- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄378749 > UPD784224YGC (NEC Corp.) 16/8-BIT SINGLE-CHIP MICROCONTROLLERS PDF資料下載

參數(shù)資料

| 型號: | UPD784224YGC |

| 廠商: | NEC Corp. |

| 英文描述: | 16/8-BIT SINGLE-CHIP MICROCONTROLLERS |

| 中文描述: | 16/8-BIT單晶片微控制器 |

| 文件頁數(shù): | 84/92頁 |

| 文件大小: | 687K |

| 代理商: | UPD784224YGC |

第1頁第2頁第3頁第4頁第5頁第6頁第7頁第8頁第9頁第10頁第11頁第12頁第13頁第14頁第15頁第16頁第17頁第18頁第19頁第20頁第21頁第22頁第23頁第24頁第25頁第26頁第27頁第28頁第29頁第30頁第31頁第32頁第33頁第34頁第35頁第36頁第37頁第38頁第39頁第40頁第41頁第42頁第43頁第44頁第45頁第46頁第47頁第48頁第49頁第50頁第51頁第52頁第53頁第54頁第55頁第56頁第57頁第58頁第59頁第60頁第61頁第62頁第63頁第64頁第65頁第66頁第67頁第68頁第69頁第70頁第71頁第72頁第73頁第74頁第75頁第76頁第77頁第78頁第79頁第80頁第81頁第82頁第83頁當前第84頁第85頁第86頁第87頁第88頁第89頁第90頁第91頁第92頁

84

μ

PD784224, 784225, 784224Y, 784225Y

Data Sheet U12376EJ1V0DS00

16. RECOMMENDED SOLDERING CONDITIONS

The

μ

PD784225 should be soldered and mounted under the following recommended conditions.

For the details of the recommended soldering conditions, refer to the document

Semiconductor Device

Mounting Technology Manual (C10535E)

.

For soldering methods and conditions other than those recommended below, contact your NEC sales representative.

Caution

Soldering conditions for the

μ

PD784224GC-

×××

-8BT,

μ

PD784225YGC-

×××

-8BT, and

μ

PD784225YGK-

×××

-9EU are undetermined because these products are under development.

