- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄361611 > V048F480M006 (Vicor Corporation) VI Chip - VTM Voltage Transformation Module PDF資料下載

參數(shù)資料

| 型號: | V048F480M006 |

| 廠商: | Vicor Corporation |

| 元件分類: | DC/DC變換器 |

| 英文描述: | VI Chip - VTM Voltage Transformation Module |

| 中文描述: | 六芯片- VTM電壓轉(zhuǎn)換模塊 |

| 文件頁數(shù): | 10/15頁 |

| 文件大小: | 491K |

| 代理商: | V048F480M006 |

vicorpower.com

800-735-6200

VI Chip Voltage Transformation Module

V048K480T006

Rev. 1.0

Page 10 of 15

VI Chip Voltage Transformation Module

PRELIMINARY

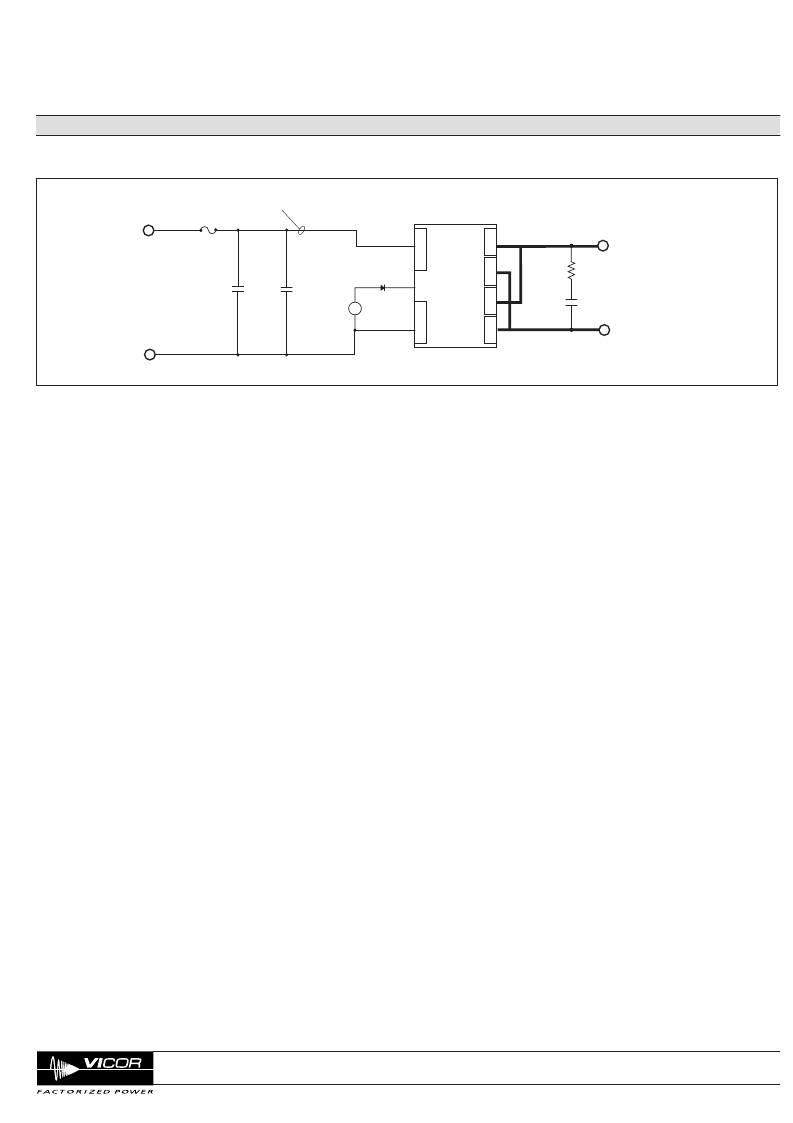

Figure 16

—VTM test circuit

Application Note

Parallel Operation

In applications requiring higher current or redundancy, VTMs can be

operated in parallel without adding control circuitry or signal lines. To

maximize current sharing accuracy, it is imperative that the source and

load impedance on each VTM in a parallel array be equal. If VTMs are

being fed by an upstream PRM, the VC nodes of all VTMs must be

connected to the PRM VC.

To achieve matched impedances, dedicated power planes within the PC

board should be used for the output and output return paths to the

array of paralleled VTMs. This technique is preferable to using traces of

varying size and length.

