- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄375225 > AC12EGML Thyristor Product Catalog PDF資料下載

參數(shù)資料

| 型號: | AC12EGML |

| 英文描述: | Thyristor Product Catalog |

| 中文描述: | 晶閘管產(chǎn)品目錄 |

| 文件頁數(shù): | 164/224頁 |

| 文件大小: | 2697K |

| 代理商: | AC12EGML |

第1頁第2頁第3頁第4頁第5頁第6頁第7頁第8頁第9頁第10頁第11頁第12頁第13頁第14頁第15頁第16頁第17頁第18頁第19頁第20頁第21頁第22頁第23頁第24頁第25頁第26頁第27頁第28頁第29頁第30頁第31頁第32頁第33頁第34頁第35頁第36頁第37頁第38頁第39頁第40頁第41頁第42頁第43頁第44頁第45頁第46頁第47頁第48頁第49頁第50頁第51頁第52頁第53頁第54頁第55頁第56頁第57頁第58頁第59頁第60頁第61頁第62頁第63頁第64頁第65頁第66頁第67頁第68頁第69頁第70頁第71頁第72頁第73頁第74頁第75頁第76頁第77頁第78頁第79頁第80頁第81頁第82頁第83頁第84頁第85頁第86頁第87頁第88頁第89頁第90頁第91頁第92頁第93頁第94頁第95頁第96頁第97頁第98頁第99頁第100頁第101頁第102頁第103頁第104頁第105頁第106頁第107頁第108頁第109頁第110頁第111頁第112頁第113頁第114頁第115頁第116頁第117頁第118頁第119頁第120頁第121頁第122頁第123頁第124頁第125頁第126頁第127頁第128頁第129頁第130頁第131頁第132頁第133頁第134頁第135頁第136頁第137頁第138頁第139頁第140頁第141頁第142頁第143頁第144頁第145頁第146頁第147頁第148頁第149頁第150頁第151頁第152頁第153頁第154頁第155頁第156頁第157頁第158頁第159頁第160頁第161頁第162頁第163頁當前第164頁第165頁第166頁第167頁第168頁第169頁第170頁第171頁第172頁第173頁第174頁第175頁第176頁第177頁第178頁第179頁第180頁第181頁第182頁第183頁第184頁第185頁第186頁第187頁第188頁第189頁第190頁第191頁第192頁第193頁第194頁第195頁第196頁第197頁第198頁第199頁第200頁第201頁第202頁第203頁第204頁第205頁第206頁第207頁第208頁第209頁第210頁第211頁第212頁第213頁第214頁第215頁第216頁第217頁第218頁第219頁第220頁第221頁第222頁第223頁第224頁

AN1006

Application Notes

http://www.teccor.com

+1 972-580-7777

AN1006 - 12

2002 Teccor Electronics

Thyristor Product Catalog

7. Set

Terminal Selector

to

Emitter Grounded-Open Base

.

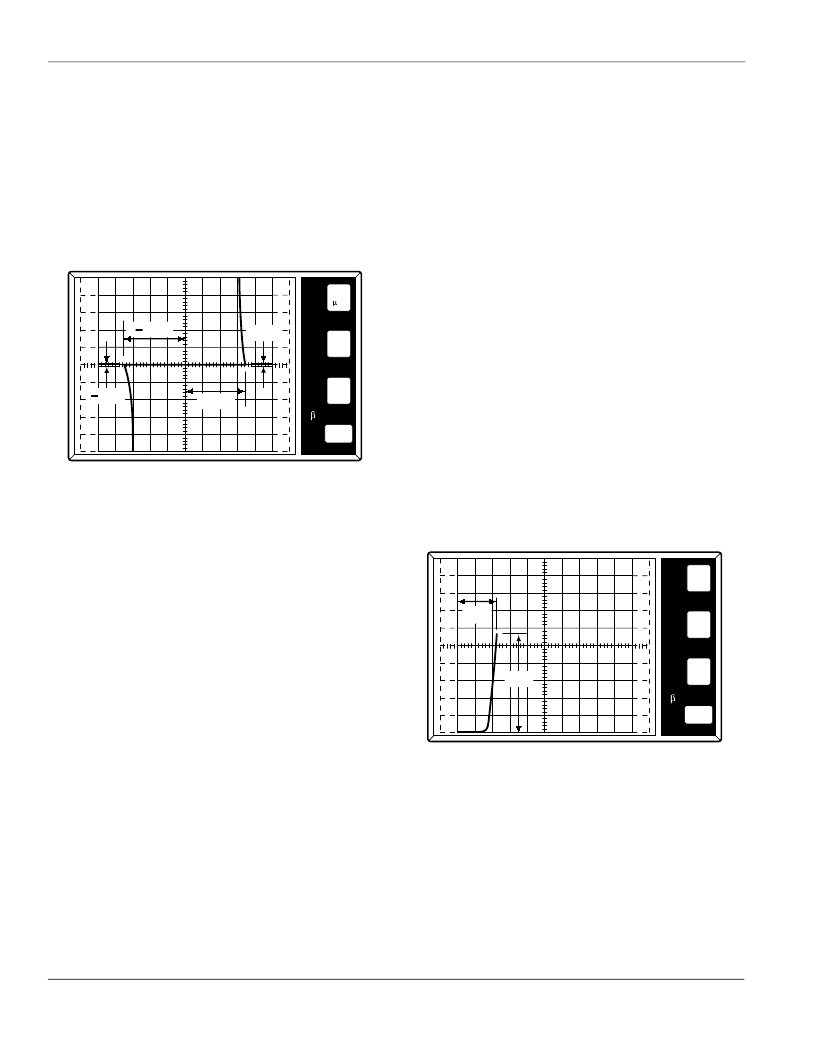

Procedure 5: V

BO (Positive and Negative)

To measure the V

BO (Positive and Negative)

parameter:

1. Set

Left-Right Terminal Jack Selector

to correspond with

the location of the test fixture.

