- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄358001 > IMS-56800UH+/-10% (VISHAY DALE) 1 ELEMENT, 6800 uH, FERRITE-CORE, GENERAL PURPOSE INDUCTOR PDF資料下載

參數(shù)資料

| 型號: | IMS-56800UH+/-10% |

| 廠商: | VISHAY DALE |

| 元件分類: | 通用定值電感 |

| 英文描述: | 1 ELEMENT, 6800 uH, FERRITE-CORE, GENERAL PURPOSE INDUCTOR |

| 封裝: | RADIAL LEADED |

| 文件頁數(shù): | 1/3頁 |

| 文件大小: | 103K |

IMS-5

Vishay Dale

Document Number 34048

Revision 18-Oct-04

www.vishay.com

24

For technical questions, contact Magnetics@vishay.com

Inductors

Military, MIL-PRF-15305 Qualified, Type LT

and Commercial, Molded, Shielded

FEATURES

Wide inductance range in small package.

Flame retardant coating.

Electromagnetic shield-finest shield available.

Epoxy molded construction provides superior moisture

protection.

Precision performance, excellent reliability, sturdy construction.

NOTE: Listing of Military Standard does not imply qualification. Contact factory for latest government QPL information.

*Measured with full length lead. **

Rated DC Current:

Based on maximum temperature rise not to exceed 15

°

C at + 90

°

C ambient.

***

Incremental Current:

The minimum typical current at which the inductance will be decreased by 5% from its initial zero DC value.

*Not QPL'd.

ELECTRICAL SPECIFICATIONS

Inductance Tolerance:

±

10% standard.

±

5% available.

Insulation Resistance:

1000 Megohm minimum per

MIL-STD-202, Method 302, Test Condition B.

Dielectric Withstanding Voltage:

1000 VAC per

MIL-STD-202, Method 301 (sea level).

Percent Coupling

: 3% maximum per MIL-PRF-15305.

Operating Temperature Range:

- 55

°

C to + 105

°

C.

MECHANICAL SPECIFICATIONS

Terminal Strength:

5 pounds pull per MIL-STD-202,

Method 211, Test Condition A.

Weight:

IMS-5 = 0.85 grams maximum.

