- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄358395 > SKKH132/22E (SEMIKRON INTERNATIONAL) 220 A, 2200 V, SCR PDF資料下載

參數(shù)資料

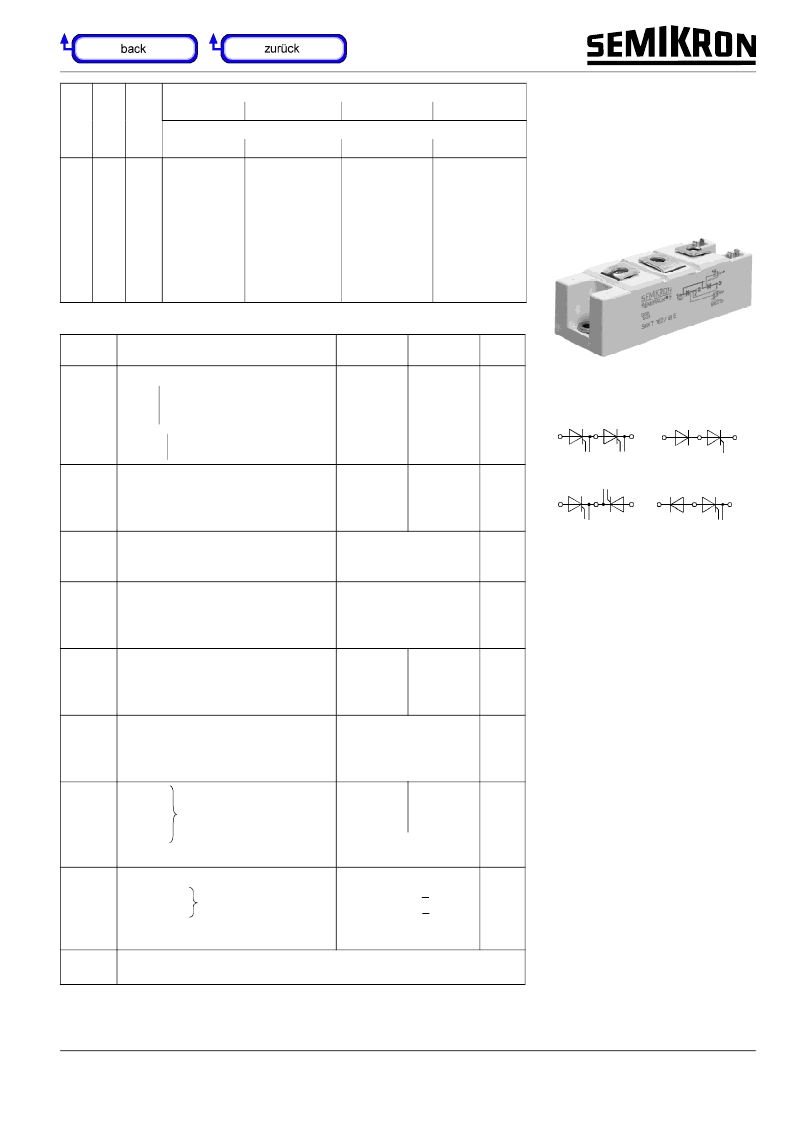

| 型號(hào): | SKKH132/22E |

| 廠商: | SEMIKRON INTERNATIONAL |

| 元件分類: | 晶閘管 |

| 英文描述: | 220 A, 2200 V, SCR |

| 封裝: | CERAMIC, CASE A22, SEMIPACK-5 |

| 文件頁數(shù): | 1/7頁 |

| 文件大?。?/td> | 1734K |

| 代理商: | SKKH132/22E |

by SEMIKRON

0898

B 1 – 63

V

RSM

V

RRM

(dv/

dt)

cr

I

TRMS

(maximum value for continuous operation)

220 A

250 A

I

TAV

(sin. 180; T

case

= 80 °C)

148 A

168 A

SKKT

132/08 D

132/12 E

132/14 E

132/16 E

132/18 E

132/20 E

132/22 E

–

V

DRM

220 A

250 A

V

V

V/

μ

s

148 A

SKKH

132/08 D

132/12 E

132/14 E

132/16 E

132/18 E

132/20 E

132/22 E

168 A

SKKH

162/08 D

162/12 E

162/14 E

162/16 E

162/18 E

–

–

900

1300

1500

1700

1900

2100

2300

800

1200

1400

1600

1800

2000

2200

500

1000

1000

1000

1000

1000

1000

SKKT

162/08 D

162/12 E

162/14 E

162/16 E

162/18 E

–

Symbol Conditions

SKKT 132

SKKH 132

130 (87 °C)

77 / 100

170 / 200

250 / 320

240 / 3 x 163

305 / 3 x 250

4 700

4 000

110 000

80 000

SKKT 162

SKKH 162

160 (83 °C)

–

190 / 230

290 / 360

265 / 3 x 185

333 / 3 x 312

5 400

5 000

145 000

125 000

Units

I

TAV

I

D

I

RMS

sin. 180; (T

case

= . . .)

