- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄24691 > 05F7081 IC-TEMPERATURE TRANSDUCER PDF資料下載

參數(shù)資料

| 型號: | 05F7081 |

| 英文描述: | IC-TEMPERATURE TRANSDUCER |

| 中文描述: | 集成電路溫度傳感器 |

| 文件頁數(shù): | 9/12頁 |

| 文件大?。?/td> | 168K |

| 代理商: | 05F7081 |

AD590

–6–

REV. B

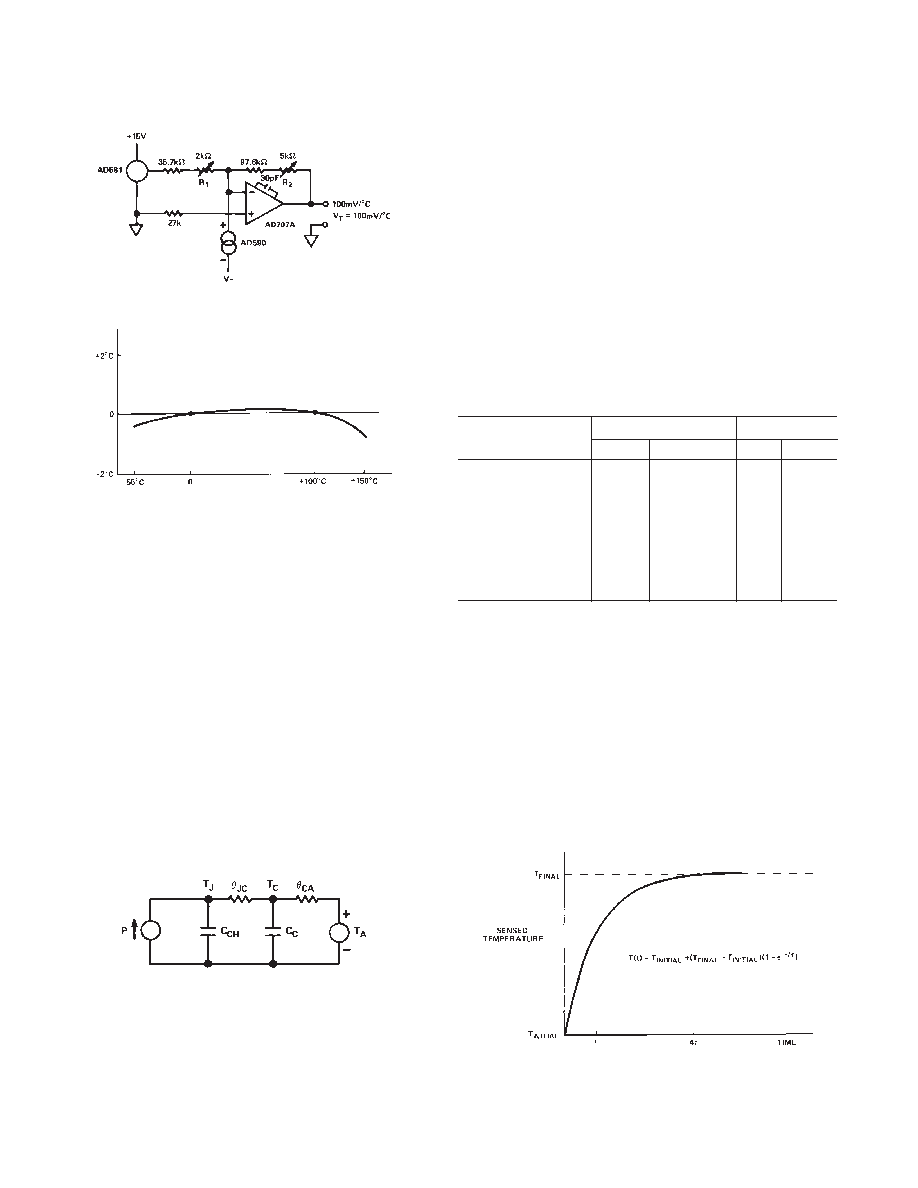

Figure 7A. Two Temperature Trim

Figure 7B. Typical Two-Trim Accuracy

VOLTAGE AND THERMAL ENVIRONMENT EFFECTS

The power supply rejection specifications show the maximum

expected change in output current versus input voltage changes.

