- 您現(xiàn)在的位置:買(mǎi)賣(mài)IC網(wǎng) > PDF目錄67427 > FBMH4532HM202NT (TAIYO YUDEN CO LTD) 1 FUNCTIONS, 1.5 A, FERRITE CHIP PDF資料下載

參數(shù)資料

| 型號(hào): | FBMH4532HM202NT |

| 廠商: | TAIYO YUDEN CO LTD |

| 元件分類(lèi): | 數(shù)據(jù)傳輸濾波器 |

| 英文描述: | 1 FUNCTIONS, 1.5 A, FERRITE CHIP |

| 文件頁(yè)數(shù): | 27/67頁(yè) |

| 文件大?。?/td> | 5322K |

| 代理商: | FBMH4532HM202NT |

第1頁(yè)第2頁(yè)第3頁(yè)第4頁(yè)第5頁(yè)第6頁(yè)第7頁(yè)第8頁(yè)第9頁(yè)第10頁(yè)第11頁(yè)第12頁(yè)第13頁(yè)第14頁(yè)第15頁(yè)第16頁(yè)第17頁(yè)第18頁(yè)第19頁(yè)第20頁(yè)第21頁(yè)第22頁(yè)第23頁(yè)第24頁(yè)第25頁(yè)第26頁(yè)當(dāng)前第27頁(yè)第28頁(yè)第29頁(yè)第30頁(yè)第31頁(yè)第32頁(yè)第33頁(yè)第34頁(yè)第35頁(yè)第36頁(yè)第37頁(yè)第38頁(yè)第39頁(yè)第40頁(yè)第41頁(yè)第42頁(yè)第43頁(yè)第44頁(yè)第45頁(yè)第46頁(yè)第47頁(yè)第48頁(yè)第49頁(yè)第50頁(yè)第51頁(yè)第52頁(yè)第53頁(yè)第54頁(yè)第55頁(yè)第56頁(yè)第57頁(yè)第58頁(yè)第59頁(yè)第60頁(yè)第61頁(yè)第62頁(yè)第63頁(yè)第64頁(yè)第65頁(yè)第66頁(yè)第67頁(yè)

PRECAUTIONS

275

FERRITE

PRODUCTS

5

3/7

Technical considerations

Stages

Precautions

1. If the lower limit of the pick-up nozzle is low, too much force may be imposed

on the inductors, causing damage. To avoid this, the following points should

be considered before lowering the pick-up nozzle:

(1)The lower limit of the pick-up nozzle should be adjusted to the surface level of

the PC board after correcting for deflection of the board.

(2)The pick-up pressure should be adjusted between 1 and 3 N static loads.

(3)To reduce the amount of deflection of the board caused by impact of the pick-

up nozzle, supporting pins or back-up pins should be used under the PC board.

