- 您現(xiàn)在的位置:買(mǎi)賣(mài)IC網(wǎng) > PDF目錄369795 > LM6321MX Analog Buffer/Voltage Follower PDF資料下載

參數(shù)資料

| 型號(hào): | LM6321MX |

| 英文描述: | Analog Buffer/Voltage Follower |

| 中文描述: | 模擬緩沖器/電壓跟隨 |

| 文件頁(yè)數(shù): | 6/10頁(yè) |

| 文件大小: | 208K |

| 代理商: | LM6321MX |

Application Hints

HEATSINK REQUIREMENTS

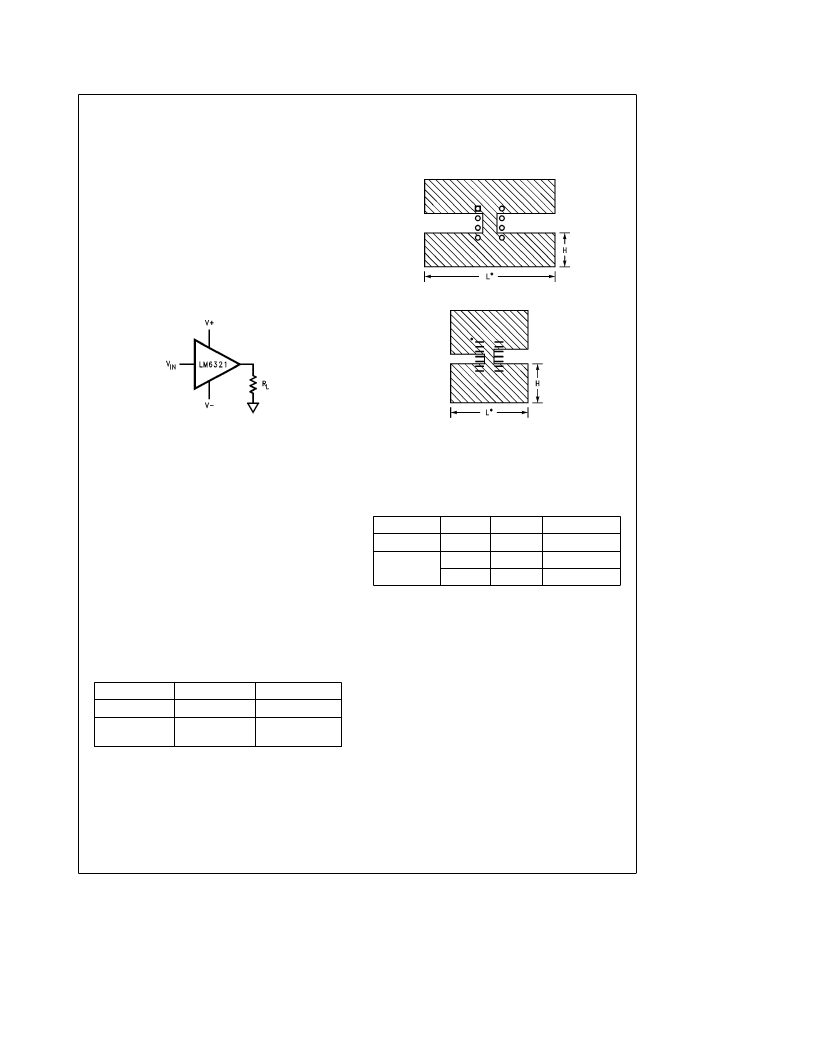

A heatsink may be required with the LM6321 depending on

the maximum power dissipation and maximum ambient tem-

perature of the application. Under all possible operating

conditions, the junction temperature must be within the

range specified under Absolute Maximum Ratings.

To determine if a heatsink is required, the maximum power

dissipated by the buffer, P(max), must be calculated. The

formula for calculating the maximum allowable power dissi-

pation in any application is P

D

e

(T

J

(max)

b

T

A

)/

i

JA

. For

the simple case of a buffer driving a resistive load as in

Figure 2, the maximum DC power dissipation occurs when

the output is at half the supply. Assuming equal supplies,

the formula is P

D

e

I

S

(2V

a

)

a

V

a

2

/2 R

L

.

TL/H/9223–8

FIGURE 2

Figure 3 shows copper patterns which may be used to dissi-

pate heat from the LM6321.

8-Pin DIP

TL/H/9223–9

14-Pin SO

TL/H/9223–10

*

For best results, use L

e

2H

FIGURE 3. Copper Heatsink Patterns

The next parameter which must be calculated is the maxi-

mum allowable temperature rise, T

R

(max). This is calculat-

ed by using the formula:

T

R

(max)

e

T

J

(max)

b

T

A

(max)

where: T

J

(max) is the maximum allowable junction tempera-

ture

T

A

(max) is the maximum ambient temperature

Using the calculated values for T

R

(max) and P(max), the

required value for junction-to-ambient thermal resistance,

i

(J–A)

, can now be found:

i

(J–A)

e

T

R

(max)/P(max)

The heatsink for the LM6321 is made using the PC board

copper. The heat is conducted from the die, through the

lead frame (inside the part), and out the pins which are sol-

dered to the PC board. The pins used for heat conduction

are:

TABLE I

Part

Package

Pins

LM6321N

8-Pin DIP

1, 4, 5, 8

LM6321M

14-Pin SO

1, 2, 3, 6, 7,

8, 9, 13, 14

Table II shows some values of junction-to-ambient thermal

resistance (

i

J–A

) for values of L and W for 2 oz. copper:

TABLE II

Package

L (in.)

H (in.)

i

J–A

(

§

C/W)

8-Pin DIP

2

0.5

47

14-Pin SO

1

0.5

69

2

1

57

6

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| LM6325 | |

| LM6402H | |

| LM6402L | |

| LM6405A | |

| LM6405H | |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| LM6321N | 制造商:National Semiconductor Corporation 功能描述:Voltage Follower, Single, 8 Pin, Plastic, DIP |

| LM6325 | 制造商:未知廠(chǎng)家 制造商全稱(chēng):未知廠(chǎng)家 功能描述: |

| LM6325N | 制造商:NSC 制造商全稱(chēng):National Semiconductor 功能描述:High Speed Buffer |

| LM632-DA | 功能描述:基本/快動(dòng)開(kāi)關(guān) Foot Switch RoHS:否 制造商:Omron Electronics 觸點(diǎn)形式:SPDT 執(zhí)行器:Lever 電流額定值:5 A 電壓額定值 AC:250 V 電壓額定值 DC:30 V 功率額定值: 工作力:120 g IP 等級(jí):IP 67 NEMA 額定值: 端接類(lèi)型:Wire 安裝:Panel |

| LM632-DC3A | 功能描述:基本/快動(dòng)開(kāi)關(guān) Foot Switch RoHS:否 制造商:Omron Electronics 觸點(diǎn)形式:SPDT 執(zhí)行器:Lever 電流額定值:5 A 電壓額定值 AC:250 V 電壓額定值 DC:30 V 功率額定值: 工作力:120 g IP 等級(jí):IP 67 NEMA 額定值: 端接類(lèi)型:Wire 安裝:Panel |

發(fā)布緊急采購(gòu),3分鐘左右您將得到回復(fù)。