- 您現(xiàn)在的位置:買賣IC網 > PDF目錄358845 > LM350T (FAIRCHILD SEMICONDUCTOR CORP) 3-Terminal 3A Positive Adjustable Voltage Regulator PDF資料下載

參數資料

| 型號: | LM350T |

| 廠商: | FAIRCHILD SEMICONDUCTOR CORP |

| 元件分類: | 基準電壓源/電流源 |

| 英文描述: | 3-Terminal 3A Positive Adjustable Voltage Regulator |

| 中文描述: | 1.2 V-33 V ADJUSTABLE POSITIVE REGULATOR, SFM3 |

| 封裝: | TO-220, 3 PIN |

| 文件頁數: | 2/12頁 |

| 文件大小: | 172K |

| 代理商: | LM350T |

LM350

2

MOTOROLA ANALOG IC DEVICE DATA

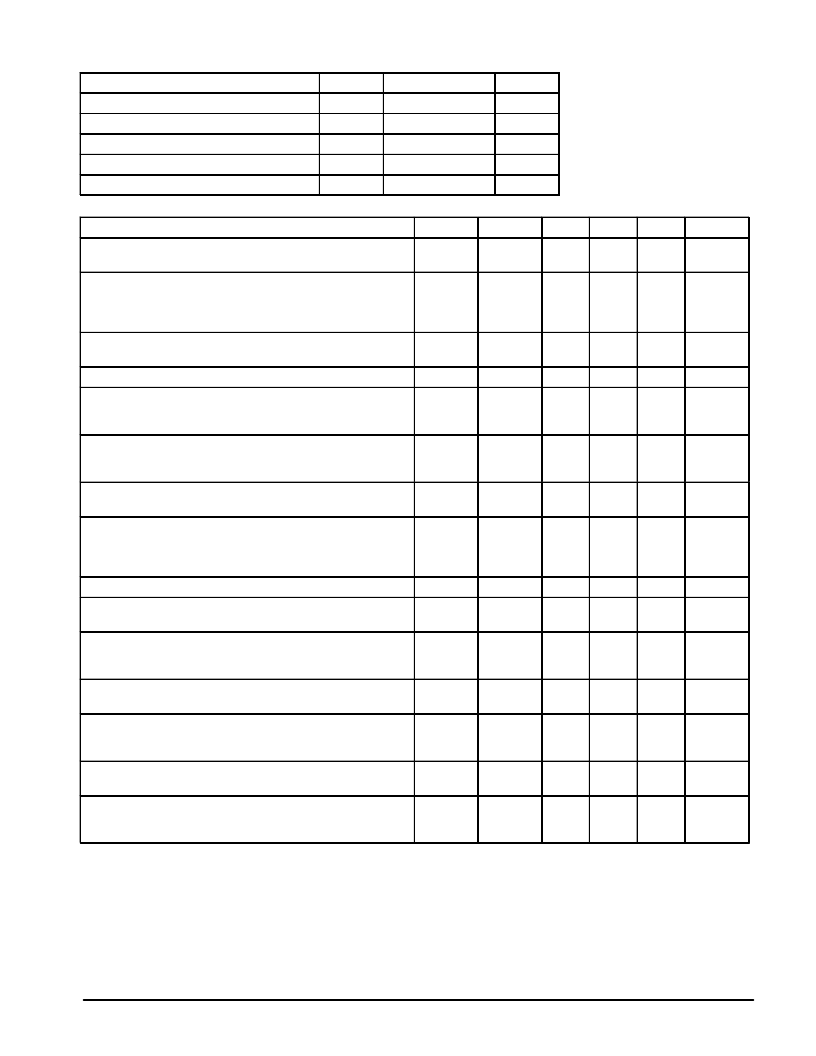

MAXIMUM RATINGS

Rating

Symbol

Value

Unit

Input–Output Voltage Differential

VI–VO

PD

TJ

Tstg

Tsolder

35

Vdc

Power Dissipation

Internally Limited

W

Operating Junction Temperature Range

–40 to +125

°

C

Storage Temperature Range

–65 to +150

°

C

Soldering Lead Temperature (10 seconds)

300

°

C

ELECTRICAL CHARACTERISTICS

(VI–VO = 5.0 V; IL = 1.5 A; TJ = Tlow to Thigh; Pmax [Note 1], unless otherwise noted.)

