- 您現(xiàn)在的位置:買(mǎi)賣(mài)IC網(wǎng) > PDF目錄181670 > MCJM1A-48P0D6-0.5 48 CONTACT(S), MALE, STRAIGHT TELECOM AND DATACOM CONNECTOR, SOLDER, PLUG PDF資料下載

參數(shù)資料

| 型號(hào): | MCJM1A-48P0D6-0.5 |

| 元件分類(lèi): | 電信和以太網(wǎng)連接器 |

| 英文描述: | 48 CONTACT(S), MALE, STRAIGHT TELECOM AND DATACOM CONNECTOR, SOLDER, PLUG |

| 文件頁(yè)數(shù): | 1/2頁(yè) |

| 文件大小: | 118K |

| 代理商: | MCJM1A-48P0D6-0.5 |

Catalog 1308638

Dimensions are in inches and

Dimensions are shown for

USA: 1-800-522-6752

South America: 55-11-3611-1514

Revised 8-05

millimeters unless otherwise

reference purposes only.

Canada: 1-905-470-4425

Hong Kong: 852-2735-1628

specified. Values in brackets

Specifications subject

Mexico: 01-800-733-8926

Japan: 81-44-844-8013

www.tycoelectronics.com

are metric equivalents.

to change.

C. America: 52-55-5-729-0425

UK: 44-141-810-8967

Rectangular Connectors

48

JACKMATE MCJM Series Metal Shell Center Jackscrew Connectors

Technical and Performance

Data for Metal Shell

Electrical

Contact Resistance — The average

mated contact resistance is 4 milliohms,

with a maximum value of 8 milliohms,

using standard 24 AWG solid copper

leads when measured directly behind the

crimp joints of the mated pin and socket

contacts. The average resistance value at

100 microvolts is 4.8 milliohms.

Dielectric Withstanding Voltage

(60 Hz rms room temperature) —

Solder Pots: 600 VAC at sea level; 150

VAC at 70,000 feet [21,336m].

Wire Terminations: 750 VAC at sea level;

200 VAC at 70,000 feet [21,336m].

Corrosion Resistance (Per MIL-

STD-202C, Method 101B, Condition

B) — Both mated and unmated samples

do not exceed the maximum allowable

contact resistance (8 milliohms) when

subjected to the 48 hour salt spray test.

Durability — The contact resistance

after 500 mating cycles is less than the

maximum allowable, 8 milliohms.

Insulation Resistance — Greater than

5,000 megohms at room temperature for

the materials listed under “Materials”.

Maximum Current Carrying

Capacity — No. 24 contact 3 amperes.

It must be recognized, however, that all

the wires to a connector will not carry

their maximum current under all envi-

ronmental conditions due to wire tem-

perature.

Mechanical

Contact Engaging & Separation

Forces — 8.0 oz. max. [2.22N] (eng.),

0.5 oz. min.[.14N] (sep.).

Environmental

Temperature Range (Operating) —

-67°F to 302°F [-55°C to 150°C] for

Diallyl Phthalate.

Vibration (Per MIL-STD-202C,

Method 204-A, Condition D) — No

discontinuity in excess of 1 sec. dur-

ing twelve 20 minute sweeps from 10 to

2000 CPS at .06 double amplitude or 20

G forces, whichever is less.

Materials

Insulator — Diallyl Phthalate per MIL-

M-14, Type SDG-F.

Contacts — Pin contact: copper alloy

and beryllium copper alloy make up the

complete construction; Socket contact:

copper alloy.

Body Shells — Pin body shell: stain-

less steel, Types 304, Condition A per

QQ-S-766; Socket body shell: aluminum

alloy per QQ-A-591, A-380 alloy.

Hardware — Corrosion resistant

stainless steel.

Finishes

Contacts — Standard finish is

0.000050 [0.00127] gold over copper

flash per MIL-G-45204, Type II.

Body Shells — Pin body shell: passi-

vated per MIL-F-14072 (E-300); Socket

body shell: electroless nickel per AMS

204, Class 3, except thickness is

0.001/0.0015 [0.025/0.038].

Hardware — Passivated per

QQ–P–35.

Note: Insulators are molded into

their metal shells —

No bonded joint is used.

*Standard material used unless

otherwise specified.

