- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄67412 > FAN5019MTCX_NL (FAIRCHILD SEMICONDUCTOR CORP) SWITCHING CONTROLLER, 4000 kHz SWITCHING FREQ-MAX, PDSO28 PDF資料下載

參數(shù)資料

| 型號(hào): | FAN5019MTCX_NL |

| 廠商: | FAIRCHILD SEMICONDUCTOR CORP |

| 元件分類: | 穩(wěn)壓器 |

| 英文描述: | SWITCHING CONTROLLER, 4000 kHz SWITCHING FREQ-MAX, PDSO28 |

| 封裝: | LEAD FREE, TSSOP-28 |

| 文件頁數(shù): | 13/30頁 |

| 文件大?。?/td> | 781K |

| 代理商: | FAN5019MTCX_NL |

第1頁第2頁第3頁第4頁第5頁第6頁第7頁第8頁第9頁第10頁第11頁第12頁當(dāng)前第13頁第14頁第15頁第16頁第17頁第18頁第19頁第20頁第21頁第22頁第23頁第24頁第25頁第26頁第27頁第28頁第29頁第30頁

FAN5019

PRODUCT SPECIFICATION

20

REV. 1.0.7 1/5/04

Selecting a Standard Inductor

The companies listed below can provide design consultation

and deliver power inductors optimized for high power

applications upon request.

Power Inductor Manufacturers

Coilcraft

(847)639-6400

www.coilcraft.com

Coiltronics

(561)752-5000

www.coiltronics.com

Sumida Electric Company

(510) 668-0660

www.sumida.com

Vishay Intertechnology

(402) 563-6866

www.vishay.com

Output Droop Resistance

The design requires that the regulator output voltage

measured at the CPU pins drops when the output current

increases. The specied voltage drop corresponds to a DC

output resistance (RO).

The output current is measured by summing together the

voltage across each inductor and then passing the signal

through a low-pass lter. This summer-lter is the CS

amplier congured with resistors RPH(X) (summers), and

RCS and CCS (lter). The output resistance of the regulator is

set by the following equations, where RL is the DCR of the

output inductors:

One has the exibility of choosing either RCS or RPH(X).

It is best to select RCS equal to 100k

, and then solve for

RPH(X) by rearranging Equation 6.

Next, use Equation 7 to solve for CCS:

It is best to have a dual location for CCS in the layout so stan-

dard values can be used in parallel to get as close to the value

desired. For this example, choosing CCS to be 4.7nF is a

good choice. For best accuracy, CCS should be a 5% or 10%

NPO capacitor. A close standard 1% value for RPH(X) is

100k

.

