 文件大?。?/td> | 373K |

| 代理商: | HAL805UT-E |

HAL805

PRELIMINARY DATA SHEET

10

Micronas

Step 2: Calculation of V

OQ

and Sensitivity

The calibration points 1 and 2 can be set inside the

specified range. The corresponding values for V

OUT1

and V

OUT2

result from the application requirements.

For highest accuracy of the sensor, calibration points

near the minimum and maximum input signal are rec-

ommended. The difference of the output voltage

between calibration point 1 and calibration point 2

should be more than 3.5 V.

Set the system to calibration point 1 and read the reg-

ister ADC-READOUT. The result is the value ADC-

READOUT1.

Now, set the system to calibration point 2, read the

register ADC-READOUT again, and get the value

ADC-READOUT2.

With these values and the target values V

OUT1

and

V

OUT2

, for the calibration points 1 and 2, respectively,

the values for Sensitivity and V

OQ

are calculated as:

This calculation has to be done individually for each

sensor.

Next, write the calculated values for Sensitivity and

V

OQ

into the IC for adjusting the sensor.

The sensor is now calibrated for the customer applica-

tion. However, the programming can be changed again

and again if necessary.

Step 3: Locking the Sensor

The last step is activating the LOCK function with the

“

LOCK

”

command. The sensor is now locked and does

not respond to any programming or reading com-

mands.

Warning: This register cannot be reset!

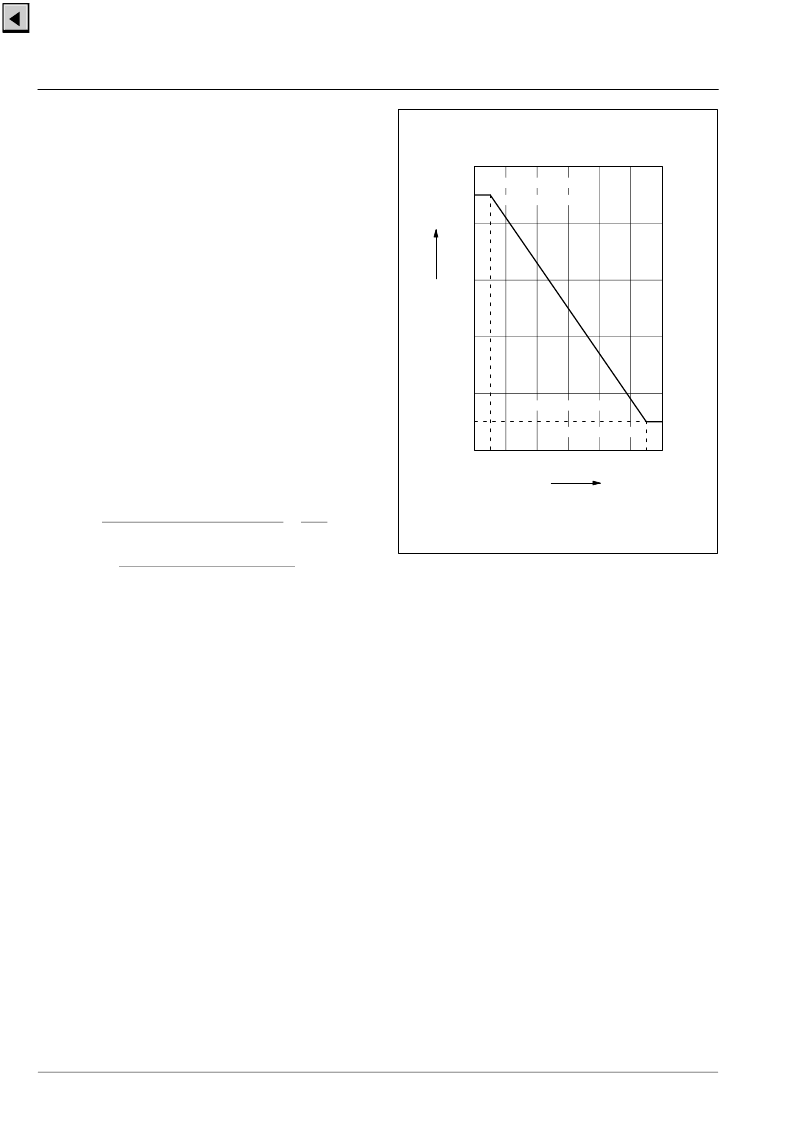

2.3.2. Calibration of the Angle Sensor

The following description explains the calibration pro-

cedure using an angle sensor as an example. The

required output characteristic is shown in Fig. 2

–

7.

–

the angle range is from

25

°

to 25

°

–

temperature coefficient of the magnet:

500 ppm/K

Step 1: Input of the registers which need not be

adjusted individually

The register values for the following registers are given

for all applications:

–

FILTER

Select the filter frequency: 500 Hz

–

RANGE

Select the magnetic field range: 30 mT

–

TC

For this magnetic material: 6

–

TCSQ

For this magnetic material: 14

–

CLAMP-LOW

For our example: 0.5 V

–

CLAMP-HIGH

For our example: 4.5 V

Enter these values in the software, and use the

“

write

and store

”

command for permanently writing the val-

ues in the registers.

Low clamping voltage

≤

V

OUT1,2

≤

High clamping voltage

V

OUT1

V

OUT2

ADC-READOUT1

ADC-READOUT2

Sensitivity =

V

DD

2048

*

ADC-READOUT1 * Sensitivity * V

DD

2048

V

OQ

= V

OUT1

0

–

30

1

2

3

4

5

–

20

–

10

0

10

20

30

°

V

Angle

V

OUT

Clamp-high = 4.5 V

Calibration point 1

Clamp-low = 0.5 V

Calibration point 2

Fig. 2

–

7:

Example for output characteristics

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| HAL805UT-K | Programmable Linear Hall Effect Sensor |

| HAL815 | Programmable Linear Hall Sensor |

| HAL815A | Programmable Linear Hall Sensor |

| HAL815E | Programmable Linear Hall Sensor |

| HAL815K | Programmable Linear Hall Sensor |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| HAL805UT-K | 制造商:MICRONAS 制造商全稱:MICRONAS 功能描述:Programmable Linear Hall Effect Sensor |

| HAL810 | 制造商:MICRONAS 制造商全稱:MICRONAS 功能描述:Programmable Linear Hall-Effect Sensor |

| HAL815 | 制造商:MICRONAS 制造商全稱:MICRONAS 功能描述:Programmable Linear Hall Sensor |

| HAL815_1 | 制造商:MICRONAS 制造商全稱:MICRONAS 功能描述:Programmable Linear Hall-Effect Sensor |

| HAL815A | 制造商:MICRONAS 制造商全稱:MICRONAS 功能描述:Programmable Linear Hall Sensor |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。