- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄359316 > V251NA34 (Littelfuse, Inc.) Varistor Products - High Energy Industrial Square Disc PDF資料下載

參數(shù)資料

| 型號: | V251NA34 |

| 廠商: | Littelfuse, Inc. |

| 元件分類: | 壓敏電阻 |

| 英文描述: | Varistor Products - High Energy Industrial Square Disc |

| 中文描述: | 壓敏電阻器產(chǎn)品-高能工業(yè)廣場光盤 |

| 文件頁數(shù): | 5/5頁 |

| 文件大小: | 89K |

| 代理商: | V251NA34 |

126

www.littelfuse.com

Varistor Products

NA Varistor Series

Passivation Layer

The standard NA Series is supplied with passivation layer around the

outside perimeter of the disc forming an electrical insulator as detailed in

the dimensional drawing.

Encapsulated Recommendations

After lead attachment, the disc/lead assembly may be coated or

encapsulated in a package to provide electrical insulation and isolation

from environmental contamination as required by the application.

Coating/Filler materials for containers may include silicones,

polyurethanes, and some epoxy resins.Two examples of acceptable

polyurethanes are Dexter Hysol (US7013, parts A and B) and Rhenatech

(resin 4714, hardener 4900), or their equivalents. Materials containing

halogens, sulfides, or alkalines are not recommended.

Electrode Metallization

The NA Series is supplied with a sintered silver metallization for the

electrode finish.The silver metallization is typically used for solder reflow

lead attach operations (I-R, Vapour-Phase).

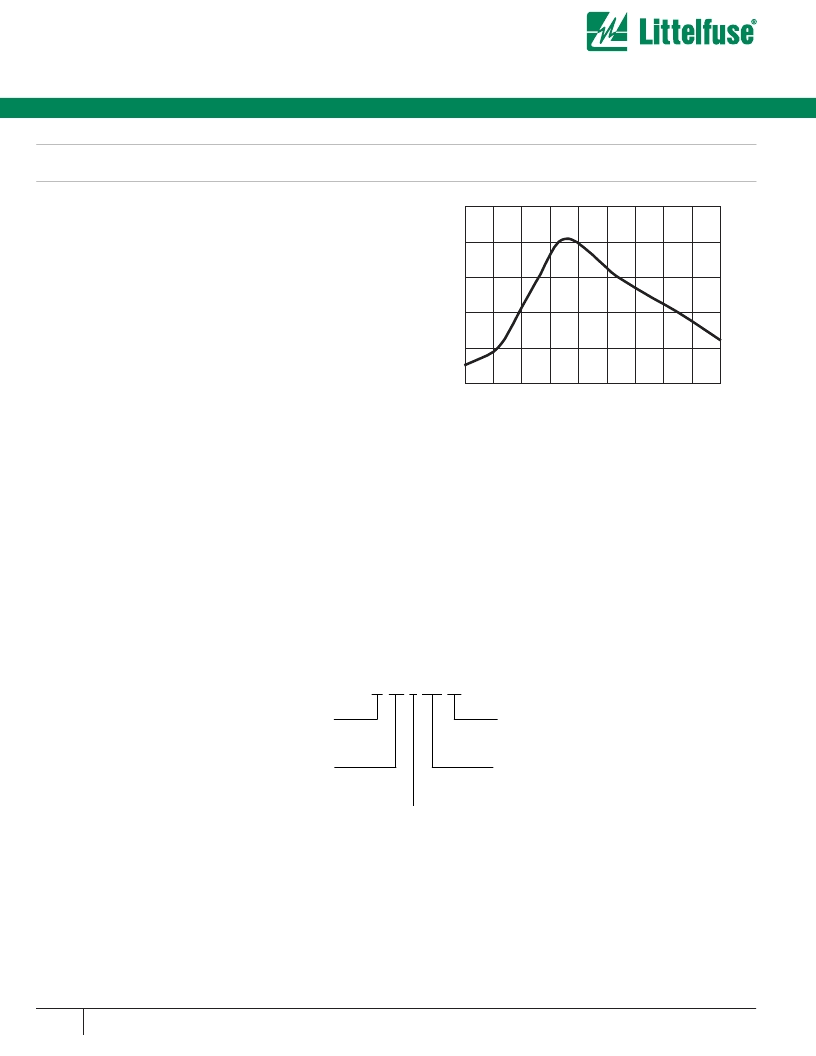

The recommended temperature profile of a belt-fed convection oven is

shown in Figure 6.

Stacking and Contact Pressure

Recommendations

When applications require the stacking of Littelfuse NA discs or when

electrical connection is made by pressure contacts, the minimum pres-

sure applied to the disc electrode surface should be 2.2kGs (5 pounds).

The maximum recommended pressure applied to the disc electrode is

16N/CM

2

(23LBs/IN

2

).

Packaging and Shipping

The NA Series is supplied in bulk for shipment. Discs are packaged in

compartmentalized cartons to protect from scratching or edge-chipping

during shipment.

T

o

C

250

200

150

100

50

0

0

100

200

300

400

TIME (SEC)

500

600

700

800

900

FIGURE 6. TYPICAL BELT OVEN TEMPERATURE PROFILE

Ordering Information

VARISTOR DESIGNATOR

MAX AC

RMS

WORKING VOLTAGE

(FIRST SIGNIFICANT DIGITS) V

M(AC)

DISC SIZE (mm)

SERIES DESIGNATOR

V

M(AC)

VOLTAGE DECADE MULTIPLIER

V 25 1 NA 34

High Energy Industrial Square Disc

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| V26L8060AA | color TFT LCD module |

| V26MLA0805 | POWER QUICC |

| V26MLA0805L | Multilayer Transient Voltage Surge Suppressors |

| V271CA32 | Varistor Products - High Energy Industrial Disc |

| V27MA1A | Varistor Products - Axial Lead |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| V251S001-1ZZ00-000 | 制造商:Carling Technologies 功能描述:V-SERIES ROCKER SWITCH - Bulk |

| V251S001-4ZZ00-000 | 制造商:Carling Technologies 功能描述:V-SERIES ROCKER SWITCH - Bulk |

| V251S001-4ZZM7-100 | 制造商:Carling Technologies 功能描述:V-SERIES ROCKER SWITCH - Bulk |

| V251S001-4ZZM7-100-XSU1 | 制造商:Carling Technologies 功能描述:V-SERIES ROCKER SWITCH - Bulk |

| V251S001-4ZZXX-300-XSU1 | 制造商:Carling Technologies 功能描述:V-SERIES ROCKER SWITCH - Bulk |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。