- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄377001 > DSP56F803E (飛思卡爾半導(dǎo)體(中國)有限公司) 16-bit Digital Signal Controllers PDF資料下載

參數(shù)資料

| 型號: | DSP56F803E |

| 廠商: | 飛思卡爾半導(dǎo)體(中國)有限公司 |

| 英文描述: | 16-bit Digital Signal Controllers |

| 中文描述: | 16位數(shù)字信號控制器 |

| 文件頁數(shù): | 17/52頁 |

| 文件大小: | 414K |

| 代理商: | DSP56F803E |

第1頁第2頁第3頁第4頁第5頁第6頁第7頁第8頁第9頁第10頁第11頁第12頁第13頁第14頁第15頁第16頁當(dāng)前第17頁第18頁第19頁第20頁第21頁第22頁第23頁第24頁第25頁第26頁第27頁第28頁第29頁第30頁第31頁第32頁第33頁第34頁第35頁第36頁第37頁第38頁第39頁第40頁第41頁第42頁第43頁第44頁第45頁第46頁第47頁第48頁第49頁第50頁第51頁第52頁

JTAG/OnCE

56F803 Technical Data, Rev. 15

Freescale Semiconductor

17

2.13 JTAG/OnCE

Part 3 Specifications

3.1 General Characteristics

The 56F803 is fabricated in high-density CMOS with 5-V tolerant TTL-compatible digital inputs. The

term “5-V tolerant” refers to the capability of an I/O pin, built on a 3.3V-compatible process technology,

to withstand a voltage up to 5.5V without damaging the device. Many systems have a mixture of devices

designed for 3.3V and 5V power supplies. In such systems, a bus may carry both 3.3V and 5V-compatible

I/O voltage levels (a standard 3.3V I/O is designed to receive a maximum voltage of 3.3V

±

10% during

normal operation without causing damage). This 5V-tolerant capability therefore offers the power savings

of 3.3V I/O levels while being able to receive 5V levels without being damaged.