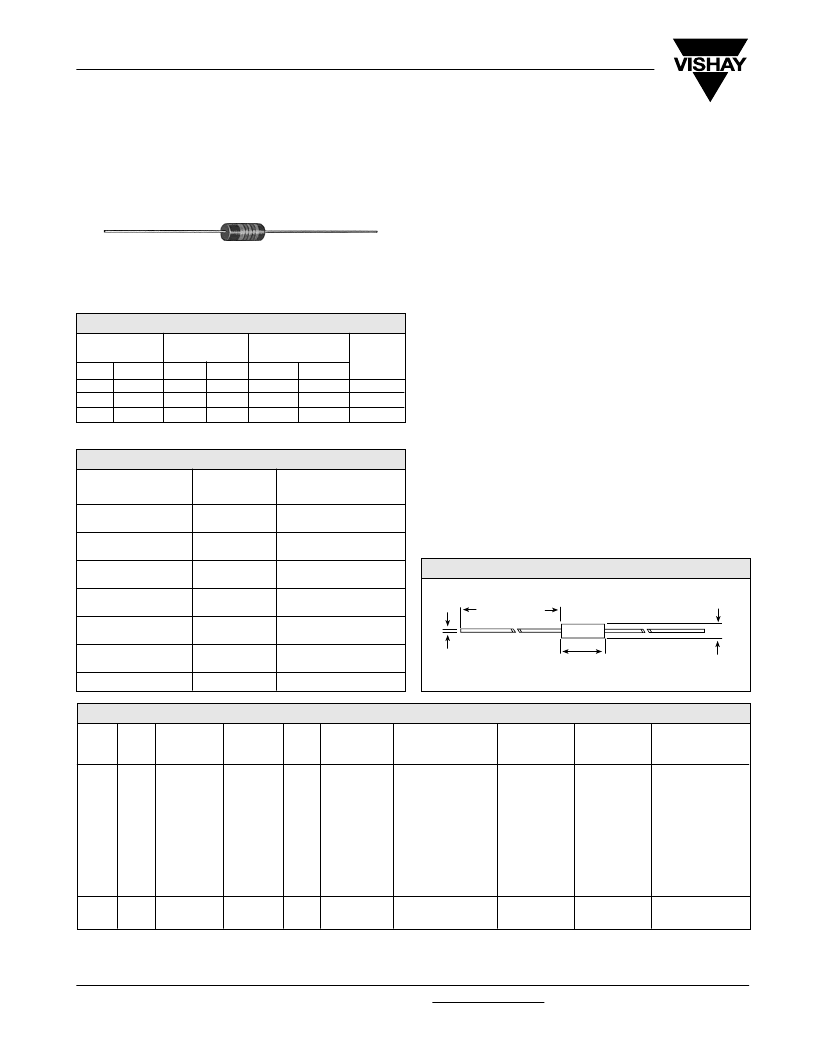

INDUCTANCE RANGE AND MILITARY STANDARD

FROM

.10

μ

H

1.0

μ

H

15.0

μ

H

TO

.82

μ

H

12.0

μ

H

100,000

μ

H

GRADE CLASS

1

1

1

CORE

SHIELD

MILITARY

STANDARD

MS75087

MS75088

MS75089

*

MATERIAL

CLASSIFICATION

INDUCTANCE

RANGE

A

A

A

Phenolic

Powd. Iron

Ferrite

Powd. Iron

Powd. Iron

Ferrite

SPECIFICATIONS

MIL-STD-202, Method 105

MIL-STD-202, Method 107

MIL-STD-202, Method 111

MIL-PRF-15305

MIL-PRF-15305

MIL-STD-202, Method 210

MIL-STD-202, Method 215

DIMENSIONS

in inches [millimeters]

0.025

±

0.002

[0.635

±

0.051]

0.162

±

0.010

[4.11

±

.254]

0.410

±

0.020

[10.41

±

0.508]

1.44

±

0.188

[36.57

±

4.78]

ENVIRONMENTAL PERFORMANCE

TEST

Barometric Pressure

Thermal Shock

Flammability

Overload

Low Temperature

Storage

Resistance to

Soldering Heat

Resistance to Solvents

CONDITIONS

Test Condition C

Test Condition A-1

—

—

—

Test Condition A

—

IND.

(

μ

H)

TOL.

MS75087

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

MS75088

-1

-2

MILITARY

TYPE

LT10K

191

192

193

194

195

196

197

198

199

200

201

202

LT10K

203

204

INCREMENTAL***

CURRENT

(mA)

RATED DC **

CURRENT

(mA)

DCR@25

°

C

MAX.

(Ohms)

SELF-RESONANT *

FREQ. MIN.

(MHz)

TEST FREQ.

L & Q

(MHz)

Q

MIN.

±

10%

±

10%

±

10%

±

10%

±

10%

±

10%

±

10%

±

10%

±

10%

±

10%

±

10%

±

10%

±

10%

±

10%

0.10

0.12

0.15

0.18

0.22

0.27

0.33

0.39

0.47

0.56

0.68

0.82

1.0

1.2

50

51

51

50

49

47

46

44

44

43

42

40

44

44

25.0

25.0

25.0

25.0

25.0

25.0

25.0

25.0

25.0

25.0

25.0

25.0

25.0

7.9

250.0

250.0

250.0

250.0

250.0

250.0

250.0

250.0

235.0

210.0

190.0

180.0

140.0

130.0

0.025

0.034

0.047

0.067

0.11

0.13

0.18

0.25

0.33

0.45

0.59

0.07

0.10

1790

1530

1470

1300

1100

855

780

670

565

490

420

370

1070

895

—

—

—

—

—

—

—

—

—

—

—

—

—

—

STANDARD ELECTRICAL SPECIFICATIONS

MILITARY

STANDARD

MATERIAL SPECIFICATIONS

Encapsulant:

Epoxy.

Standard Terminal:

#22 AWG tinned copper.

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| IMS-5WD-40100UH+/-10% | 1 ELEMENT, 100 uH, FERRITE-CORE, GENERAL PURPOSE INDUCTOR |

| IMS-5WD-4018UH+/-10% | 1 ELEMENT, 18 uH, FERRITE-CORE, GENERAL PURPOSE INDUCTOR |

| IMS-5WD-402200UH+/-10% | 1 ELEMENT, 2200 uH, FERRITE-CORE, GENERAL PURPOSE INDUCTOR |

| IMT4-7-F | DUAL PNP SMALL SIGNAL SURFACE MOUNT TRANSISTOR |

| IMT4 | DUAL PNP SMALL SIGNAL SURFACE MOUNT TRANSISTOR |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| IMS-5SWD-65 | 制造商:VISHAY 制造商全稱:Vishay Siliconix 功能描述:Inductors |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。