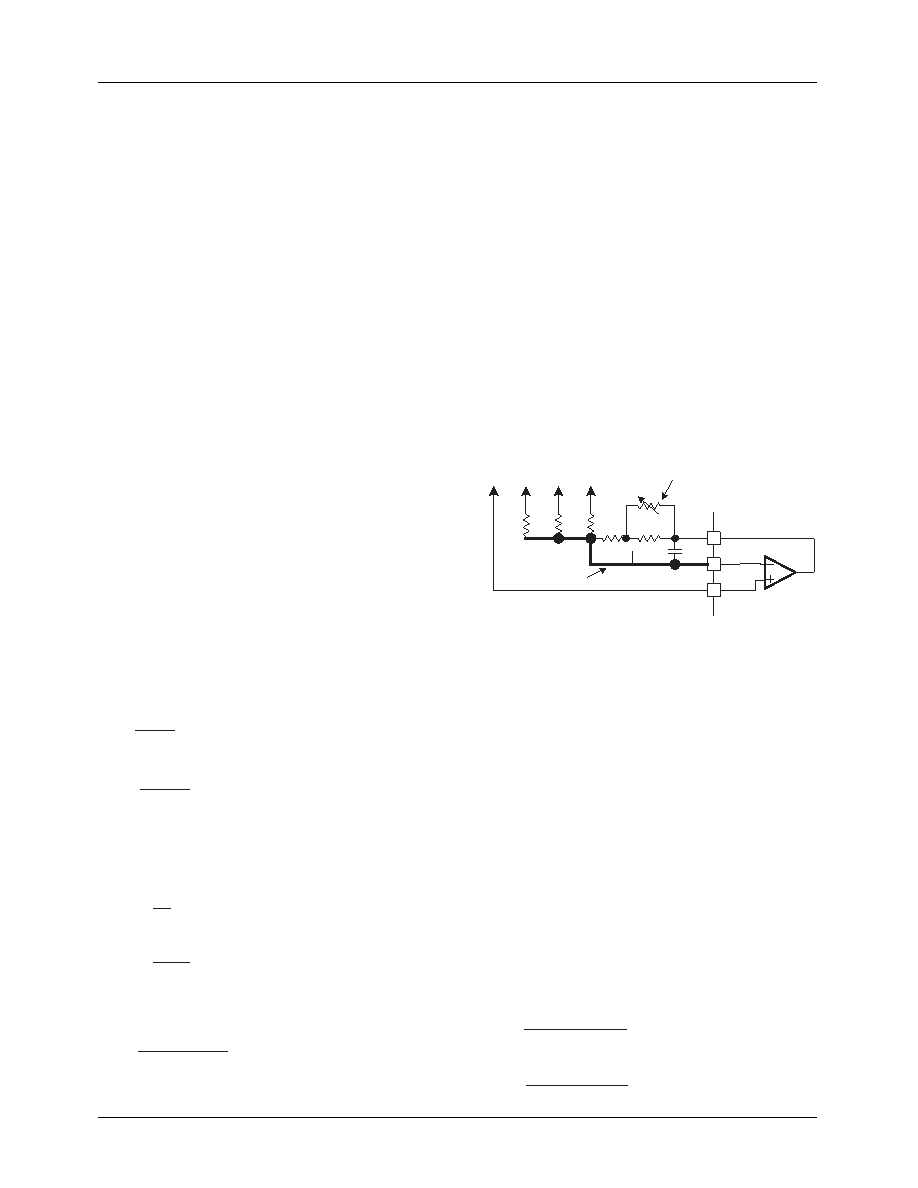

Inductor DCR Temperature Correction

With the inductor’s DCR being used as the sense element,

and copper wire being the source of the DCR, one needs to

compensate for temperature changes of the inductor’s wind-

ing. Fortunately, copper has a well-known temperature coef-

cient (TC) of 0.39%/°C.

If RCS is designed to have an opposite and equal percentage

change in resistance to that of the wire, it will cancel the

temperature variation of the inductor’s DCR. Due to the non-

linear nature of NTC thermistors, resistors RCS1 and RCS2

are needed (see Figure 5) to linearize the NTC and produce

the desired temperature tracking.

Figure 5. Temperature Compensation Circuit

The following procedure and expressions will yield values to

use for RCS1, RCS2, and RTH (the thermistor value at 25°C)

for a given RCS value.

1.

Select an NTC to be used based on type and value. Since

we do not have a value yet, start with a thermistor with a

value close to RCS. The NTC should also have an initial

tolerance of better than 5%.

2.

Based on the type of NTC, nd its relative resistance

value at two temperatures. The temperatures to use that

work well are 50°C and 90°C. We will call these resis-

tance values A (A is RTH(50°C)/RTH(25°C)) and B (B is

RTH(90°C)/RTH(25°C)). Note that the NTC’s relative value

is always 1 at 25°C.

3.

Next, nd the relative value of RCS required for each of

these temperatures. This is based on the percentage

change needed, which we will initially make 0.39%/°C.

We will call these r1 and r2 where:

L

X

PH

CS

O

R

×

=

)

(

(6)

CS

L

CS

R

L

C

×

=

(7)

CS

O

L

X

PH

R

×

=

)

(

=

×

=

k

m

R

X

PH

123

100

3

.

1

6

.

1

)

(

nF

k

m

nH

C

CS

06

.

4

100

6

.

1

650

=

×

=

18

17

16

CSREF

CSSUM

CSCOMP

CSA

C

CS

1.8nF

R

CS1

R

CS2

R

TH

R

PH1

R

PH3

R

PH2

Keep this path as

short as possible

and well away from

Switch Node lines

Place as close as

possible to nearest

inductor or low-side

MOSFET

To Switch Nodes

To V

OUT

sense

()

(

)

25

1

×

+

=

T

TC

r

()

(

)

25

1

2

×

+

=

T

TC

r

TC = 0.0039

T1 = 50°C

T2 = 90°C

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| FAN5037MX_NL | SWITCHING CONTROLLER, PDSO8 |

| FAN5037M_NL | SWITCHING CONTROLLER, PDSO8 |

| FAN5061M | SWITCHING CONTROLLER, 345 kHz SWITCHING FREQ-MAX, PDSO20 |

| FAN5201MSA | 6 A BATTERY CHARGE CONTROLLER, 275 kHz SWITCHING FREQ-MAX, PDSO24 |

| FAN5361UMP10X | SWITCHING REGULATOR, DSO6 |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| FAN501MPX | 制造商:Fairchild Semiconductor Corporation 功能描述:PWM CONTROLLER - Tape and Reel |

| FAN5020_AAC3116B WAF | 制造商:Fairchild Semiconductor Corporation 功能描述: |

| FAN5021_AAC3026B WAF | 制造商:Fairchild Semiconductor Corporation 功能描述: |

| FAN5026 | 制造商:FAIRCHILD 制造商全稱:Fairchild Semiconductor 功能描述:Dual DDR/Dual-output PWM Controller |

| FAN5026_11 | 制造商:FAIRCHILD 制造商全稱:Fairchild Semiconductor 功能描述:Dual DDR / Dual-Output PWM Controller |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。