- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄97907 > ELH0101 Power Operational Amplifier PDF資料下載

參數(shù)資料

| 型號: | ELH0101 |

| 元件分類: | 運算放大器 |

| 英文描述: | Power Operational Amplifier |

| 中文描述: | 功率運算放大器 |

| 文件頁數(shù): | 2/16頁 |

| 文件大小: | 326K |

| 代理商: | ELH0101 |

ELH010188385089012YX

Power Operational Amplifier

Applications Information

Contd

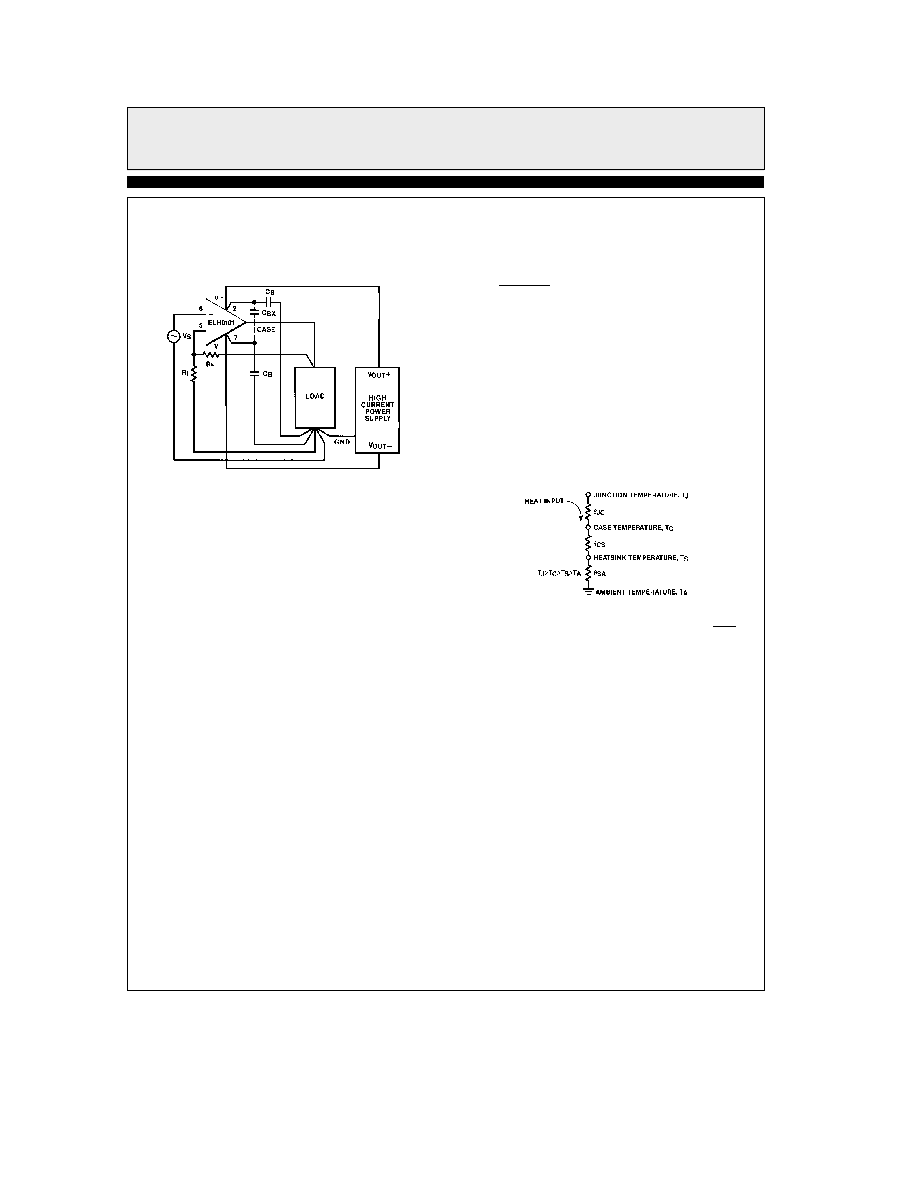

Every attempt should be made to achieve a sin-

gle point ground system as shown in the figure

below

0101 – 14

Bypass capacitor CBX should be used if the lead

lengths of bypass capacitors CB are long If a sin-

gle point ground system is not possible keep sig-

nal load and power supply from intermingling

as much as possible For further information on

proper grounding techniques refer to ‘‘Grounding

and Shielding Techniques in Instrumentation’’

by Morrison and ‘‘Noise Reduction Techniques

in Electronic Systems’’ by Ott (both published

by John Wiley and Sons)

Leads or PC board traces to the supply pins

short circuit current limit pins and the output

pin must be substantial enough to handle the

high currents that the ELH0101 is capable of

producing

Short Circuit Current Limiting

Should current limiting of the output not be nec-

essary SCa should be shorted to Va and SCb

should be shorted to Vb Remember that the

short circuit current limit is dependent upon the

total resistance seen between the supply and cur-

rent limit pins This total resistance includes the

desired resistor plus leads PC Board traces and

solder joints

Assuming a zero TCR current lim-

it resistor typical temperature coefficient of the

short circuit will be approximately 03%

Thermal Resistance

The thermal resistance between two points of a

conductive system is expressed as

i12 e

T1 b T2

PD

CW

(1)

where subscript order indicates the direction of

heat flow A simplified heat transfer circuit for a

cased semiconductor and heatsink system is

shown in the figure below

The circuit is valid only if the system is in ther-

mal equilibrium (constant heat flow) and there

are indeed single specific temperatures TJ TC

and TS (no temperature distribution in junction

case or heatsink) Nevertheless this is a reason-

able approximation of actual performance

0101 – 15

Short circuit current will be limited to approximately

06

RSC

The junction-to-case thermal resistance

iJC

specified in the data sheet depends upon the ma-

terial and size of the package die size and thick-

ness and quality of the die bond to the case or

lead frame The case-to-heatsink thermal resist-

ance

iCS depends on the mounting of the device

to the heatsink and upon the area and quality of

the contact surface Typical

iCS for a TO-3 pack-

age is 05 CW to 07 CW

and 03 CW to

05 CW using silicone grease

The heatsink to ambient thermal resistance

iSA

depends on the quality of the heatsink and the

ambient conditions

10

相關PDF資料 |

PDF描述 |

|---|---|

| ELH0101AK | Power Operational Amplifier |

| ELH0101K | Power Operational Amplifier |

| EM-SERIES | ASIC |

| EM08MR32UM | Dual Regulator-Synchronous Rectified Buck PWM and Linear Power Controller; Temperature Range: 0°C to 70°C; Package: 16-QFN |

| EM22003 | ACPI Regulator/Controller for Dual Channel DDR Memory Systems; Temperature Range: 0°C to 70°C; Package: 20-QFN |

相關代理商/技術參數(shù) |

參數(shù)描述 |

|---|---|

| ELH0101ACK | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:Voltage-Feedback Operational Amplifier |

| ELH0101ACK/E+ | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:Voltage-Feedback Operational Amplifier |

| ELH0101AK | 制造商:ELANTEC 制造商全稱:ELANTEC 功能描述:Power Operational Amplifier |

| ELH0101AK/883B | 制造商:E 功能描述: |

| ELH0101CK | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:Voltage-Feedback Operational Amplifier |

發(fā)布緊急采購,3分鐘左右您將得到回復。