- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄300050 > ULQ-2/25-D24P (CD TECHNOLOGIES INC) 1-OUTPUT DC-DC REG PWR SUPPLY MODULE PDF資料下載

參數(shù)資料

| 型號: | ULQ-2/25-D24P |

| 廠商: | CD TECHNOLOGIES INC |

| 元件分類: | 電源模塊 |

| 英文描述: | 1-OUTPUT DC-DC REG PWR SUPPLY MODULE |

| 封裝: | 1.450 X 2.300 INCH, 0.350 INCH HEIGHT, QUARTER BRICK PACKAGE-8 |

| 文件頁數(shù): | 12/16頁 |

| 文件大?。?/td> | 566K |

| 代理商: | ULQ-2/25-D24P |

ULQ Models

8 - 2 5 A M P , S I N G L E O U T P U T C O N V E R T E R S

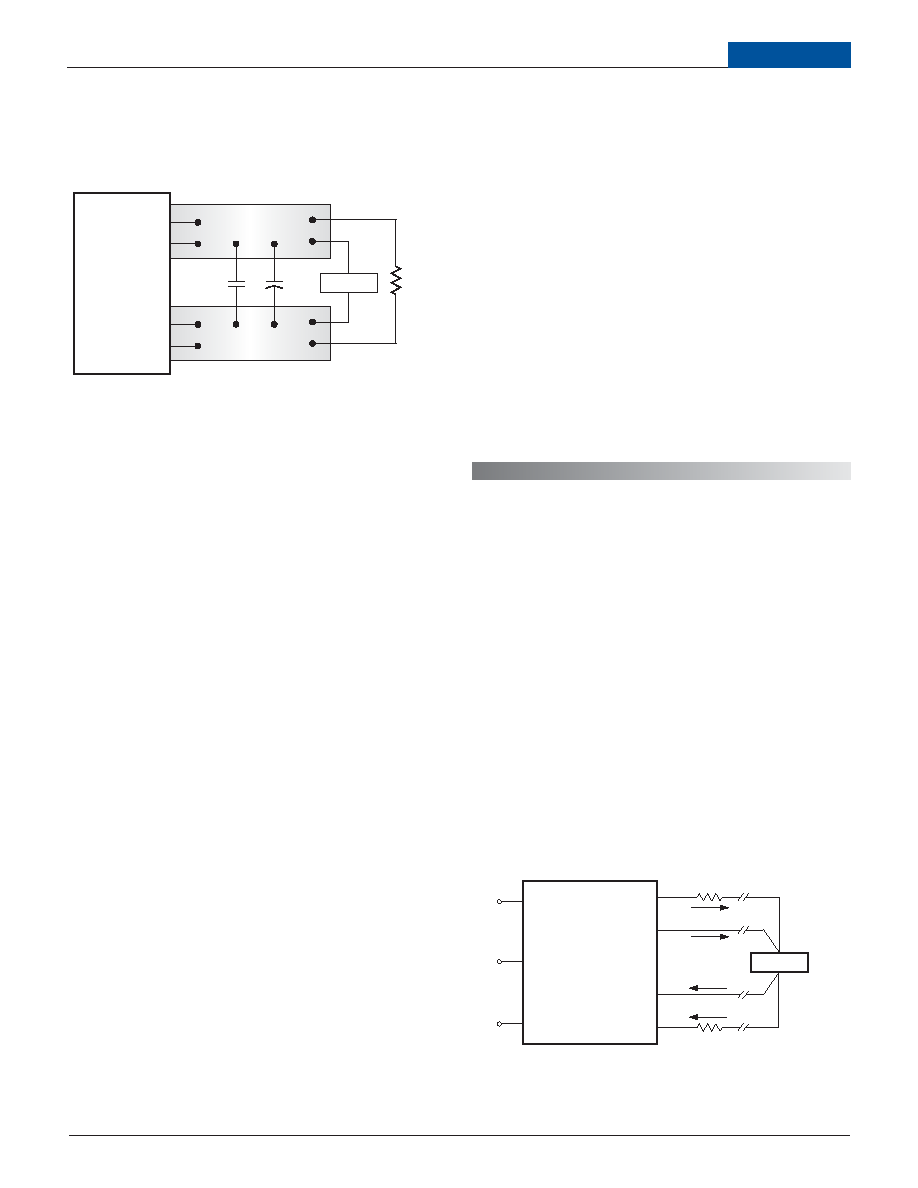

In Figure 3, the two copper strips simulate real-world pcb impedances

between the power supply and its load. In order to minimize measurement

errors, scope measurements should be made using BNC connectors, or the

probe ground should be less than inch and soldered directly to the xture.

C1

C1 = 0.1F CERAMIC

C2 = 10F TANTALUM

LOAD 2-3 INCHES (51-76mm) FROM MODULE

C2

RLOAD

7

8

COPPER STRIP

4

COPPER STRIP

SCOPE

+OUTPUT

–OUTPUT

+SENSE

–SENSE

Figure 3. Measuring Output Ripple/Noise (PARD)

Floating Outputs

Since these are isolated DC/DC converters, their outputs are "oating" with

respect to their input. Designers will normally use the –Output (pin 4) as the

ground/return of the load circuit.You can however, use the +Output (pin 8) as

ground/return to effectively reverse the output polarity.