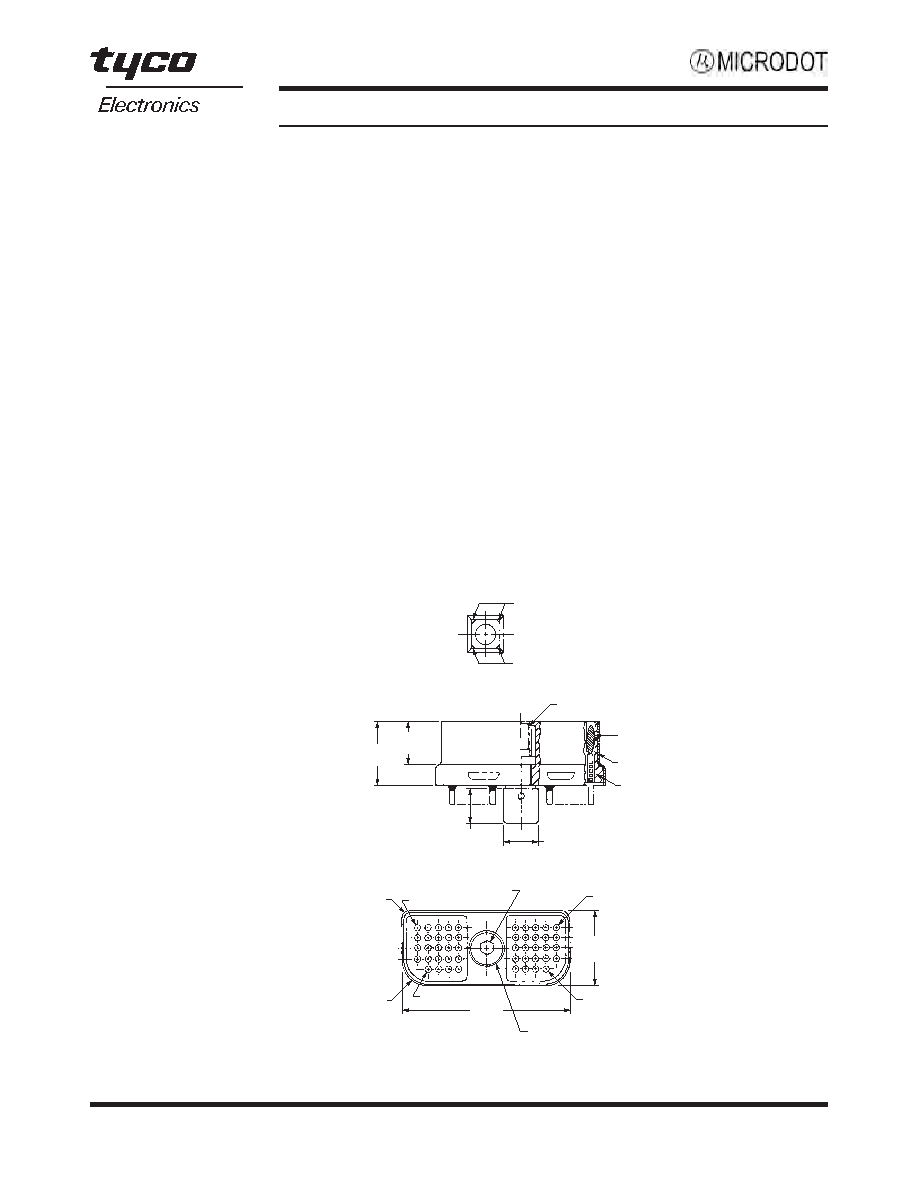

B Polarization

A Polarization

Insert

Shell

Contact Pin

Jackscrew 2-56 UNC-2B Thd.

.300

[7.62]

.199

[5.05]

.180

[4.57]

.187

[4.75]

.830

[21.08]

.125

[3.18]

.350

[8.89]

#41

#1

#48

Rad.

Typ.

.046

[1.17]

#10

Rad.

Typ.

.078

[1.98]

Hex

Socket

Jackscrew

Plug (Pin Side)

Shell Type M1

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| MCJM1A-48P0D7-0.5 | 48 CONTACT(S), MALE, STRAIGHT TELECOM AND DATACOM CONNECTOR, SOLDER, PLUG |

| MCJM1A-48P0D8-0.5 | 48 CONTACT(S), MALE, STRAIGHT TELECOM AND DATACOM CONNECTOR, SOLDER, PLUG |

| MCJM1A-48P0D9-0.5 | 48 CONTACT(S), MALE, STRAIGHT TELECOM AND DATACOM CONNECTOR, SOLDER, PLUG |

| MCJM1A-48P0G1-0.5 | 48 CONTACT(S), MALE, STRAIGHT TELECOM AND DATACOM CONNECTOR, SOLDER, PLUG |

| MCJM1A-48P0G2-0.5 | 48 CONTACT(S), MALE, STRAIGHT TELECOM AND DATACOM CONNECTOR, SOLDER, PLUG |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| MCJR1D00 | 制造商:Veeder-Root Company 功能描述: |

| MCJR1S00 | 制造商:Veeder-Root Company 功能描述: 制造商:DANAHER - INDUSTRIAL/SPECIALTY 功能描述:MULTIFUNCTION COUNTER, No. of Digits / Alpha:8, Digit Height:7.6mm, Power Consum |

| MCJR2D00 | 制造商:DANAHER SPECIALTY PRODUCTS 功能描述:Counter, programmable, 2 preset, predetermining, 10-26VDC, 5 digit |

| MCJR2S00 | 制造商:DANAHER SPECIALTY PRODUCTS 功能描述:COUNTER, MAXJR COUNT 2; 115/230 VAC 制造商:DANAHER CONTROLS 功能描述:MULTIFUNCTION COUNTER 制造商:DANAHER CONTROLS 功能描述:MULTIFUNCTION COUNTER; No. of Digits / Alpha:5; Digit Height:14.2mm; Power Consumption:6VA; Panel Cutout Height:45.21mm; Panel Cutout Width:90.93mm; Counting Speed:10kHz; Operating Temperature Min:0C; Operating Temperature Max:50C ;RoHS Compliant: NA |

| MCK0209 | 制造商:FCI 功能描述: |

發(fā)布緊急采購(gòu),3分鐘左右您將得到回復(fù)。