- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄299186 > HSMS-280E-BLKG (AGILENT TECHNOLOGIES INC) SILICON, MIXER DIODE PDF資料下載

參數(shù)資料

| 型號: | HSMS-280E-BLKG |

| 廠商: | AGILENT TECHNOLOGIES INC |

| 元件分類: | 參考電壓二極管 |

| 英文描述: | SILICON, MIXER DIODE |

| 封裝: | LEAD FREE, SC-70, 3 PIN |

| 文件頁數(shù): | 7/10頁 |

| 文件大小: | 138K |

| 代理商: | HSMS-280E-BLKG |

6

TIME (seconds)

T

MAX

TEMPERATURE

(

°C)

0

50

100

150

200

250

60

Preheat

Zone

Cool Down

Zone

Reflow

Zone

120

180

240

300

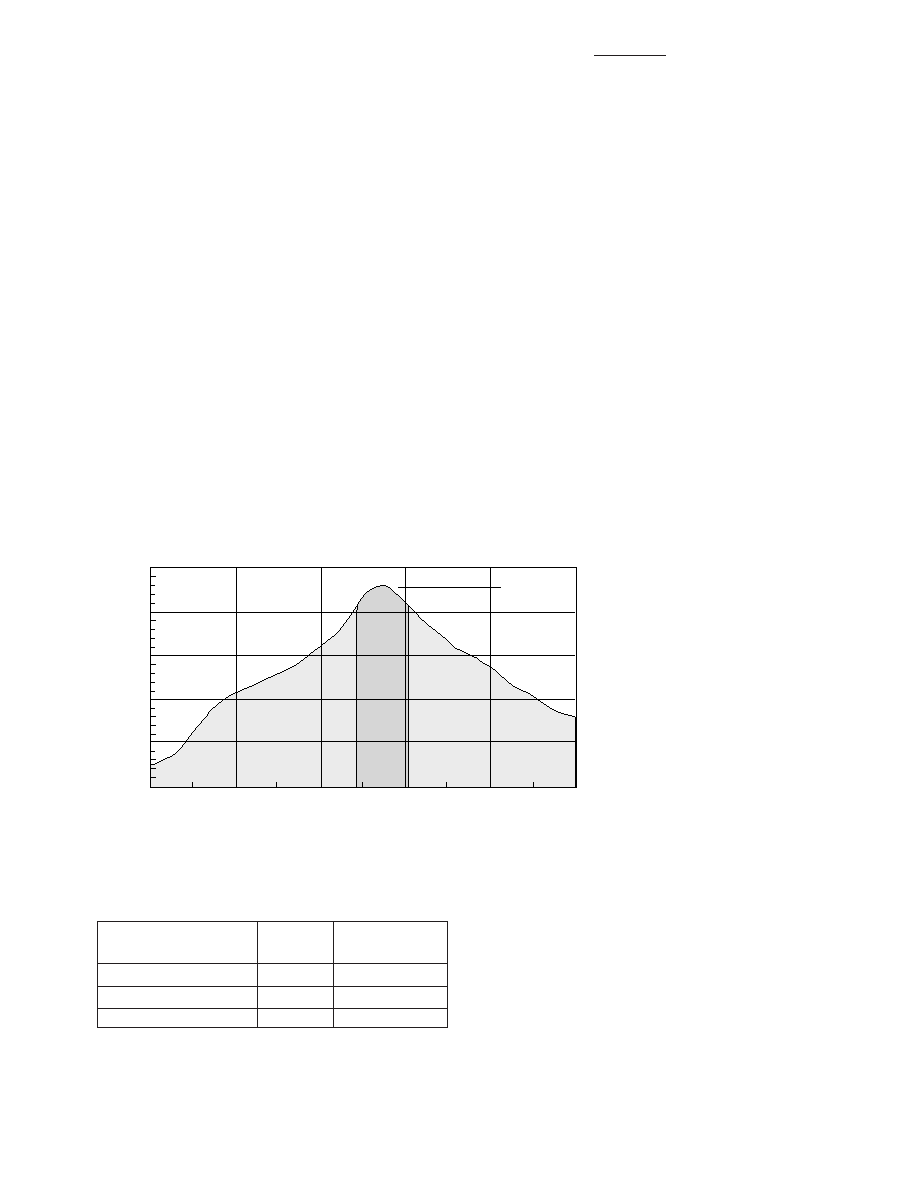

Figure 8. Surface Mount Assembly Profile.