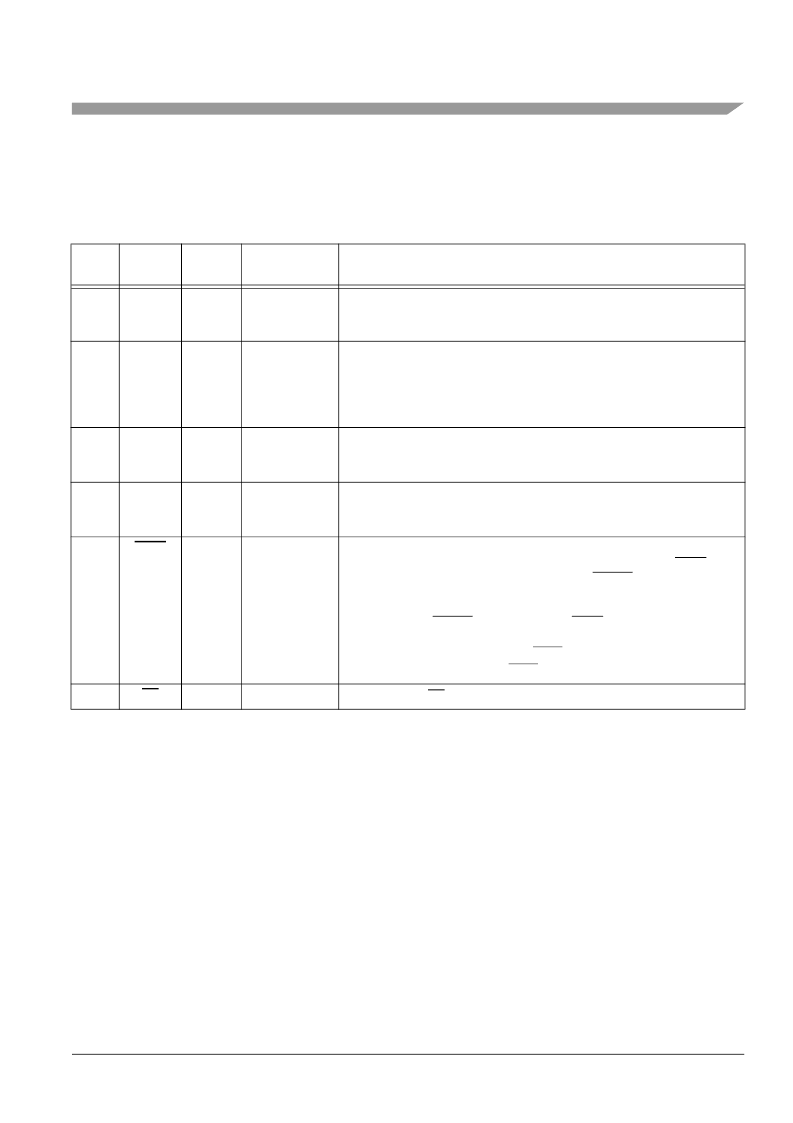

Table 2-17 JTAG/On-Chip Emulation (OnCE) Signals

No. of

Pins

Signal

Name

Signal

Type

State During

Reset

Signal Description

1

TCK

Input

(Schmitt)

Input, pulled low

internally

Test Clock Input

—This input pin provides a gated clock to synchronize the

test logic and shift serial data to the JTAG/OnCE port. The pin is connected

internally to a pull-down resistor.

1

TMS

Input

(Schmitt)

Input, pulled

high internally

Test Mode Select Input

—This input pin is used to sequence the JTAG

TAP controller’s state machine. It is sampled on the rising edge of TCK and

has an on-chip pull-up resistor.

Note:

Always tie the TMS pin to V

DD

through a 2.2K resistor.

1

TDI

Input

(Schmitt)

Input, pulled

high internally

Test Data Input

—This input pin provides a serial input data stream to the

JTAG/OnCE port. It is sampled on the rising edge of TCK and has an

on-chip pull-up resistor.

1

TDO

Output

Tri-stated

Test Data Output

—This tri-statable output pin provides a serial output data

stream from the JTAG/OnCE port. It is driven in the Shift-IR and Shift-DR

controller states, and changes on the falling edge of TCK.

1

TRST

Input

(Schmitt)

Input, pulled

high internally

Test Reset

—As an input, a low signal on this pin provides a reset signal to

the JTAG TAP controller. To ensure complete hardware reset, TRST

should be asserted at power-up and whenever RESET is asserted. The

only exception occurs in a debugging environment when a hardware device

reset is required and it is necessary not to reset the OnCE/JTAG module. In

this case, assert RESET, but do not assert TRST.

Note:

used in a debugging environment, TRST may be tied to V

SS

through a 1K resistor.

For normal operation, connect TRST directly to V

SS

. If the design is to be

1

DE

Output

Output

Debug Event

—DE provides a low pulse on recognized debug events.

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| DSP56F805E | 16-bit Digital Signal Controllers |

| DSP56F805FV80E | 16-bit Digital Signal Controllers |

| DSP56F805 | 16-bit Hybrid Controller(16位混合控制器) |

| DSP56F807PY80E | 16-bit Digital Signal Controllers |

| DSP56F807VF80E | 16-bit Digital Signal Controllers |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| DSP56F803EVM | 功能描述:開發(fā)板和工具包 - 其他處理器 Evaluation Kit For DSP56F803 RoHS:否 制造商:Freescale Semiconductor 產(chǎn)品:Development Systems 工具用于評估:P3041 核心:e500mc 接口類型:I2C, SPI, USB 工作電源電壓: |

| DSP56F803EVMUM | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:56F803 Evaluation Module Hardware User's Manual |

| DSP56F803PB | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:56F803 16-Bit Hybrid Controller Product Brief |

| DSP56F805 | 制造商:FREESCALE 制造商全稱:Freescale Semiconductor, Inc 功能描述:16-bit Digital Signal Controllers |

| DSP56F805ACIM | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:Targeting Document for the 56F805 3-Phase AC Induction Motor V/Hz Control |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。