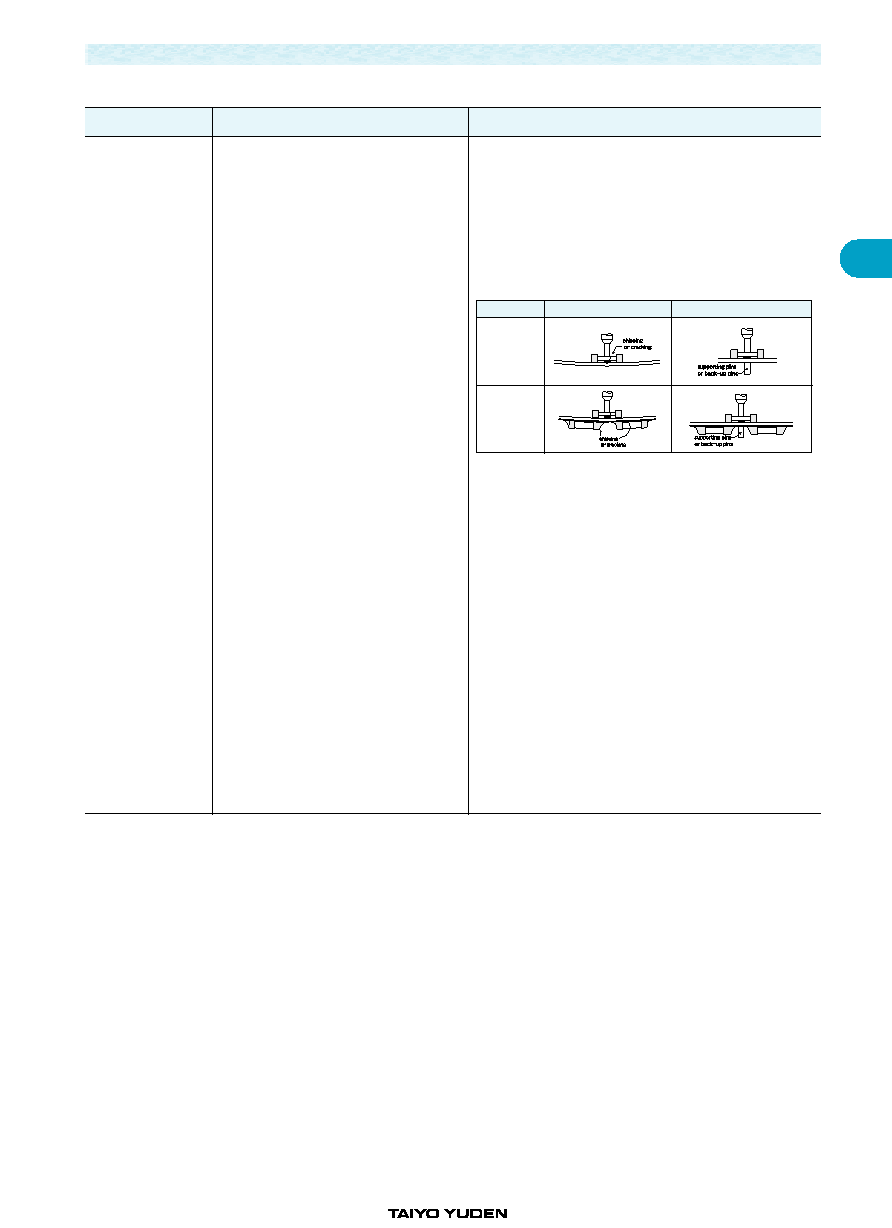

The following diagrams show some typical examples of good pick-up nozzle

placement:

Improper method

Proper method

2. As the alignment pin wears out, adjustment of the nozzle height can cause

chipping or cracking of the inductors because of mechanical impact on the

inductors. To avoid this, the monitoring of the width between the alignment pin

in the stopped position, and maintenance, inspection and replacement of the

pin should be conducted periodically.

S

Selection of Adhesives

1. Mounting inductors with adhesives in preliminary as-

sembly, before the soldering stage, may lead to de-

graded inductor characteristics unless the following

factors are appropriately checked; the size of land pat-

terns, type of adhesive, amount applied, hardening tem-

perature and hardening period. Therefore, it is impera-

tive to consult the manufacturer of the adhesives on

proper usage and amounts of adhesive to use.

1. Some adhesives may cause reduced insulation resistance. The difference

between the shrinkage percentage of the adhesive and that of the inductors

may result in stresses on the inductors and lead to cracking. Moreover, too

little or too much adhesive applied to the board may adversely affect compo-

nent placement, so the following precautions should be noted in the applica-

tion of adhesives.

(1)Required adhesive characteristics

a. The adhesive should be strong enough to hold parts on the board during the

mounting & solder process.

b. The adhesive should have sufficient strength at high temperatures.

c. The adhesive should have good coating and thickness consistency.

d. The adhesive should be used during its prescribed shelf life.

e. The adhesive should harden rapidly

f. The adhesive must not be contaminated.

g. The adhesive should have excellent insulation characteristics.

h. The adhesive should not be toxic and have no emission of toxic gasses.

3.Considerations for

automatic placement

S

Adjustment of mounting machine

1. Excessive impact load should not be imposed on the

inductors when mounting onto the PC boards.

2. The maintenance and inspection of the mounter should

be conducted periodically.

Double-sided

mounting

Single-sided mounting

Precautions on the use of Multilayer chip Inductors, Multilayer chip inductors for high frequency, Multilayer ferrite chip beads

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| FBR07HA121TB-00 | 1 FUNCTIONS, 7 A, FERRITE BEAD |

| FBR07HA850TB-00 | 1 FUNCTIONS, 7 A, FERRITE BEAD |

| FBR07VA121TB-00 | 1 FUNCTIONS, 7 A, FERRITE BEAD |

| FBR07VA850TB-00 | 1 FUNCTIONS, 7 A, FERRITE BEAD |

| FBR07HA121NB-00 | 1 FUNCTIONS, 7 A, FERRITE BEAD |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| FBMH4532HM202-T | 功能描述:電磁干擾濾波珠子、扼流圈和陣列 FER BD HI CUR CHIP 1812 2000OHMS 25% RoHS:否 制造商:AVX 阻抗: 最大直流電流:35 mA 最大直流電阻: 容差: 端接類(lèi)型:SMD/SMT 電壓額定值:25 V 工作溫度范圍:- 25 C to + 85 C 封裝 / 箱體:0603 (1608 metric) |

| FBMH4532HM681K | 制造商:KEMET 制造商全稱:Kemet Corporation 功能描述:Surface Mount Ferrite Products |

| FBMH4532HM681T | 制造商:TAIYO YUDE 功能描述:RoHS Compliant |

| FBMH4532HM681-T | 功能描述:電磁干擾濾波珠子、扼流圈和陣列 FER BD HI CUR CHIP 1812 680OHMS 25% RoHS:否 制造商:AVX 阻抗: 最大直流電流:35 mA 最大直流電阻: 容差: 端接類(lèi)型:SMD/SMT 電壓額定值:25 V 工作溫度范圍:- 25 C to + 85 C 封裝 / 箱體:0603 (1608 metric) |

| FBMH4532HM681-T | 制造商:TAIYO YUDEN 功能描述:Ferrite Chip Bead |

發(fā)布緊急采購(gòu),3分鐘左右您將得到回復(fù)。