SMT Assembly

Reliable assembly of surface

mount components is a complex

process that involves many

material, process, and equipment

factors, including: method of

heating (e.g., IR or vapor phase

reflow, wave soldering, etc.)

circuit board material, conductor

thickness and pattern, type of

solder alloy, and the thermal

conductivity and thermal mass of

components. Components with a

low mass, such as the SOT

package, will reach solder reflow

temperatures faster than those

with a greater mass.

The rates of change of tempera-

ture for the ramp-up and cool-

down zones are chosen to be low

enough to not cause deformation

of the board or damage to compo-

nents due to thermal shock. The

maximum temperature in the

reflow zone (TMAX) should not

exceed 235

°C.

These parameters are typical for a

surface mount assembly process

for Agilent diodes. As a general

guideline, the circuit board and

components should be exposed

only to the minimum tempera-

tures and times necessary to

achieve a uniform reflow of

solder.

Agilent’s SOT diodes have been

qualified to the time-temperature

profile shown in Figure 8. This

profile is representative of an IR

reflow type of surface mount

assembly process.

After ramping up from room

temperature, the circuit board

with components attached to it

(held in place with solder paste)

passes through one or more

preheat zones. The preheat zones

increase the temperature of the

board and components to prevent

thermal shock and begin evaporat-

ing solvents from the solder paste.

The reflow zone briefly elevates

the temperature sufficiently to

produce a reflow of the solder.

Part Number Ordering Information

No. of

Part Number

Devices

Container

HSMS-280x-TR2 *

10000

13" Reel

HSMS-280x-TR1 *

3000

7" Reel

HSMS-280x-BLK *

100

antistatic bag

x = 0, 2, 3, 4, 5, 7, 8, B, C, E, F, K, L, M, N, P, R

For lead-free option, the part number will have the

character "G" at the end, eg. HSMS-280x-TR2G for a

10,000 lead-free reel.

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| HSMS-2805L31 | SILICON, MIXER DIODE |

| HSMS-2803L31 | SILICON, MIXER DIODE |

| HSMS-2862L31 | SILICON, MIXER DIODE |

| HSMS-2807L31 | SILICON, MIXER DIODE |

| HSMS-2815 | SILICON, MIXER DIODE |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| HSMS-280E-TR1G | 功能描述:肖特基二極管與整流器 70 VBR 2 pF RoHS:否 制造商:Skyworks Solutions, Inc. 產(chǎn)品:Schottky Diodes 峰值反向電壓:2 V 正向連續(xù)電流:50 mA 最大浪涌電流: 配置:Crossover Quad 恢復時間: 正向電壓下降:370 mV 最大反向漏泄電流: 最大功率耗散:75 mW 工作溫度范圍:- 65 C to + 150 C 安裝風格:SMD/SMT 封裝 / 箱體:SOT-143 封裝:Reel |

| HSMS-280E-TR2G | 功能描述:肖特基二極管與整流器 70 VBR 2 pF RoHS:否 制造商:Skyworks Solutions, Inc. 產(chǎn)品:Schottky Diodes 峰值反向電壓:2 V 正向連續(xù)電流:50 mA 最大浪涌電流: 配置:Crossover Quad 恢復時間: 正向電壓下降:370 mV 最大反向漏泄電流: 最大功率耗散:75 mW 工作溫度范圍:- 65 C to + 150 C 安裝風格:SMD/SMT 封裝 / 箱體:SOT-143 封裝:Reel |

| HSMS-280F | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:Low reverse leakage Schottky diode |

| HSMS-280F-BLKG | 功能描述:肖特基二極管與整流器 70 VBR 2 pF RoHS:否 制造商:Skyworks Solutions, Inc. 產(chǎn)品:Schottky Diodes 峰值反向電壓:2 V 正向連續(xù)電流:50 mA 最大浪涌電流: 配置:Crossover Quad 恢復時間: 正向電壓下降:370 mV 最大反向漏泄電流: 最大功率耗散:75 mW 工作溫度范圍:- 65 C to + 150 C 安裝風格:SMD/SMT 封裝 / 箱體:SOT-143 封裝:Reel |

| HSMS-280F-TR1G | 功能描述:肖特基二極管與整流器 70 VBR 2 pF RoHS:否 制造商:Skyworks Solutions, Inc. 產(chǎn)品:Schottky Diodes 峰值反向電壓:2 V 正向連續(xù)電流:50 mA 最大浪涌電流: 配置:Crossover Quad 恢復時間: 正向電壓下降:370 mV 最大反向漏泄電流: 最大功率耗散:75 mW 工作溫度范圍:- 65 C to + 150 C 安裝風格:SMD/SMT 封裝 / 箱體:SOT-143 封裝:Reel |

發(fā)布緊急采購,3分鐘左右您將得到回復。