B2/B6

T

amb

= 45 °C; P 3/180

T

amb

= 35 °C; P 3/180 F

P 16/200 F

P 3/180 F

P 16/200 F

W1/W3

A

A

A

A

A

A

A

A

I

TSM

i

2

t

T

vj

= 25 °C; 10 ms

T

vj

= 125 °C; 10 ms

T

vj

= 25 °C; 8,3 ... 10 ms

T

vj

= 125 °C; 8,3 ... 10 ms

T

vj

= 25 °C; I

G

= 1 A

A

2

s

A

2

s

t

gd

t

gr

(di/dt)

cr

t

q

I

H

I

L

V

T

V

T(TO)

r

T

I

DD

; I

RD

V

GT

I

GT

V

GD

I

GD

R

thjc

di

G

/dt = 1 A/

μ

s

V

D

= 0,67

.

V

DRM

T

vj

= 125 °C

T

vj

= 125 °C

T

vj

= 25 °C; typ./max.

T

vj

= 25 °C; R

G

= 33

; typ./max.

T

vj

= 25 °C; I

T

= 500 A

T

vj

= 125 °C

T

vj

= 125 °C

T

vj

= 125 °C; V

DRM;

V

RRM

T

vj

= 25 °C; d.c.

T

vj

= 25 °C; d.c.

T

vj

= 125 °C; d.c.

T

vj

= 125 °C; d.c.

cont.

sin. 180

per thyristor /

rec. 120

per module

1

2

μ

s

μ

s

A/

μ

s

μ

s

mA

A

V

V

m

mA

V

mA

V

mA

°C/W

°C/W

°C/W

°C/W

°C

V~

Nm

Nm

m/s

2

g

A 50

A 61

200

typ. 50 . . . 150

150 / 400

0,3 / 1

max. 1,8

1

1,6

max. 40

max. 1,6

0,85

1,5

max. 40

2

150

0,25

10

0,18 / 0,09

0,19 / 0,095

0,21 / 0,105

0,17 / 0,085

0,18 / 0,09

0,20 / 0,10

R

thch

T

vj,

T

stg

V

isol

M

1

M

2

a

w

Case

0,10 / 0,05

– 40 ... + 125

3600 / 3000

5 (44 lb. in.) + 15 %

2)

5 (44 lb. in.) + 15 %

5

.

9,81

250

SKKT: A 21

SKKH: A 22

a. c. 50 Hz; r.m.s; 1 s/1 min

to heatsink

to terminals

approx.

→

page B 1 – 96

SKMT:

SKNH:

SEMIPACK

2

Thyristor / Diode Modules

SKKT 132

SKMT 132

1)

SKKT 162

SKKH 132

SKNH 132

1)

SKKH 162

Features

Heat transfer through aluminium

oxide ceramic isolated metal

baseplate

Hard soldered joints for high

reliability

UL recognized, file no. E 63 532

Typical Applications

DC motor control (e.g. for

machine tools)

Temperature control (e.g. for

ovens, chemical processes)

Professional light dimming

(studios, theaters)

SKNH 162 for DC braking of

induction motors, for circuit see

page B 1 – 97

1)

SKMT 132, SKNH 132 available

on request

2)

See the assembly instructions

SKKT

SKMT

SKKH

SKNH

SI (US) units

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| SKKT132/20E | 204.1 A, 2000 V, SCR |

| SKKH210/14E | 350 A, 1400 V, SCR |

| SKKH210/16E | 350 A, 1600 V, SCR |

| SKKH210/20E | 350 A, 2000 V, SCR |

| SKKH210/22E | 350 A, 2200 V, SCR |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| SKKH15 | 制造商:SEMIKRON 制造商全稱:Semikron International 功能描述:Thyristor / Diode Modules |

| SKKH15/04D | 制造商:SEMIKRON 制造商全稱:Semikron International 功能描述:Thyristor / Diode Modules |

| SKKH15/05E | 制造商:SEMIKRON 制造商全稱:Semikron International 功能描述:Thyristor / Diode Modules |

| SKKH15/06D | 制造商:SEMIKRON 制造商全稱:Semikron International 功能描述:Thyristor / Diode Modules |

| SKKH15/06E | 制造商:SEMIKRON 功能描述:THYRISTOR MODULE |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。