- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄370954 > M3851 (Mitsubishi Electric Corporation) Single Chip 8 Bits Microcomputer(8位單片機) PDF資料下載

參數(shù)資料

| 型號: | M3851 |

| 廠商: | Mitsubishi Electric Corporation |

| 英文描述: | Single Chip 8 Bits Microcomputer(8位單片機) |

| 中文描述: | 單芯片8位單片機(8位單片機) |

| 文件頁數(shù): | 26/61頁 |

| 文件大小: | 904K |

| 代理商: | M3851 |

第1頁第2頁第3頁第4頁第5頁第6頁第7頁第8頁第9頁第10頁第11頁第12頁第13頁第14頁第15頁第16頁第17頁第18頁第19頁第20頁第21頁第22頁第23頁第24頁第25頁當(dāng)前第26頁第27頁第28頁第29頁第30頁第31頁第32頁第33頁第34頁第35頁第36頁第37頁第38頁第39頁第40頁第41頁第42頁第43頁第44頁第45頁第46頁第47頁第48頁第49頁第50頁第51頁第52頁第53頁第54頁第55頁第56頁第57頁第58頁第59頁第60頁第61頁

26

3851 Group

SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER

MITSUBISHI MICROCOMPUTERS

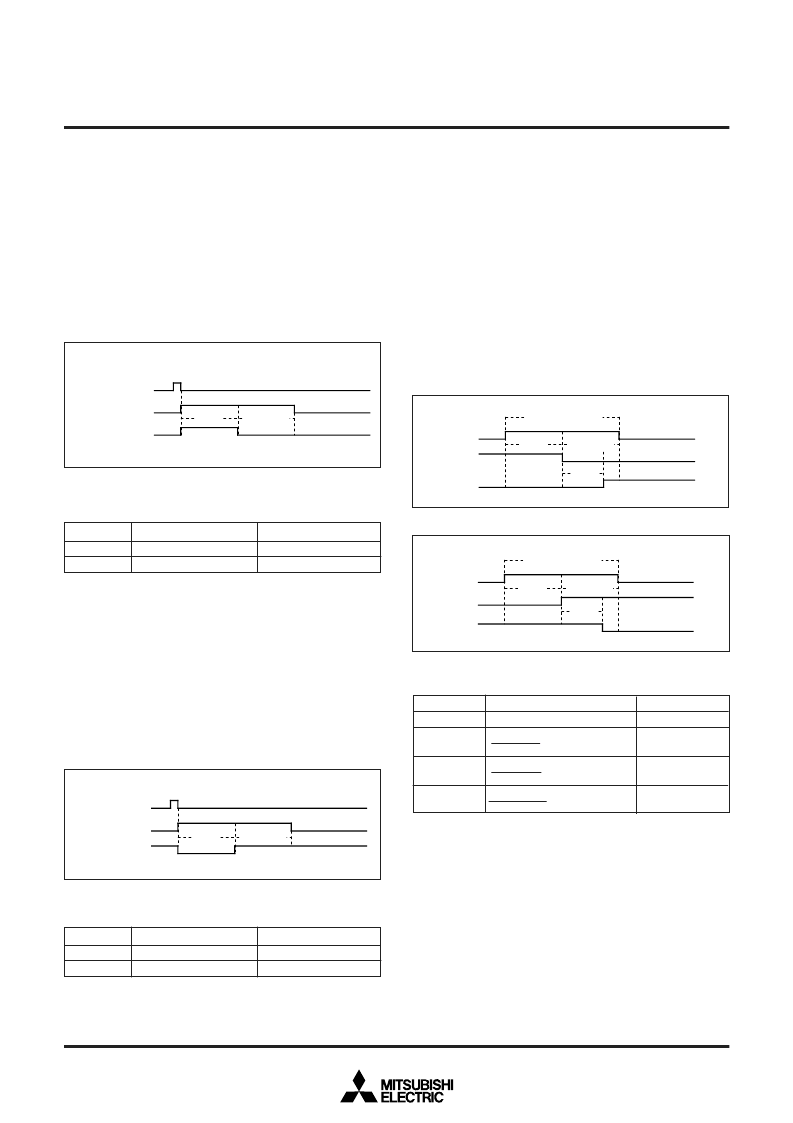

Fig. 28 START/STOP condition detecting timing diagram

START/STOP Condition Detecting Operation

The START/STOP condition detection operations are shown in

Figures 28, 29, and Table 8. The START/STOP condition is set by

the START/STOP condition set bit.

The START/STOP condition can be detected only when the input

signal of the S

CL

and S

DA

pins satisfy three conditions: S

CL

re-

lease time, setup time, and hold time (see Table 8).