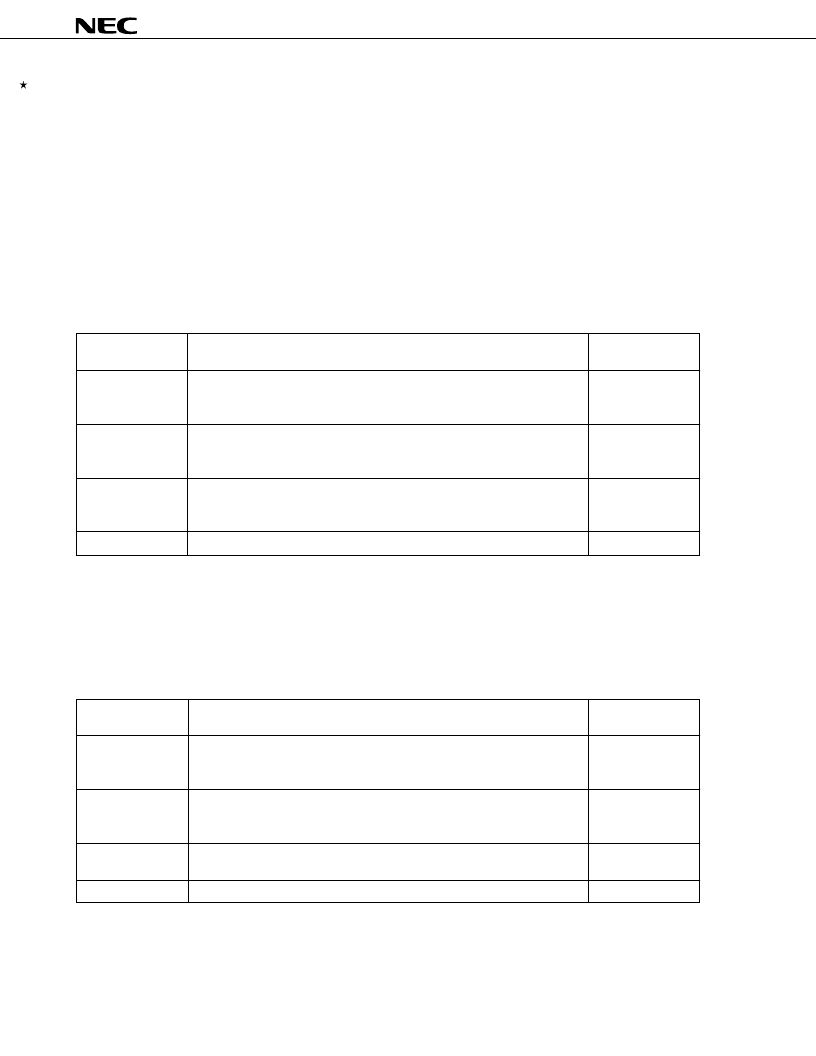

Table 16-1. Soldering Conditions for Surface Mount Type

(1)

μ

PD784225GC-

×××

-8BT: 80-pin plastic QFP (14

×

14 mm)

Soldering Method

Soldering Conditions

Recommended

Condition Symbol

Infrared reflow

Package peak temperature: 235

°

C, Time: 30 seconds max. (at 210

°

C or

higher), Count: Two times or less, Exposure limit: 7 days

Note

(after that,

prebake at 125

°

C for 20 hours)

IR35-00-2

VPS

Package peak temperature: 215

°

C, Time: 40 seconds max. (at 200

°

C or

higher), Count: Two times or less, Exposure limit: 7 days

Note

(after that,

prebake at 125

°

C for 20 hours)

VP15-00-2

Wave soldering

Solder bath temperature: 260

°

C max., Time: 10 seconds max., Count: Once,

Preheating temperature: 120

°

C max. (package surface temperature)

Exposure limit: 7 days

Note

(after that, prebake at 125

°

C for 20 hours)

—

Partial heating

Pin temperature: 300

°

C max., Time: 3 seconds max. (per pin row)

—

Note

After opening the dry pack, store it at 25

°

C or less and 65% RH or less for the allowable storage period.

Caution

Do not use different soldering methods together (except for partial heating).

(2)

μ

PD784224GK-

×××

-9EU: 80-pin plastic TQFP (fine pitch) (14

×

20 mm)

μ

PD784225GK-

×××

-9EU: 80-pin plastic TQFP (fine pitch) (14

×

20 mm)

Soldering Method

Soldering Conditions

Recommended

Condition Symbol

Infrared reflow

Package peak temperature: 235

°

C, Time: 30 seconds max. (at 210

°

C or

higher), Count: Two times or less, Exposure limit: 7 days

Note

(after that,

prebake at 125

°

C for 20 hours)

IR35-103-2

VPS

Package peak temperature: 215

°

C, Time: 40 seconds max. (at 200

°

C or

higher), Count: Two times or less, Exposure limit: 7 days

Note

(after that,

prebake at 125

°

C for 20 hours)

VP15-103-2

Wave soldering

Solder bath temperature: 260

°

C max., Time: 10 seconds max., Count: Once,

Preheating temperature: 120

°

C max. (package surface temperature)

—

Partial heating

Pin temperature: 300

°

C max., Time: 3 seconds max. (per pin row)

—

Caution

Do not use different soldering methods together (except for partial heating).

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| UPD784225YGC | 16/8-BIT SINGLE-CHIP MICROCONTROLLERS |

| UPD784225YGK | 16/8-BIT SINGLE-CHIP MICROCONTROLLERS |

| UPD784225GC | 16/8-BIT SINGLE-CHIP MICROCONTROLLERS |

| UPD784225GK | 16/8-BIT SINGLE-CHIP MICROCONTROLLERS |

| UPD784224 | 16/8-BIT SINGLE-CHIP MICROCONTROLLERS |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| UPD784935AGF-113-3BA | 制造商:NEC Electronics Corporation 功能描述: |

| UPD784938AGF-188-3BA | 制造商:NEC Electronics Corporation 功能描述: |

| UPD789104AMC(A)-968-5A4-E2 | 制造商:Renesas Electronics Corporation 功能描述: |

| UPD789104AMC-671-5A4-E1 | 制造商:Renesas Electronics Corporation 功能描述: |

| UPD789104AMC-672-5A4-E1 | 制造商:Renesas Electronics Corporation 功能描述: |

發(fā)布緊急采購,3分鐘左右您將得到回復。