- 您現在的位置:買賣IC網 > PDF目錄224275 > ME-PLCC-32-AT (METHODE ELECTRONICS INC) PLCC32, IC SOCKET PDF資料下載

參數資料

| 型號: | ME-PLCC-32-AT |

| 廠商: | METHODE ELECTRONICS INC |

| 元件分類: | 插座 |

| 英文描述: | PLCC32, IC SOCKET |

| 文件頁數: | 5/6頁 |

| 文件大?。?/td> | 632K |

| 代理商: | ME-PLCC-32-AT |

1700 Hicks Road Rolling Meadows, IL 60008 USA

Telephone: 847.392.3500 Fax: 847.392.9404

email: mcpsales@methode.com Web Page: www.methode.com

Connector Products

Specifications

Materials

Contact Material: Beryllium Copper

Contact Plating: Tin/Lead over Nickel

Insulator Material: Polyphenylene Sulfide, UL 94V-0

Operating Temperature: -50

°C to +125°C

Mechanical Performance

Durability: Per MIL-STD-1344, method 2016, 100 cycles

Vibration: Per MIL-STD-810C, method 514.2, 10-

20,000 Hz, 5 Gs

Shock: Per MIL-STD-810C, method 516.2, 35 Gs

Acceleration: Per MIL-STD-810C, method 513.2, 15 Gs

Electrical Performance

Contact Interface Resistance:

Initial: 6.5 milliohms average

Final: 15.0 milliohms maximum after testing

Insulation Resistance: Greater than 1 x 104 megohms

Dielectric Strength: 1000 VAC continuous for 1 minute

Capacitance: Less than 1.0 pF at 1,000 Hz

Inductance:

Self: 5.0 nH, maximum at 500 KHz

Mutual: 1.0 nH, maximum at 500 KHz

Environmental Performance

Thermal Shock: Per MIL-STD-1344, method 1002,

condition A, cycled form -55

°C to +85°C no

discontinuity or physical damage

Temperature/Humidity: Per MIL-STD-1344, method

1002, 85

°C/85% relative humidity

Agency Approvals:

UL Component Recognition File E-48567

Canadian Standards Association File 52212

Methode has designed this PLCC socket to take full

advantage of surface mount technology. The exclusive

visible internal solder tails along with the use of quality

high temperature materials assure compatibility with all

common reflow processes. This unique configuration

combines the handling and real estate advantages of the

J-lead with the processing, inspection and repair

advantages of the gull wing. The small overall package

dimensions allow the use of sockets with minimum

sacrifice in space. A center pad is provided in insure

structural integrity and provide a surface for vacuum pick

up or adhesive bonding. The socket uses the same

board pattern as the standard JEDEC chip and the

exposed tails insure full cleaning with maximum

drainage. The exclusive high pressure contact system

eliminates the need for gold plating while assuring a

reliable, cost effective way to provide a surface mount

socket for lead chip carriers.