The BB flag is set to “1” by detecting the START condition and is

reset to “0” by detecting the STOP condition.

The BB flag set/reset timing is different in the standard clock mode

and the high-speed clock mode. Refer to Table 8, the BB flag set/

reset time.

Note:

When a STOP condition is detected in the slave mode (MST = 0), an

interrupt request signal “IICIRQ” occurs to the CPU.

START Condition Generating Method

When writing “1” to the MST, TRX, and BB bits of the I

2

C status

register (address 002D

16

) at the same time after writing the slave

address to the I

2

C data shift register (address 002B

16

) with the

condition in which the ES0 bit of the I

2

C control register (address

002E

16

) and the BB flag are “0”, a START condition occurs. After

that, the bit counter becomes “000

2

” and an S

CL

for 1 byte is out-

put. The START condition generating timing is different in the

standard clock mode and the high-speed clock mode. Refer to

Figure 26, the START condition generating timing diagram, and

Table 6, the START condition generating timing table.

STOP Condition Generating Method

When the ES0 bit of the I

2

C control register (address 002E

16

) is

“1,” write “1” to the MST and TRX bits, and write “0” to the BB bit

of the I

2

C status register (address 002D

16

) simultaneously. Then a

STOP condition occurs. The STOP condition generating timing is

different in the standard clock mode and the high-speed clock

mode. Refer to Figure 27, the STOP condition generating timing

diagram, and Table 7, the STOP condition generating timing table.

Fig. 26 START condition generating timing diagram

Fig. 27 STOP condition generating timing diagram

Table 7 STOP condition generating timing table

Item

Setup time

Hold time

4.5

μ

s (18 cycles)

Standard clock mode

5.0

μ

s (20 cycles)

Note:

Absolute time at

φ

= 4 MHz. The value in parentheses denotes the

number of

φ

cycles.

High-speed clock mode

3.0

μ

s (12 cycles)

2.5

μ

s (10 cycles)

Table 6 START condition generating timing table

Item

Setup time

Hold time

5.0

μ

s (20 cycles)

Standard clock mode

5.0

μ

s (20 cycles)

Note:

Absolute time at

φ

= 4 MHz. The value in parentheses denotes the

number of

φ

cycles.

High-speed clock mode

2.5

μ

s (10 cycles)

2.5

μ

s (10 cycles)

Table 8 START condition/STOP condition detecting conditions

Standard clock mode

SCC value + 1 cycle (6.25

μ

s)

Note:

Unit : Cycle number of system clock

φ

SSC value is the decimal notation value of the START/STOP condi-

tion set bits SSC4 to SSC0. Do not set “0” or an odd number to SSC

value. The value in parentheses is an example when the I

2

C START/

STOP condition control register is set to “18

16

” at

φ

= 4 MHz.

Fig. 29 STOP condition detecting timing diagram

S

CL

release time

High-speed clock mode

4 cycles (1.0

μ

s)

2 cycles (1.0

μ

s)

2 cycles (0.5

μ

s)

3.5 cycles (0.875

μ

s)

SCC value + 1

2

SCC value + 1

2

SCC value –1

2

Setup time

Hold time

BB flag set/

reset time

cycle

< 4.0

μ

s (3.125

μ

s)

cycle

< 4.0

μ

s (3.125

μ

s)

+ 2 cycles (3.375

μ

s)

I

2

C status register

write signal

Hold time

Setup

time

S

CL

S

DA

I

2

C status register

write signal

Hold time

Setup

time

S

CL

S

DA

Hold time

Setup

time

S

CL

S

DA

BB flag

S

CL

release time

BB flag

reset

Hold time

Setup

time

S

CL

S

DA

BB flag

S

CL

release time

BB flag

reset

time

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| M38512M4 | SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER |

| M388504E6SP | SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER |

| M388504E6SS | SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER |

| M3850 | Single Chip 8 Bits Microcomputer(8位單片機) |

| M388504E6FP | SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| M3851 BK001 | 制造商:Alpha Wire Company 功能描述:CBL 7COND 14AWG BLK 1000' |

| M3851 BK002 | 制造商:Alpha Wire Company 功能描述:CBL 7COND 14AWG BLK 500' |

| M3851 BK005 | 制造商:Alpha Wire Company 功能描述:CBL 7COND 14AWG BLK 100' |

| M38510/00102BCB | 制造商:n/a 功能描述:38510/00102 S6I6B 制造商: 功能描述: 制造商:undefined 功能描述: |

| M38510/00103BCA | 制造商:QP Semiconductor 功能描述:NAND GATE, TRIPLE 3-INPUT |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。