The insensitivity of the output to input voltage allows the use of

unregulated supplies. It also means that hundreds of ohms of

resistance (such as a CMOS multiplexer) can be tolerated in

series with the device.

It is important to note that using a supply voltage other than 5 V

does not change the PTAT nature of the AD590. In other

words, this change is equivalent to a calibration error and can be

removed by the scale factor trim (see previous page).

The AD590 specifications are guaranteed for use in a low thermal

resistance environment with 5 V across the sensor. Large

changes in the thermal resistance of the sensor’s environment

will change the amount of self-heating and result in changes in

the output which are predictable but not necessarily desirable.

The thermal environment in which the AD590 is used deter-

mines two important characteristics: the effect of self heating

and the response of the sensor with time.

Figure 8. Thermal Circuit Model

Figure 8 is a model of the AD590 which demonstrates these

characteristics. As an example, for the TO-52 package,

θ

JC is

the thermal resistance between the chip and the case, about

26

°C/watt. θ

CA is the thermal resistance between the case and

the surroundings and is determined by the characteristics of the

thermal connection. Power source P represents the power

dissipated on the chip. The rise of the junction temperature, TJ,

above the ambient temperature TA is:

T

J T A = P (θ JC +θCA )

Equation 1

Table I gives the sum of

θ

JC and

θ

CA for several common

thermal media for both the “H” and “F” packages. The heatsink

used was a common clip-on. Using Equation 1, the temperature

rise of an AD590 “H” package in a stirred bath at +25

°C, when

driven with a 5 V supply, will be 0.06

°C. However, for the same

conditions in still air the temperature rise is 0.72

°C. For a given

supply voltage, the temperature rise varies with the current and

is PTAT. Therefore, if an application circuit is trimmed with

the sensor in the same thermal environment in which it will be

used, the scale factor trim compensates for this effect over the

entire temperature range.

Table I. Thermal Resistances

Medium

θ

JC +

θ

CA ( C/Watt)

τ (sec)(Note 3)

HF

H

F

Aluminum Block

30

10

0.6

0.1

Stirred Oil1

42

60

1.4

0.6

Moving Air

2

With Heat Sink

45

–

5.0

–

Without Heat Sink

115

190

13.5

10.0

Still Air

With Heat Sink

191

–

108

–

Without Heat Sink

480

650

60

30

1Note:

τ is dependent upon velocity of oil; average of several velocities listed

above.

2Air velocity

9 ft./sec.

3The time constant is defined as the time required to reach 63.2% of an

instantaneous temperature change.

The time response of the AD590 to a step change in tempera-

ture is determined by the thermal resistances and the thermal

capacities of the chip, CCH, and the case, CC. CCH is about

0.04 watt-sec/

°C for the AD590. C

C varies with the measured

medium since it includes anything that is in direct thermal

contact with the case. In most cases, the single time constant

exponential curve of Figure 9 is sufficient to describe the time

response, T (t). Table I shows the effective time constant,

τ, for

several media.

Figure 9. Time Response Curve

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| 934050050127 | 10.3 A, 60 V, 0.15 ohm, N-CHANNEL, Si, POWER, MOSFET, TO-220AB |

| 05F7082 | IC-TEMPERATURE TRANSDUCER |

| 05F7083 | IC-TEMPERATURE TRANSDUCER |

| 934054728118 | 10.3 A, 60 V, 0.15 ohm, N-CHANNEL, Si, POWER, MOSFET, TO-252AA |

| 05F7090 | IC-THERMOCOUPLE AMPLIFIER |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| 05FD101J03 | 制造商: 功能描述: 制造商:undefined 功能描述: |

| 05FD111J03 | 制造商: 功能描述: 制造商:undefined 功能描述: |

| 05FD161J03 | 制造商: 功能描述: 制造商:undefined 功能描述: |

| 05FD241J03 | 制造商: 功能描述: 制造商:undefined 功能描述: |

| 05FD271J03 | 制造商: 功能描述: 制造商:undefined 功能描述: |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。