- 您現在的位置:買賣IC網 > PDF目錄379308 > MC33030DW (MOTOROLA INC) DC SERVO MOTOR CONTROLLER/DRIVER PDF資料下載

參數資料

| 型號: | MC33030DW |

| 廠商: | MOTOROLA INC |

| 元件分類: | 運動控制電子 |

| 英文描述: | DC SERVO MOTOR CONTROLLER/DRIVER |

| 中文描述: | BRUSH DC MOTOR CONTROLLER, 1 A, PDSO16 |

| 封裝: | PLASTIC, SOP-16 |

| 文件頁數: | 8/16頁 |

| 文件大小: | 322K |

| 代理商: | MC33030DW |

MC33030

8

MOTOROLA ANALOG IC DEVICE DATA

Inverting

Input

Over–Voltage

Monitor

Drive Brake Logic

+

Drive

Output A

14

Drive

Output B

VCC

Motor

10

11

Power

H–Switch

Q Brake

Q Brake

Over–Current

Monitor

Over–Current

Reference

ROC

15

+

16

CDLY

Over–Current

Delay

5.5

μ

A

7.5 V

Ref.

50 k

R

S

Over–

Current

Latch

Q Drive

S

Q Drive

R

Brake Enable

Direction

Latch

18 V

Ref.

Gearbox and Linkage

Gnd

4, 5,12,13

+

Window

Detector

VCC

Reference

Input Filter

20 k

35

μ

A

A

B

3.0 k

3.0 k

35

μ

A

20 k

Non–

Inverting

Input

9

Input

Filter

+

VCC

Output

20 k

0.3 mA

8

20 k

Error Amp

Error Amp

Output Filter/

Feedback

Input

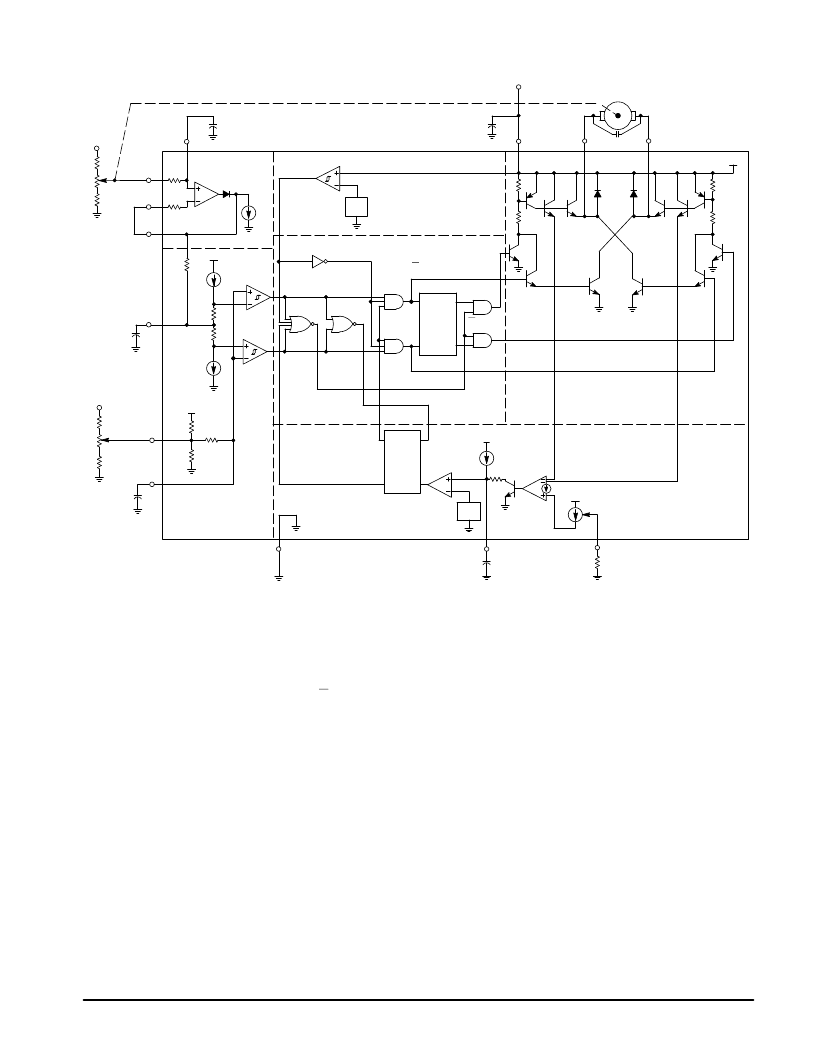

Figure 17. Representative Block Diagram and Typical Servo Application

Q

Q

Q

100 k

2

1

Q

3

6

Reference

Input

7

100 k

If VPin 3 should continue to rise and become greater than V2,

the actuator will have over shot the dead zone range and cause

the motor to run in Direction A until VPin 3 is equal to V3. The

Drive/Brake behavior for Direction A is identical to that of B.

Overshooting the dead zone range in both directions can cause

the servo system to continuously hunt or oscillate. Notice that the

last motor run–direction is stored in the direction latch. This

information is needed to determine whether Q or Q Brake is to be

enabled when VPin 3 enters the dead zone range. The dashed

lines in [8,9] indicate the resulting waveforms of an over–current

condition that has exceeded the programmed time delay. Notice

that both Drive Outputs go into a high impedance state until VPin

2 is readjusted so that VPin 3 enters or crosses through the dead

zone [7, 4].