Minimum Output Loading Requirements

ULQ converters employ a synchronous-rectier design topology and all

models regulate within spec and are stable under no-load to full load condi-

tions. Operation under no-load conditions however might slightly increase the

output ripple and noise.

Thermal Shutdown

The ULQ converters are equipped with thermal-shutdown circuitry. If envi-

ronmental conditions cause the temperature of the DC/DC converter to

rise above the designed operating temperature, a precision temperature

sensor will power down the unit. When the internal temperature decreases

below the threshold of the temperature sensor, the unit will self start. See

Performance/Functional Specications.

Output Overvoltage Protection

The ULQ output voltage is monitored for an overvoltage condition using a

comparator. The signal is optically coupled to the primary side and if the

output voltage rises to a level which could be damaging to the load, the sens-

ing circuitry will power down the PWM controller causing the output voltage

to decrease. Following a time-out period the PWM will restart, causing the

output voltage to ramp to its appropriate value. If the fault condition persists,

and the output voltage again climbs to excessive levels, the overvoltage

circuitry will initiate another shutdown cycle. This on/off cycling is referred to

as "hiccup" mode.

Current Limiting

As soon as the output current increases to approximately 130% of its rated

value, the DC/DC converter will go into a current-limiting mode. In this condi-

tion, the output voltage will decrease proportionately with increases in output

current, thereby maintaining somewhat constant power dissipation. This is

commonly referred to as power limiting. Current limit inception is dened

as the point at which the full-power output voltage falls below the specied

tolerance. See Performance/Functional Specications. If the load current,

being drawn from the converter, is signicant enough, the unit will go into a

short circuit condition as described below.

Short Circuit Condition

When a converter is in current-limit mode, the output voltage will drop as

the output current demand increases. If the output voltage drops too low, the

magnetically coupled voltage used to develop primary side voltages will also

drop, thereby shutting down the PWM controller. Following a time-out period,

the PWM will restart causing the output voltage to begin ramping to their

appropriate value. If the short-circuit condition persists, another shutdown

cycle will be initiated. This on/off cycling is referred to as "hiccup" mode.

The hiccup cycling reduces the average output current, thereby preventing

internal temperatures from rising to excessive levels. The ULQ Series is

capable of enduring an indenite short circuit output condition.

5

LOAD

+OUTPUT

–INPUT

Sense Current

Contact and PCB resistance

losses due to IR drops

Contact and PCB resistance

losses due to IR drops

Sense Return

+INPUT

ON/OFF

CONTROL

TRIM

+SENSE

–OUTPUT

–SENSE

4

5

1

3

6

8

IOUT Return

IOUT

7

2

Remote Sense

Note: The Sense and VOUT lines are internally connected through low-value

resistors. Nevertheless, if the sense function is not used for remote regulation

the user should connect the +Sense to +VOUT and -Sense to –VOUT at the

DC/DC converter pins.

ULQ series converters employ a sense feature to provide point of use regula-

tion, thereby overcoming moderate IR drops in pcb conductors or cabling.

The remote sense lines carry very little current and therefore require minimal

cross-sectional-area conductors. The sense lines, which are capacitively

coupled to their respective output lines, are used by the feedback control-loop

to regulate the output. As such, they are not low impedance points and must

be treated with care in layouts and cabling. Sense lines on a pcb should be

run adjacent to dc signals, preferably ground. In cables and discrete wiring

applications, twisted pair or other techniques should be implemented.

ULQ series converters will compensate for drops between the output voltage

at the DC/DC and the sense voltage at the DC/DC provided that:

[VOUT(+) –VOUT(–)] – [Sense(+) –Sense (–)]

≤ 10% VOUT

Figure 4. Remote Sense Circuit Conguration

F E A T U R E S A N D O P T I O N S

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| ULQ-3.3/20-D24NL1 | 1-OUTPUT DC-DC REG PWR SUPPLY MODULE |

| UM-LR-PC | CONNECTOR ACCESSORY |

| UM-PR-PC | CONNECTOR ACCESSORY |

| UM-QA-JJ | CONNECTOR ACCESSORY |

| UM-QLP-1.5-6 | CONNECTOR ACCESSORY |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| ULQ2436M | 制造商:ALLEGRO 制造商全稱:Allegro MicroSystems 功能描述:COUNTDOWN POWER TIMER |

| ULQ2460A | 制造商:ALLEGRO 制造商全稱:Allegro MicroSystems 功能描述:ELECTRONIC IGNITION TIMING |

| ULQ2460C | 制造商:ALLEGRO 制造商全稱:Allegro MicroSystems 功能描述:ELECTRONIC IGNITION TIMING |

| ULQ2460LW | 制造商:Allegro MicroSystems LLC 功能描述: |

| ULQ2470L | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:BUS DRIVER / RECEIVER |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。