Features

s

Patented design allows for inspection and repair of

surface mount connections

s

.200 (5.08) total mated height

s

Uses the same mounting pattern as mating chip

s

Fully compatible with all surface mount processing

s

Exposed solder tails for cleaning and maximum

drainage

s

Center pad for vacuum pick and place robotic

assemble and/or adhesive bonding

s

Optional polarizing pegs available

s

Visual and mechanical polarization

s

Extraction tool slots

s

Contact design provides constant downward force on

chip to prevent disengagement

s

Preloaded contact provides low insertion force while

maintaining high normal force

s

Available in 20, 28, 32, 44, 52, 68 and 84 positions

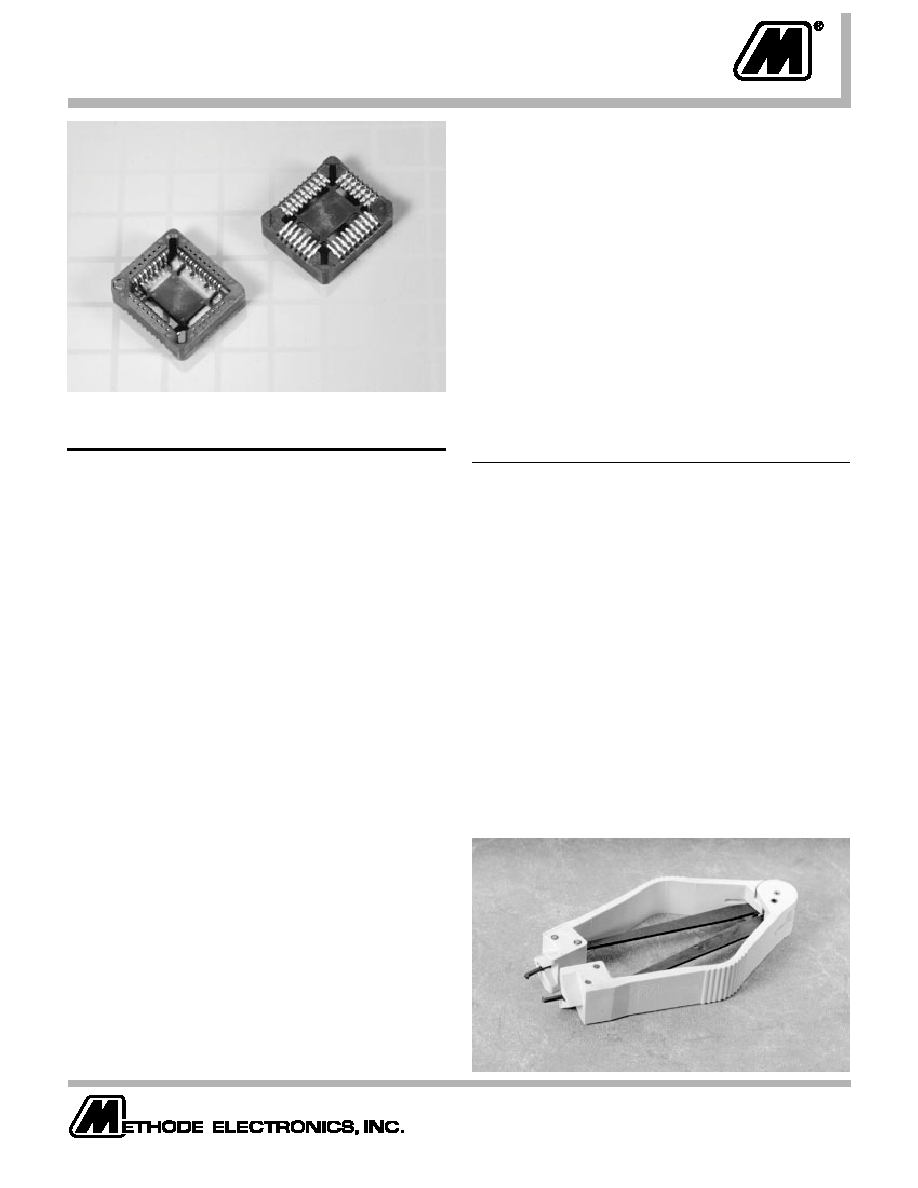

Low Profile/Surface Mount

Chip Carrier Socket

Patent No. 4,934,944

Extraction Tool CT-2102

Designed specifically

for chip extraction from

populated P.C. boards

5

相關PDF資料 |

PDF描述 |

|---|---|

| ME-PLCC-44-AT | PLCC44, IC SOCKET |

| ME23ZBA-155.520MHZ | CRYSTAL OSCILLATOR, CLOCK, 155.52 MHz, PECL OUTPUT |

| ME26YAD120.0000MHZ | CRYSTAL OSCILLATOR, CLOCK, 120 MHz, PECL 10KH OUTPUT |

| MEC1-130-02-F-D-A | 60 CONTACT(S), FEMALE, STRAIGHT SINGLE PART CARD EDGE CONN, SURFACE MOUNT, SOCKET |

| MEC1-130-02-L-D-LC | 60 CONTACT(S), FEMALE, STRAIGHT SINGLE PART CARD EDGE CONN, SURFACE MOUNT, SOCKET |

相關代理商/技術參數 |

參數描述 |

|---|---|

| MEPLCC-68-AT | 制造商:Methode Electronics Inc 功能描述:Conn PLCC Socket SKT 68 POS 1.27mm Solder ST Thru-Hole |

| MEPY1-0 | 制造商:ABB Low Voltage Products and Systems 功能描述:EMPTY PLASTIC ENCL 1-HOLE YEL 制造商:MISCELLANEOUS 功能描述: |

| MEQ102M2VB075 | 制造商:RFE 制造商全稱:RFE international 功能描述:ALUMINUM ELECTROLYTIC CAPACITORS MEQ Series: Screw Term, 85C, 20,000hrs |

| MEQ61841001 | 制造商:LG Corporation 功能描述:Igniter |

| MER1 | 制造商:MURATA-PS 制造商全稱:Murata Power Solutions Inc. 功能描述:1kVDC Isolated 1W Single Output DC/DC Converters |

發(fā)布緊急采購,3分鐘左右您將得到回復。