Characteristics

Figure

Symbol

Min

Typ

Max

Unit

Line Regulation (Note 2)

TA = 25

°

C, 3.0 V

≤

VI–VO

≤

35 V

1

Regline

–

0.0005

0.03

%/V

Load Regulation (Note 2)

TA = 25

°

C, 10 mA

≤

Il

≤

3.0 A

VO

≤

5.0 V

VO

≥

5.0 V

2

Regload

–

–

5.0

0.1

25

0.5

mV

% VO

Thermal Regulation, Pulse = 20 ms,

(TA = +25

°

C)

Regtherm

–

0.002

–

% VO/W

Adjustment Pin Current

3

IAdj

IAdj

–

50

100

μ

A

Adjustment Pin Current Change

3.0 V

≤

VI–VO

≤

35 V

10 mA

≤

IL

≤

3.0 A, PD

≤

Pmax

1,2

–

0.2

5.0

μ

A

Reference Voltage

3.0 V

≤

VI–VO

≤

35 V

10 mA

≤

IO

≤

3.0 A, PD

≤

Pmax

3

Vref

1.20

1.25

1.30

V

Line Regulation (Note 2)

3.0 V

≤

VI–VO

≤

35 V

1

Regline

–

0.02

0.07

%/V

Load Regulation (Note 2)

10 mA

≤

IL

≤

3.0 A

VO

≤

5.0 V

VO

≥

5.0 V

Temperature Stability (Tlow

≤

TJ

≤

Thigh)

Minimum Load Current to

Maintain Regulation (VI–VO = 35 V)

2

Regload

–

–

20

0.3

70

1.5

mV

% VO

3

TS

ILmin

–

1.0

–

% VO

mA

3

–

3.5

10

Maximum Output Current

VI–VO

≤

10 V, PD

≤

Pmax

VI–VO = 30 V, PD

≤

Pmax, TA = 25

°

C

3

Imax

3.0

0.25

4.5

1.0

–

–

A

RMS Noise, % of VO

TA= 25

°

C, 10 Hz

≤

f

≤

10 kHz

N

–

0.003

–

% VO

Ripple Rejection, VO = 10 V, f = 120 Hz (Note 3)

Without CAdj

CAdj = 10

μ

F

4

RR

–

66

65

80

–

–

dB

Long Term Stability, TJ = Thigh (Note 4)

TA= 25

°

C for Endpoint Measurements

3

S

–

0.3

1.0

%/1.0 k

Hrs.

Thermal Resistance, Junction–to–Case

Peak (Note 5)

Average (Note 6)

R

θ

JC

–

–

2.3

–

–

1.5

°

C/W

NOTES:

1.Tlow to Thigh = 0

°

to +125

°

C; Pmax = 25 W for LM350T; Tlow to Thigh = –40

°

to +125

°

C; Pmax = 25 W for LM350BT

2.Load and line regulation are specified at constant junction temperature. Changes in VO due to heating effects must be taken into account separately.

Pulse testing with low duty cycle is used.

3.CAdj, when used, is connected between the adjustment pin and ground.

4.Since Long–Term Stability cannot be measured on each device before shipment, this specification is an engineering estimate of average stability

from lot to lot.

5.Thermal Resistance evaluated measuring the hottest temperature on the die using an infrared scanner. This method of evaluation yields very

accurate thermal resistance values which are conservative when compared to the other measurement techniques.

6.The average die temperature is used to derive the value of thermal resistance junction to case (average).

相關PDF資料 |

PDF描述 |

|---|---|

| LM350 | 3-Terminal 3A Positive Adjustable Voltage Regulator |

| LM3520 | Integrated White LED Driver with Organic LED Display Power Supply |

| LM3526MX-H | Dual Port USB Power Switch and Over-Current Protection |

| LM3526MX-L | Dual Port USB Power Switch and Over-Current Protection |

| LM3526M-L | Dual Port USB Power Switch and Over-Current Protection |

相關代理商/技術參數 |

參數描述 |

|---|---|

| LM350T | 制造商:Texas Instruments 功能描述:V REG ADJ +1.2/33V TO-220-3 350 |

| LM350T | 制造商:Fairchild Semiconductor Corporation 功能描述:Linear Voltage Regulator IC |

| LM350T/LB01 | 制造商:Texas Instruments 功能描述:LDO Regulator Pos 1.2V to 33V 3A 3-Pin(3+Tab) TO-220 Rail |

| LM350T/LB07 | 制造商:Texas Instruments 功能描述:LDO Regulator Pos 1.2V to 33V 3A 3-Pin(3+Tab) TO-220 Rail |

| LM350T/NOPB | 功能描述:線性穩(wěn)壓器 - 標準 3-AMP ADJ REG RoHS:否 制造商:STMicroelectronics 輸出類型: 極性: 輸出電壓:1.8 V 輸出電流:150 mA 負載調節(jié): 最大輸入電壓:5.5 V 線路調整率: 最大工作溫度:+ 125 C 安裝風格:SMD/SMT 封裝 / 箱體:SOT-323-5L |

發(fā)布緊急采購,3分鐘左右您將得到回復。