- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄202514 > VKB41B2-44.736MHZ (CONNOR WINFIELD CORP) VCXO, CLOCK, 44.736 MHz, LVCMOS OUTPUT PDF資料下載

參數(shù)資料

| 型號(hào): | VKB41B2-44.736MHZ |

| 廠商: | CONNOR WINFIELD CORP |

| 元件分類: | VCXO, clock |

| 英文描述: | VCXO, CLOCK, 44.736 MHz, LVCMOS OUTPUT |

| 封裝: | HERMETICALLY SEALED, CERAMIC, LCC-6 |

| 文件頁(yè)數(shù): | 2/2頁(yè) |

| 文件大?。?/td> | 75K |

| 代理商: | VKB41B2-44.736MHZ |

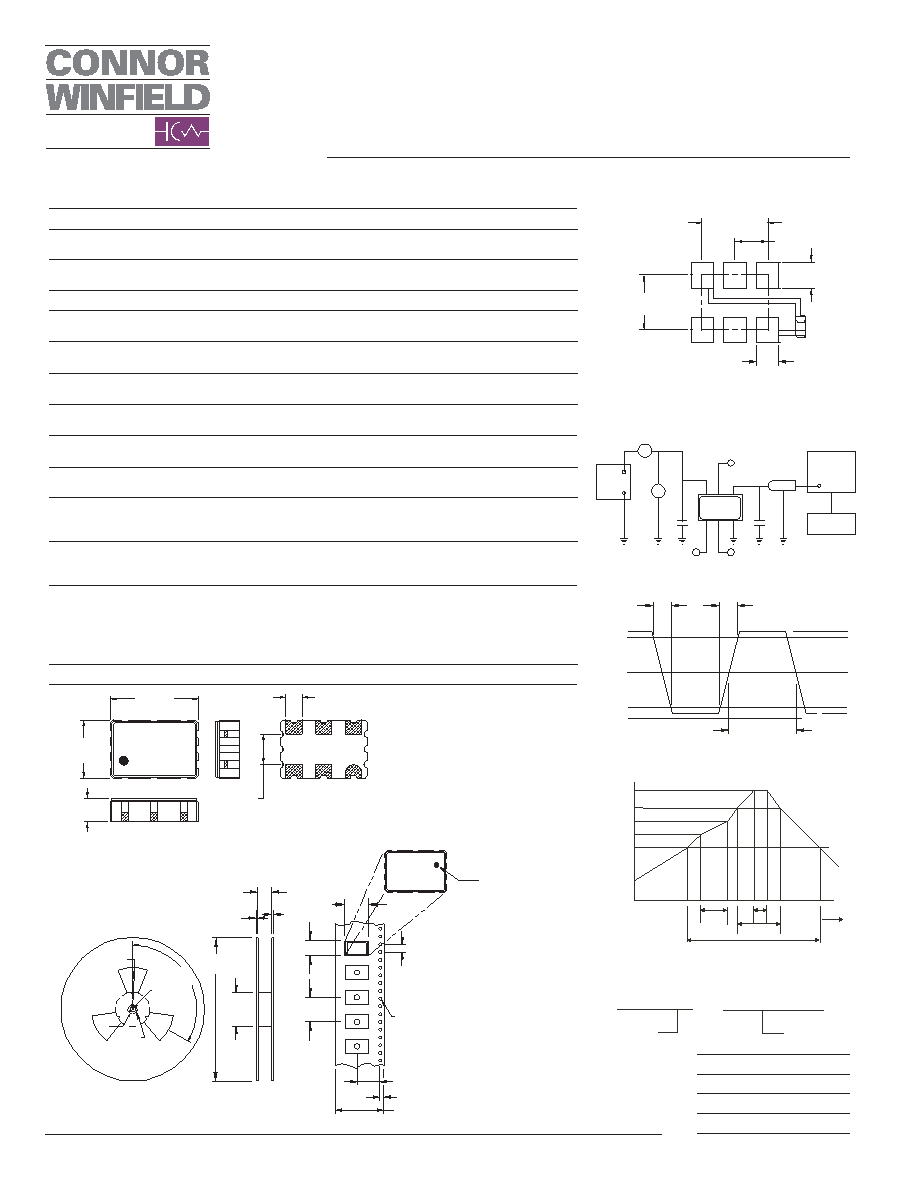

E/D

N/C

POWER

SUPPLY

A

V

OSC

INPUT for C/V

.01uf

OSCILLOSCOPE

FREQ

COUNTER

PROBE

CL

1 2

3

65

4

7.48 DIA

(190mm)

.69

(17.5mm)

.315

(8.0mm)

.039 R

(1.0mm)

.826 DIA

(21mm)

.511 DIA

(13mm)

9.84 DIA

(250mm)

MEETS EIA—481A and EIAJ—1009B

2,000 PCS/REEL

120

.08

(2.0mm)

3.15

(8.0mm)

.08

(2.0mm)

.157

(4.0mm)

.06 DIA

(1.5mm)

.31

(7.9mm)

.21

(5.4mm)

PIN 1

.295 (7.5mm)

.07 (1.75mm)

.63 (16.0mm)

Specifications subject to change without notice. All dimensions in inches. Copyright 1998 The Connor-Winfield Corporation

2111 Comprehensive Drive

Aurora, Illinois 60505

Phone: 630- 851- 4722

Fax: 630- 851- 5040

www.conwin.com

Package Characteristics

Package

Hermetically sealed, ceramic leadless package.

