- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄272835 > TXS100ZY-P2 (POWER-ONE INC) 1-OUTPUT 120 W DC-DC REG PWR SUPPLY MODULE PDF資料下載

參數(shù)資料

| 型號: | TXS100ZY-P2 |

| 廠商: | POWER-ONE INC |

| 元件分類: | 電源模塊 |

| 英文描述: | 1-OUTPUT 120 W DC-DC REG PWR SUPPLY MODULE |

| 封裝: | 2.400 X 3.450 INCH, 0.500 INCH HEIGHT, 3/4 BRICK PACKAGE-14 |

| 文件頁數(shù): | 16/27頁 |

| 文件大?。?/td> | 2635K |

| 代理商: | TXS100ZY-P2 |

第1頁第2頁第3頁第4頁第5頁第6頁第7頁第8頁第9頁第10頁第11頁第12頁第13頁第14頁第15頁當(dāng)前第16頁第17頁第18頁第19頁第20頁第21頁第22頁第23頁第24頁第25頁第26頁第27頁

Product Specification

TXS Series: 75…120 A DC-DC Converters

36 to 75 V DC Input, 1.2, 1.5, 1.8, 2.0 and 2.5 V Output, 90 W to 250 W

REV. FEB 18, 2003

23 of 27

www.power-one.com

Thermal Considerations

TXS converters achieve one of the highest current

and power densities on the market. This would be

useless, if in practise the available current should

be reduced a lot because of cooling problems.

But TXS converters achieve also the highest full

load efficiency on the market and use a unique

thermal design which makes them to real high

density, high current converters.

Maximum Base Plate Temperature

To ensure reliable long term operation, and to

comply with safety agency requirements, the base

plate temperature (TBP) should always be kept

below

100 °C.

The

maximum

base

plate

temperature is defined by two conditions:

Maximum multilayer temperature

≤ 120 °C.

(UL 130 °C print material is used: Power-One

designs use normally 10 K safety margin).

Maximum opto-coupler temperature

≤ 100 °C.

(Device limits, otherwise accelerated aging)

If the base plate temperature stays below 100 °C,

both of the above limits are kept under all

operating and cooling conditions.

The maximum base plate temperature is limited by

the temperature protection, but should be verified

after system integration. TBP can be measured on

the temperature measuring point on the base

plate. See mechanical drawing for location.

Thermal Resistance

To operate the converters below the maximum

base plate temperature, sufficient cooling should

be provided. The modules can be cooled by

conduction, convection and radiation to the

surrounding environment.

The path for the heat transport can be described

with a thermal resistance. A low thermal

resistance allows a lot of heat or loss to flow from a

hot component x to the surrounding y.

Rthxy = (Tx - Ty) / PLoss

[K/W]

The thermal resistance between x and y is defined

as temperature difference between the two parts,

divided through the amount of loss flowing from the

hot to the cool part (see report “Thermal

performace of TXS” on the TXS product CD ROM

for further information).

TXS provide two main ways for heat transport:

Heat can be transported to the motherboard and to

ambient.

Base Plate to Motherboard RthBP-PCB

TXS converters provide an efficient way to

transport heat to the motherboard over the pins

and the case. Since the efficiency of this method

varies from design to design, it can’t be predicted.

(See report: “TXS layout considerations”)

