- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄199513 > TV26RS (AMPHENOL CORP) STAINLESS STEEL, FEMALE; MALE, MIL SERIES CONNECTOR, CRIMP, PLUG PDF資料下載

參數(shù)資料

| 型號: | TV26RS |

| 廠商: | AMPHENOL CORP |

| 元件分類: | MIL系列連接器 |

| 英文描述: | STAINLESS STEEL, FEMALE; MALE, MIL SERIES CONNECTOR, CRIMP, PLUG |

| 文件頁數(shù): | 1/1頁 |

| 文件大小: | 36K |

| 代理商: | TV26RS |

19

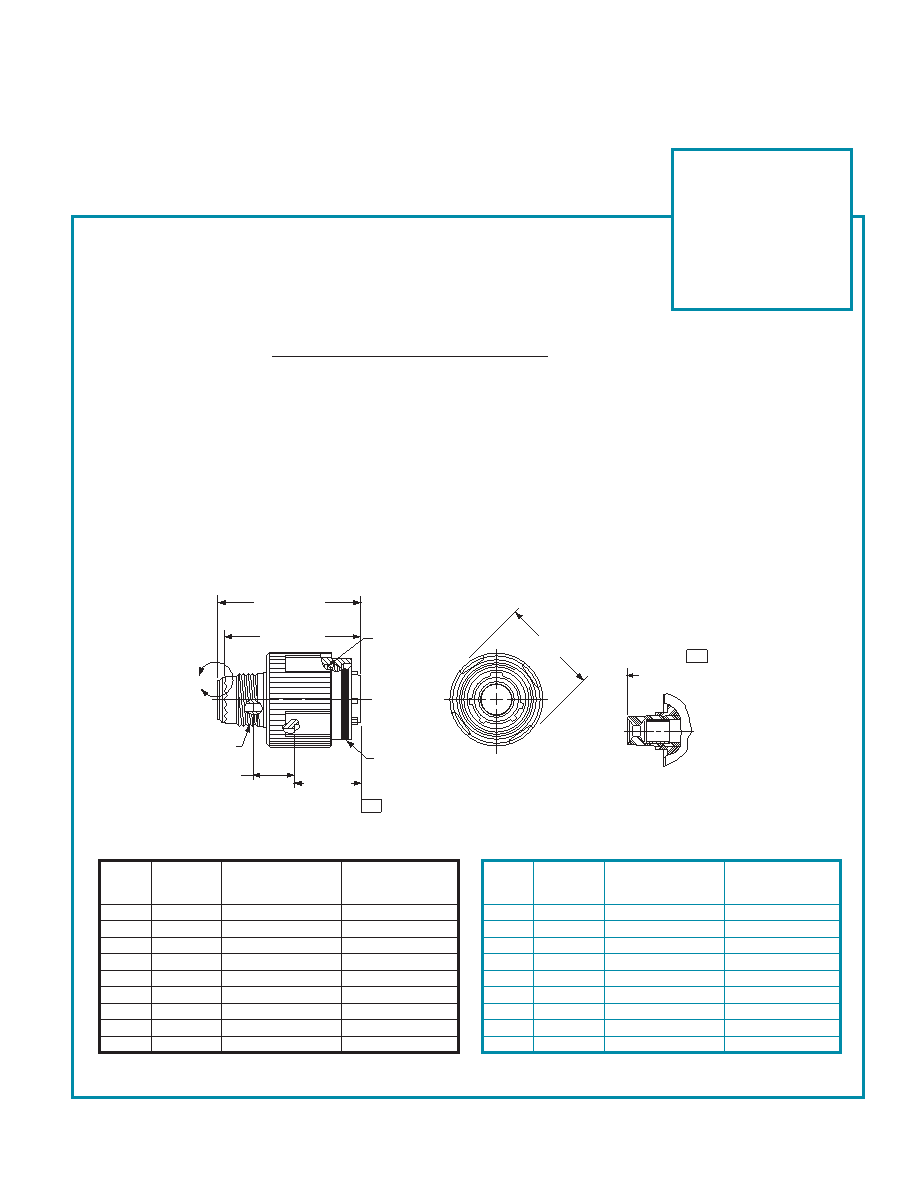

TV26/MTV26 – crimp, metal

CLUTCH-LOK straight plug for high vibration

and harsh environment applications

The latest in MIL-DTL-38999, Series III Connector Technology is the CLUTCH-LOK. Designed

for high vibration and harsh environments such as aircraft gas turbine engines, it is also an

ideal choice for demanding applications such as aircraft, space and military ground vehicles.