Bulletin

Vx351

Page

2 of 2

Revision

02

Date

06 April 2006

Soldering

General Conditions

260°C max x 10 sec max x 2 times max or

230°C max x 180 sec max x 1 time

Typical Operation Data

20 to 100 sec up to 215°C, 50 sec at 215°C,

(Vapor phase reflow)

then down to room temperature per 1 to 5°C / sec

Environmental Characteristics

Temperature Cycle

The specimen shall meet electrical characteristics after

tested 5 cycles of -55°C / 30 minutes and +125°C / 30 minutes

Hermetical

No bubbles appear in Flourinert (FC-43) at 125°C ±5°C for 5 minutes

Solvent Resistance

Marking will withstand immersion in

Isopropyl Alcohol or Trichloroethylene

Mechanical Characteristics

Free Drop

The specimen shall meet electrical characteristics after tested 3 times,

Free Drop testing on the hard wooden board from a height of 75 cm.

Vibration

The specimen shall meet electrical characteristics after tested

by the following conditions: 10-55Hz 1.5mm Amplitude,

55-2000 Hz 20 G's, 2 hours for each plane

Thermal Shock

After applied Thermal Shock of

245°C max x 10 sec max x 2 times, or 215°C max x 180 sec max,

the specimen shall meet electrical characteristics

Solderability

(EIAJ-RCX-0102/101 Condition 1a)

1) Flux: MIL-F-14256 (WW Rosin=25%, Isopropyl Alcohol = 75%)

2) Solder: QQ-S-571 (Sn = 63%, Pb = 37%)

3) Solder bath temperature: 235°C ±5°C

4) Depth of immersion: Up to electrical terminal

5) Immersing time: Within 2 sec ±0.5 sec into solder bath

After performing the above procedures, a newly soldered coverage shall be greater than 90%

Pin Function

1: Control Voltage (Vc)

2: Tri-state Enable /Disable

3: Ground

4: Output

5: N/C

6: +Supply (Vcc)

Suggested Pad Layout

Test Circuit

Output Waveform

SYMMETRY

"0" LEVEL

"1" LEVEL

TR

TF

10%

50%

90%

Ordering Information

VKB41B2 - 44.736 MHz

VCXO

SERIES

CENTER

FREQUENCY

Tape and Reel Dimensions

.295 MAX

(7.5mm)

.079 MAX

(2.0mm)

0.102

(2.6mm)

.197 MAX

(5.0mm)

0.055

(1.4mm)

Dimensional ±.02" (±0.5mm)

Tolerance:

±.008" (±0.2mm)

#1

#2

#3

#6

#5

#4

#1

#2

#3

#6

#5

#4

CW 0619

VKB41B2

44.736M

Dimensional

Tolerance:

±.02" (.508mm)

±.005" (.127mm)

Bypass capacitor, C–by, should be

ceramic capacitor

≥ .01uf.

0.165

(4.2mm)

VDD

GROUND

C–by

0.200

(5.08mm)

0.100

(2.54mm)

0.079

(2.0mm)

0.070

(1.8mm)

Solder Profile

120C

150C

180C

260C

0

220C

360 Sec. Max.

120 S

Max.

10 S

60 S

Max.

Time

Tem perature

260C

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| VKB51B2-51.84MHZ | VCXO, CLOCK, 51.84 MHz, HCMOS OUTPUT |

| VKB62B2-16.384MHZ | VCXO, CLOCK, 16.384 MHz, HCMOS OUTPUT |

| VKB62B2-FREQ-OUT27 | VCXO, CLOCK, 1 MHz - 45 MHz, HCMOS OUTPUT |

| VKP100MT315-(6)C | 3-OUTPUT 100 W DC-DC REG PWR SUPPLY MODULE |

| VKP60LT315 | 3-OUTPUT 60 W DC-DC REG PWR SUPPLY MODULE |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| VKBAA80C-00000-000 | 制造商:Carling Technologies 功能描述:V-SERIES ROCKER SWITCH - Bulk |

| VKBAA80H-CMH00-000 | 制造商:Carling Technologies 功能描述:V-SERIES ROCKER SWITCH - Bulk |

| VKBAAD0C-00000-000 | 制造商:Carling Technologies 功能描述:V-SERIES ROCKER SWITCH - Bulk |

| VKBAAJ0B-00000-000 | 制造商:Carling Technologies 功能描述:V-SERIES ROCKER SWITCH - Bulk |

| VKBAAP0C-00000-000 | 制造商:Carling Technologies 功能描述:V-SERIES ROCKER SWITCH - Bulk |

發(fā)布緊急采購(gòu),3分鐘左右您將得到回復(fù)。