The VTM power train and control architecture allow bi-directional

power transfer when the VTM is operating within its specified ranges.

Bi-directional power processing improves transient response in the

event of an output load dump. The VTM may operate in reverse,

returning output power back to the input source. It does so efficiently.

Thermal Management

The high efficiency of the VTM results in low power dissipation

minimizing temperature rise, even at full output current. The heat

generated within the internal semiconductor junctions is coupled

through very low thermal resistances, R

θ

JC

and R

θ

JB

(see Figure 17),

to the PC board allowing flexible thermal management.

CASE 1 Convection via optional Heat Sink to air.

In an environment with forced convection over the surface of a PCB

with 0.4" of headroom, a VTM with a 0.25" heat sink offers a simple

thermal management option. The total Junction to Ambient thermal

resistance of a surface mounted V048K480T006 with a heat sink

attached is 4.8 oC/W in 300 LFM airflow, (see Figure 18).

At 48 Vout and full rated current (6.3A), the VTM dissipates

approximately 11 W per Figure 4. This results in a temperature rise of

approximately 53 oC, allowing operation in an air temperature of

72 oC without exceeding the 125 oC max junction temperature.

CASE 2 Conduction via the PC board to air

The low Junction to BGA thermal resistance allows the use

of the PC board as a means of removing heat from the VTM.

Convection from the PC board to ambient, or conduction to a cold

plate, enable flexible thermal management options.

With a VTM mounted on a 2.0 in

2

area of a multi-layer PC board with

appropriate power planes resulting in 8 oz of effective copper weight,

the Junction-to-BGA thermal resistance, R

θ

JA

, is 6.5 oC/W in 300 LFM

of air. With a maximum junction temperature of 125 oC and 11 W of

dissipation at full current of 6.3 A, the resulting temperature rise of

72 oC allows the VTM to operate at full rated current up to a 53 oC

ambient temperature. See thermal resistances on Page 9 for additional

details on this thermal management option.

Adding low-profile heat sinks to the PC board can lower the thermal

resistance of the PC board surrounding the VTM. Additional cooling

may be added by coupling a cold plate to the PC board with low

thermal resistance stand offs.

CASE 3 Combined direct convection to the air and conduction to the

PC board.

A combination of cooling techniques that utilize the power planes and

dissipation to the air will also reduce the total thermal impedance. This

is the most effective cooling method. To estimate the total effect of the

combination, treat each cooling branch as one leg of a parallel resistor

network.

F1

Load

+

–

Input reflected ripple

measurement point

C2

0.47

F

ceramic

+

14 V

-In

PC

VC

TM

+In

-Out

+Out

VTM

+Out

-Out

K

Ro

Notes:

C3 should be placed close

to the load

R3 may be ESR of C3 or a

seperate damping resistor.

C3

9.4 μF

R3

5 m

C1

47 μF

Al electrolytic

10A

Fuse

CONFIGURATION OPTIONS

(continued)

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| V048G015T80 | VI Chip - VTM Voltage Transformation Module |

| V048K015T80 | VI Chip - VTM Voltage Transformation Module |

| V048K015T090 | VI Chip - PRM-AL Pre-regulator Module |

| V048K015T100 | VI Chip - PRM-AL Pre-regulator Module |

| V048L015T80 | VI Chip - VTM Voltage Transformation Module |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| V048F480M009 | 制造商:POWERBOX 制造商全稱:Powerbox 功能描述:300W DC/DC VOLTAGE TRANSFORMATION MODULE PRELIMINARY |

| V048F480M012 | 制造商:POWERBOX 制造商全稱:Powerbox 功能描述:300W DC/DC VOLTAGE TRANSFORMATION MODULE PRELIMINARY |

| V048F480M015 | 制造商:POWERBOX 制造商全稱:Powerbox 功能描述:300W DC/DC VOLTAGE TRANSFORMATION MODULE PRELIMINARY |

| V048F480M025 | 制造商:POWERBOX 制造商全稱:Powerbox 功能描述:300W DC/DC VOLTAGE TRANSFORMATION MODULE PRELIMINARY |

| V048F480M030 | 制造商:POWERBOX 制造商全稱:Powerbox 功能描述:300W DC/DC VOLTAGE TRANSFORMATION MODULE PRELIMINARY |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。