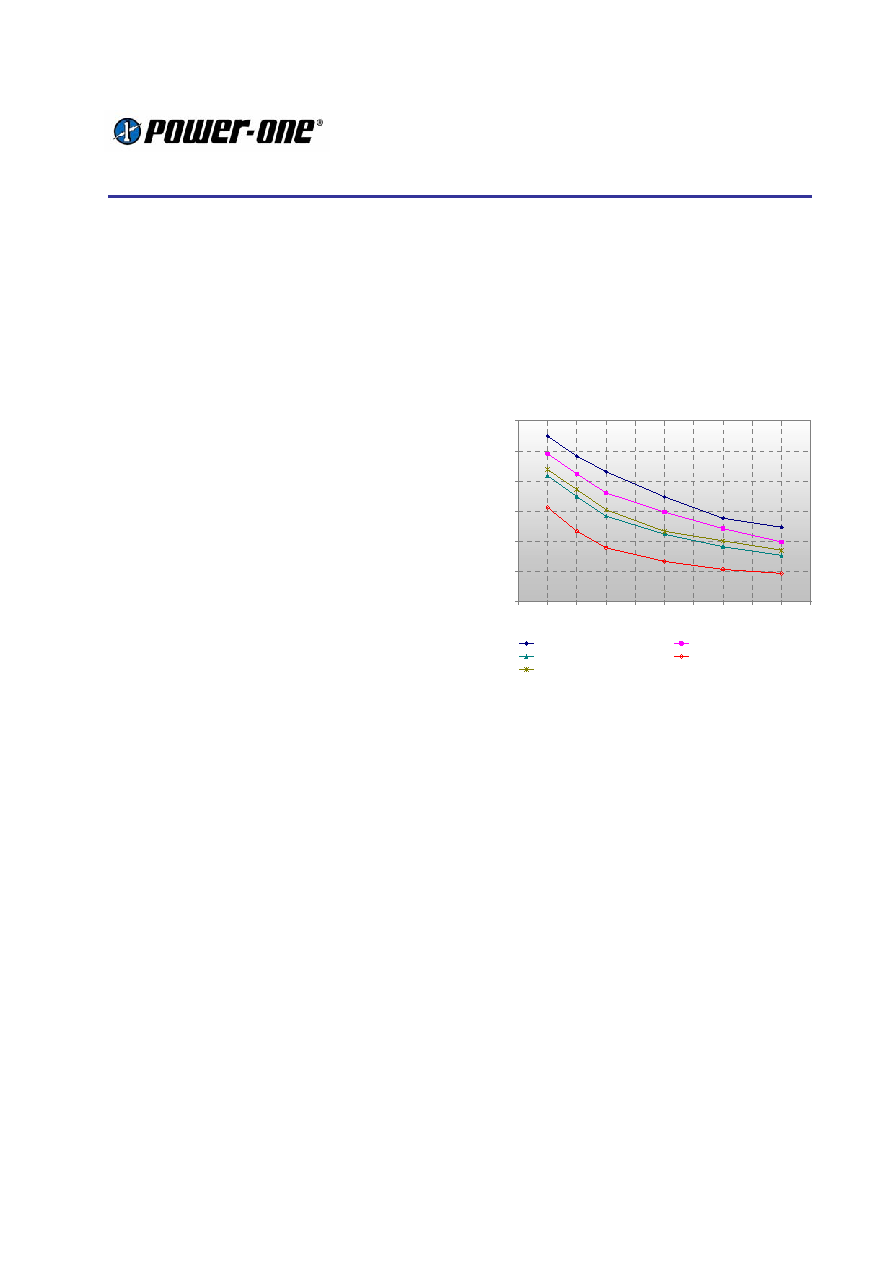

Base Plate to Ambient RthBP-A

TXS modules are designed for forced convection

cooling. To estimate the thermal resistance at

different airflows the following graph can be used:

Thermal Resistance v's Air-Flow Rate

0.00

0.50

1.00

1.50

2.00

2.50

3.00

50

100

150

200

250

300

350

400

450

500

550

Air-Flow Rate (LFM)

Rth

(K/

W

)

Without Heat Sink

6.1mm (0.24'') Heat Sink

13mm (0.51'') Heat Sink (CUT)

24.1mm (0.95'') Heat Sink

11.4mm (0.45'') Heat Sink

Figure 53:

Thermal resistances at laminar airflow

TXS modules are designed to work without

additional heat sink. But it is possible to attach an

external heat sink to the base plate.

Heat sinks can efficiently help to increase the

thermal safety margin or to increase the available

power if the available airflow in a system is not

sufficient.

Calculation of the Required Airflow

The thermal resistance RthBP-A allows determining

the required airflow or heat sink, for a given

ambient temperature and operating condition.

1

The operating conditions define the loss of the

converter: Loss figures for different output

voltages, input voltage ranges, and output

currents can be found on page 8. They should

be corrected with the factors of Table 7 for the

targeted base plate temperature.

2

The required thermal resistance for a given

environment (TBP, TA) and loss can be

calculated using the formula from above:

RthBP-A = (TBP -TA) / PLoss. To remember: The

base plate temperature should not be

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| TXS120ZA-N2V | 1-OUTPUT 180 W DC-DC REG PWR SUPPLY MODULE |

| TXS120ZA-R3H | 1-OUTPUT 180 W DC-DC REG PWR SUPPLY MODULE |

| TXS120ZY-P21V | 1-OUTPUT 144 W DC-DC REG PWR SUPPLY MODULE |

| TXS75ZY-P2R2V | 1-OUTPUT 90 W DC-DC REG PWR SUPPLY MODULE |

| TXS80ZD-3V | 1-OUTPUT 200 W DC-DC REG PWR SUPPLY MODULE |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| TXS10AU08AI | 制造商:TE Connectivity 功能描述: |

| TXS10AU12AI | 功能描述:環(huán)形MIL規(guī)格應(yīng)變消除裝置與適配器 ADAPTER: RoHS:否 制造商:Amphenol Industrial 產(chǎn)品:Cable Clamps 類型:Bushing Cable Clamps MIL 類型:MIL-DTL-5015 系列:97 外殼大小:16S, 16 匹配樣式:Threaded 主體材料:Aluminum Alloy 主體類型:Straight |

| TXS10P-100A | 制造商:TOPSTEK 制造商全稱:TOPSTEK 功能描述:Anti-Magnet AC Current Sensors |

| TXS18X | 制造商:YSTONE 制造商全稱:Yellow Stone Corp 功能描述:TAPED LED LAMP |

| TXS2-1.5V | 功能描述:低信號繼電器 - PCB 2 Form C 2A 30VDC 1.5VDC RoHS:否 制造商:NEC 觸點形式:2 Form C (DPDT-BM) 觸點電流額定值: 線圈電壓:5 V 最大開關(guān)電流:1 A 線圈電流:1 A 線圈類型:Non-Latching 功耗:140 mW 端接類型:SMT 絕緣: 介入損耗: |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。