2. Set

Variable Collector Supply Voltage

to

55 V

(

65 V

on

370) and apply voltage to the device under test (D.U.T.)

using the

Left Hand Selector Switch.

The peak voltage at

which current begins to flow is the V

BO

value.

(Figure AN1006.19)

Figure AN1006.19 (+)V

BO

= 35 V; (-)V

BO

= 36 V; (±)I

BO

< 10 A

Procedure 6: I

BO (Positive and Negative)

To measure the I

BO (Positive and Negative)

parameter, at the V

BO

point,

measure the amount of device current just before the device

reaches the breakover point. The measured current at this point

is the I

BO

value.

Note: If I

is less than 10 μA, the current cannot readily be seen

on curve tracer.

Procedure 7:

V

BO (Voltage Breakover Symmetry)

To measure the

V

BO (Voltage Breakover Symmetry)

parameter:

1. Measure positive and negative V

BO

values per Procedure 5.

2. Subtract the absolute value of V

BO

(-) from V

BO

(+).

The absolute value of the result is:

V

BO

= [ I+V

BO

I - I -V

BO

I ]

Procedure 8: V

TM (Forward and Reverse)

To test V

TM

, the

Quadrac

must be connected the same as when

testing V

BO

, I

BO

, and

V

BO

.

To connect the

Quadrac

:

1. Connect

MT1

to

Emitter Terminal

(E).

2. Connect

MT2

to

Collector Terminal

(C).

3. Connect

Trigger Terminal

to

MT2 Terminal

through a 10

resistor.

Note the following:

Due to the excessive amount of power that can be generated in

this test, only parts with an I

T(RMS)

rating of 8 A or less should be

tested on standard curve tracer. If testing devices above 8 A, a

Tektronix model 176 high-current module is required.

A Kelvin test fixture is required for this test. If a Kelvin fixture is

not used, an error in measurement of V

TM

will result due to volt-

age drop in fixture. If a Kelvin fixture is not available,

Figure AN1006.3 shows necessary information to wire a test

fixture with Kelvin connections.

To measure the V

TM (Forward and Reverse)

parameter:

1. Set

Terminal Selector

to

Emitter Grounded-Open Base

.

2. Set

Max Peak Volts

to

75 V

. (

80 V

on 370)

3. Set

Mode

to

Norm

.

4. Set

Horizontal

knob to

0.5 V/DIV

.

5. Set

Power Dissipation

to

220 watts

(

100 watts

on a 577).

6. Set

Vertical

knob to a sufficient setting to allow the viewing

of 1.4 times the I

T(RMS)

rating of the device I

T(peak)

on the CRT.

Procedure 9: V

TM(Forward)

To measure the V

TM (Forward)

parameter:

1. Set

Polarity

to (+).

2. Set

Left-Right Terminal Jack Selector

to correspond with

the location of the test fixture.

3. Increase

Variable Collector Supply Voltage

until current

reaches rated I

T(peak)

, which is 1.4 times the I

T(RMS)

rating of

the triac under test.

Note: Model 370 current is limited to 10 A.

WARNING: Limit test time to 15 seconds maximum.

4. To measure V

TM

, follow along horizontal scale to the point

where the trace crosses the I

T(peak)

value. This horizontal dis-

tance is the V

TM

value. (Figure AN1006.20)

Figure AN1006.20 V

TM (Forward)

= 1.1 V at I

PK

= 5.6 A

Procedure 10: V

TM(Reverse)

To measure the V

TM (Reverse)

parameter:

1. Set

Polarity

to (–).

2. Set

Left-Right Terminal Jack Selector

to correspond with

the location of the test fixture.

3. Increase

Variable Collector Supply Voltage

until current

reaches rated I

T(peak)

.

4. Measure V

TM(Reverse)

the same as in Procedure 8. (Read mea-

surements from upper right corner of screen).

50

A

10

V

PER

V

E

R

T

DIV

PER

H

O

R

I

Z

DIV

PER

S

T

E

P

()k

DIV

9m

PER

DIV

VBO

IBO

+VBO

+IBO

500

mV

PER

V

E

R

T

DIV

PER

H

O

R

I

Z

DIV

PER

S

T

E

P

IPK

VTM

1

A

()k

DIV

9m

PER

DIV

相關PDF資料 |

PDF描述 |

|---|---|

| AC12ESM | Thyristor Product Catalog |

| AC12FGML | Thyristor Product Catalog |

| AC12FSM | Thyristor Product Catalog |

| AC16BGM | Thyristor Product Catalog |

| AC16BSM | Thyristor Product Catalog |

相關代理商/技術參數(shù) |

參數(shù)描述 |

|---|---|

| AC12ESM | 制造商:TECCOR 制造商全稱:TECCOR 功能描述:Thyristor Product Catalog |

| AC12FGM | 制造商:NEC 制造商全稱:NEC 功能描述:12A MOLD TRIAC |

| AC12FGM(AZ) | 制造商:Renesas Electronics Corporation 功能描述: |

| AC12FGML | 制造商:TECCOR 制造商全稱:TECCOR 功能描述:Thyristor Product Catalog |

| AC12FSM | 制造商:TECCOR 制造商全稱:TECCOR 功能描述:Thyristor Product Catalog |

發(fā)布緊急采購,3分鐘左右您將得到回復。