The unique clutch design of the Amphenol CLUTCH-LOK means that you don’t have to

compromise the need for quick, smooth mating of plugs and receptacles in order to get

increased uncoupling torque.

The CLUTCH-LOK has proven to not only remain mated and pass all the Series III specifica-

tion requirements - it also has proven to actually tighten itself under vibration. This is a

powerful advantage over the traditionally high vibration application connectors. The CLUTCH-

LOK is also a tremendous advantage in inaccessible, hard to reach areas where mating

torque is difficult to apply and complete coupling is not verifiable by inspection.

CLUTCH-LOK features and benefits:

High degree of differential torque

Infinite free coupling and positive metal-to-metal bottoming with each mating

No settling back to the next ratchet tooth

Available with stainless steel shells and Class K firewall inserts

All the advantages of MIL-DTL-38999 Series III including EMI/RFI shielding, electrolytic erosion

resistance and contact protection with recessed pins

Enhanced connector performance at affordable prices

Completely intermateable with all existing MIL-DTL-38999 Series III connectors

Fully QPL’d

Part number reference.

See how to order, pages 43, 44

to complete.

TV26RKXXXXX

TV26RSXXXXX

For parts with MS Stamping

use MTV26( ) part number as

follow:

MTV26RKXXXXX

MTV26RSXXXXX

MS

B Thread

Q

Shell

Shell Size

0.1P-0.3L-TS-2B

Dia.

Size

Code

(Plated)

Max.

9

A

.6250

.858

11

B

.7500

.984

13

C

.8750

1.157

15

D

1.0000

1.280

17

E

1.1875

1.406

19

F

1.2500

1.516

21

G

1.3750

1.642

23

H

1.5000

1.768

25

J

1.6250

1.890

Blue band indicates rear release contact retention system

All dimensions for reference only.

MS

V

Shell

Shell Size

Q

Thread

Size

Code

Max.

Metric

9

A

21.8

M12X1-6g

11

B

25.0

M15X1-6g

13

C

29.4

M18X1-6g

15

D

32.5

M22X1-6g

17

E

35.7

M25X1-6g

19

F

38.5

M28X1-6g

21

G

41.7

M31X1-6g

23

H

44.9

M34X1-6g

25

J

48.0

M37X1-6g

Inches

Millimeters

1.234 MAX

31.34 MAX

1.220 MAX

31.00 MAX

B THREAD

D

V THREAD

.359 MAX

9.12 MAX

.591 +.003

–.000

15.01 +.08

–.00

BLUE BAND

Q

1.656 MAX

42.06 MAX

VIEW D

FOR SIZE 8 COAXIAL ONLY,

RELATIVE TO –A–

–A–

相關PDF資料 |

PDF描述 |

|---|---|

| TV79BAGCACAC25.000 | TCVCXO, SINE OUTPUT, 25 MHz |

| TV79BAGBDCBDFREQ | TCVCXO, SINE OUTPUT, 0.625 MHz - 52 MHz |

| TV79BAGCACEC25.000 | TCVCXO, SINE OUTPUT, 25 MHz |

| TV79BAGCBBCD25.000 | TCVCXO, CLIPPED SINE OUTPUT, 25 MHz |

| TV79BAGCBBEDFREQ | TCVCXO, CLIPPED SINE OUTPUT, 0.625 MHz - 52 MHz |

相關代理商/技術參數(shù) |

參數(shù)描述 |

|---|---|

| TV270VC/A | 制造商:Promise Technologies 功能描述:VTRAK E-CLASS SINGLE-CONTROLLER (4) 1TB SATA HDDS - Bulk |

| TV2713D-IR | 制造商:Hikvision USA 功能描述:Lens, IR Varifocal 2.7~13mmDc Auto IRis, 1/3In Format 制造商:HIKVISION 功能描述:LENS, IR VARIFOCAL 2.7-13MM DC AUTO IRIS, 1/3IN FORMAT |

| TV272VC/A | 制造商:Promise Technologies 功能描述:VTRAK E-CLASS 3U/16-BAY DUAL-CONTROLLER (8) 1TB SATA HDDS - Bulk |

| TV274VC/A | 制造商:Promise Technologies 功能描述:VTRAK J-CLASS 3U/16-BAY DUAL-CONTROLLER (16) 1TB SATA HDDS - Bulk |

| TV276ZM/A | 制造商:Promise Technologies 功能描述:APPLE VTRAK E-CLASS SUBSYSTEM SERVICE PARTS KIT - Bulk |

發(fā)布緊急采購,3分鐘左右您將得到回復。