The inputs of the Error Amp and Window Detector can be

susceptible to the noise created by the brushes of the DC

motor and cause the servo to hunt. Therefore, each of these

inputs are provided with an internal series resistor and are

pinned out for an external bypass capacitor. It has been

found that placing a capacitor with short leadsdirectly across

the brushes will significantly reduce noise problems. Good

quality RF bypass capacitors in the range of 0.001 to 0.1

μ

F

may be required. Many of the more economical motors will

generate significant levels of RF energy over a spectrum that

extends from DC to beyond 200 MHz. The capacitance value

and method of noise filtering must be determined on a

system by system basis.

Thus far, the operating description has been limited to

servo systems in which the motor mechanically drives a

potentiometer for position sensing. Figures 19, 20, 27, and 31

show examples that use light, magnetic flux, temperature,

and pressure as a means to drive the feedback element.

Figures 21, 22 and 23 are examples of two position, open

loop servo systems. In these systems, the motor runs the

actuator to each end of its travel limit where the Over–Current

Monitor detects a locked rotor condition and shuts down the

drive. Figures 32 and 33 show two possible methods of using

the MC33030 as a switching motor controller. In each

example a fixed reference voltage is applied to Pin 2. This

causes Vpin 3 to be less than V4 and Drive Output A, Pin 14,

to be in a low state saturating the TIP42 transistor. In Figure

32, the motor drives a tachometer that generates an ac

voltage proportional to RPM. This voltage is rectified, filtered,

divided down by the speed set potentiometer, and applied to

Pin. 8. The motor will accelerate until VPin 3 is equal to V1 at

which time Pin 14 will go to a high state and terminate the

motor drive. The motor will now coast until VPin 3 is less than

V4 where upon drive is then reapplied. The system operation

of Figure 31 is identical to that of 32 except the signal at Pin

3 is an amplified average of the motors drive and back EMF

voltages. Both systems exhibit excellent control of RPM with

variations of VCC; however, Figure 32 has somewhat better

torque characteristics at low RPM.

相關PDF資料 |

PDF描述 |

|---|---|

| MC33030 | DC SERVO MOTOR CONTROLLER/DRIVER |

| MC33030DW | DC SERVO MOTOR CONTROLLER/DRIVER |

| MC33030P | DC SERVO MOTOR CONTROLLER/DRIVER |

| MC33030P | DC SERVO MOTOR CONTROLLER/DRIVER |

| MC33161 | Tag-it(TM) HF-I Pro Transponder Inlays 24.2-mm Circular 0-RFIDN -25 to 70 |

相關代理商/技術參數 |

參數描述 |

|---|---|

| MC33030DWG | 功能描述:馬達/運動/點火控制器和驅動器 ANA DC SERVO MOT CNTRL RoHS:否 制造商:STMicroelectronics 產品:Stepper Motor Controllers / Drivers 類型:2 Phase Stepper Motor Driver 工作電源電壓:8 V to 45 V 電源電流:0.5 mA 工作溫度:- 25 C to + 125 C 安裝風格:SMD/SMT 封裝 / 箱體:HTSSOP-28 封裝:Tube |

| MC33030DWR2 | 功能描述:馬達/運動/點火控制器和驅動器 DC Brushless Motor RoHS:否 制造商:STMicroelectronics 產品:Stepper Motor Controllers / Drivers 類型:2 Phase Stepper Motor Driver 工作電源電壓:8 V to 45 V 電源電流:0.5 mA 工作溫度:- 25 C to + 125 C 安裝風格:SMD/SMT 封裝 / 箱體:HTSSOP-28 封裝:Tube |

| MC33030DWR2G | 功能描述:馬達/運動/點火控制器和驅動器 DC Brushless Motor Controller RoHS:否 制造商:STMicroelectronics 產品:Stepper Motor Controllers / Drivers 類型:2 Phase Stepper Motor Driver 工作電源電壓:8 V to 45 V 電源電流:0.5 mA 工作溫度:- 25 C to + 125 C 安裝風格:SMD/SMT 封裝 / 箱體:HTSSOP-28 封裝:Tube |

| MC33030P | 功能描述:馬達/運動/點火控制器和驅動器 DC Brushless Motor RoHS:否 制造商:STMicroelectronics 產品:Stepper Motor Controllers / Drivers 類型:2 Phase Stepper Motor Driver 工作電源電壓:8 V to 45 V 電源電流:0.5 mA 工作溫度:- 25 C to + 125 C 安裝風格:SMD/SMT 封裝 / 箱體:HTSSOP-28 封裝:Tube |

| MC33030PG | 功能描述:馬達/運動/點火控制器和驅動器 DC Brushless Motor Controller RoHS:否 制造商:STMicroelectronics 產品:Stepper Motor Controllers / Drivers 類型:2 Phase Stepper Motor Driver 工作電源電壓:8 V to 45 V 電源電流:0.5 mA 工作溫度:- 25 C to + 125 C 安裝風格:SMD/SMT 封裝 / 箱體:HTSSOP-28 封裝:Tube |

發(fā)布緊急采購,3分鐘左右您將得到回復。