- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄378403 > AN-994-1 (International Rectifier) MAXIMIZING THE EFFECTIVENESS OF YOUR SMD ASSEMBLIES PDF資料下載

參數(shù)資料

| 型號: | AN-994-1 |

| 廠商: | International Rectifier |

| 英文描述: | MAXIMIZING THE EFFECTIVENESS OF YOUR SMD ASSEMBLIES |

| 中文描述: | 最大限度地發(fā)揮你的貼片組件效果 |

| 文件頁數(shù): | 5/7頁 |

| 文件大?。?/td> | 120K |

| 代理商: | AN-994-1 |

5 of 7

150

Section IV: Solder Pastes:

There are a wide variety of solder pastes available for

surface mounting applications. Typical solder pastes

are composed of a homogeneous mixture of pre

alloyed solder powder with a specific grain size.

Fluxes are also provided in the solder paste mixture as

a necessary component of the surface mounting

process.

In today’s densely populated assemblies, pin spacing

of SMD components has significantly been reduced.

Pin spacing of less than 0.4mm is common which

poses problem such as solder bridging, insufficient

solder on the lead and device placement accuracy.

Solder stencil thickness, dimension and registration

accuracy, solder paste composition and particle size

are all critical to successful soldering of these

assemblies.

With the advanced state of the art of fine pitch device

technology, a simple guideline for the choice of solder

paste is outside the scope of this document. The

customer should seek expert guidance from the solder

paste vendor and PCB board fabricator for detailed,

application specific recommendations.

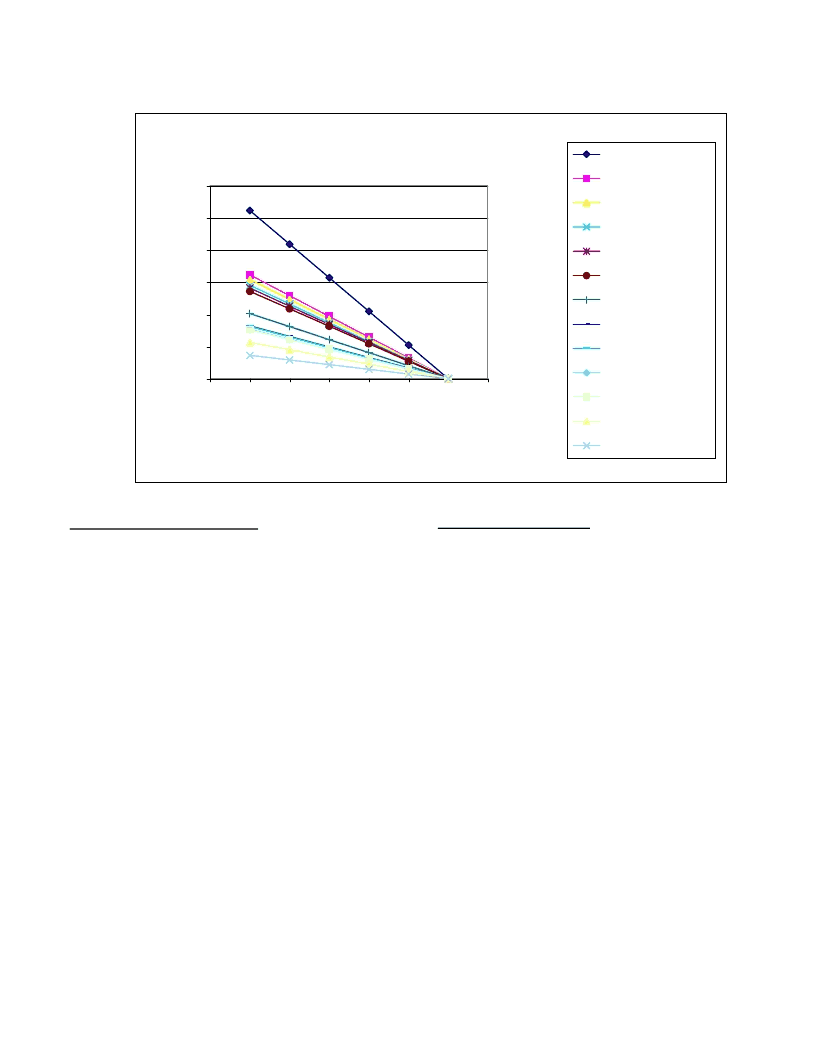

Power Dissipation vs. Ambient Temperature

Absolute Minimum PCB footprint

0.00

0.50

1.00

1.50

2.00

2.50

3.00

0

25

50

75

100

125

175

T_ambient(°C)

P

D2-Pak **

D-Pak **

mid-can DirectFET **

SOT-223

small-can DirectFET **

SO-8

SO-8 (Dual)

TSSOP8

TSOP6 (Single)

u-6

u-8

TSOP6 (Dual)

u-3

Figure 4:

Absolute Min Power Dissipation (T ambient)

Section III: Attachment to board:

Most designers and technicians in the electronic industry are

familiar with printed circuits that are provided with holes to

support leaded components during the soldering process.

Surface mount components on the other hand are by

definition leadless and rely on the strength of the solder joint

alone for mechanical as well as electrical connection. Many

PCB assemblies require the mounting of devices on both

sides of the board. The reflow process is typically performed

once. Both sides of the board are pasted at the same time.

Components are then placed on the topside only. An

adhesive is then applied to the topside to hold the

components in place. The board is then inverted 180

degrees and the second side is populated with components.

At that point the populated board is ready for the thermal

process that will melt the solder paste and attach the

components to the board. After the mounting process is

complete the adhesive serves no further purpose.

The adhesives used must provide sufficient tenacity to

prevent component movement during handling and soldering.

At the same time, the adhesive should provide a bond that

can be broken with minimal disturbance to the populated

board in order to replace incorrect components before

soldering. It must also be capable of maintaining adhesion

during the preheat cycle and it should not become a deterrent

to solder flow during the reflow or wave soldering process.

Typical adhesives of this type are made from non-activated

resins (R), which can be used in forming gas atmosphere to

reduce oxides. Some are mildly activated resin (RMA), which

can be used in normal factory environment. The activation in

this case is used to reduce

small amounts of oxidation of the

solderable surfaces and the solder particles in the paste.

相關PDF資料 |

PDF描述 |

|---|---|

| AN-CC1002 | Design Considerations for ISD1700 Family |

| AN013 | JT 128C 128#22D SKT RECP |

| AN1025 | Converting A 5.0V Supply Rail To A Regulated 3.0V |

| AN1034 | Analog Switch and Multiplexer Applications |

| AN1042 | High Fidelity Switching Audio Amplifiers Using TMOS Power MOSFETs |

相關代理商/技術參數(shù) |

參數(shù)描述 |

|---|---|

| AN-995A | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:Electronic Ballasts Using the Cost-Saving IR215X Drivers(153.99 k) |

| AN-996 | 制造商:FAIRCHILD 制造商全稱:Fairchild Semiconductor 功能描述:Using the Fairchild FST Bus Switch as a 5V to 3V Translator |

| AN9C10A | 制造商: 功能描述: 制造商:undefined 功能描述: |

| AN9D | 制造商:PANASONIC 制造商全稱:Panasonic Semiconductor 功能描述:Analog master slice IC series |

| AN9DA00 | 制造商:PANASONIC 制造商全稱:Panasonic Semiconductor 功能描述:Analog master slice IC series |

發(fā)布緊急采購,3分鐘左右您將得到回復。