- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄375931 > FSCM0765R (Fairchild Semiconductor Corporation) Green Mode Fairchild Power Switch (FPS) PDF資料下載

參數(shù)資料

| 型號(hào): | FSCM0765R |

| 廠商: | Fairchild Semiconductor Corporation |

| 英文描述: | Green Mode Fairchild Power Switch (FPS) |

| 中文描述: | 綠色模式飛兆半導(dǎo)體功率開關(guān)(FPS) |

| 文件頁數(shù): | 10/20頁 |

| 文件大小: | 495K |

| 代理商: | FSCM0765R |

FSCM0765R

10

Functional Description

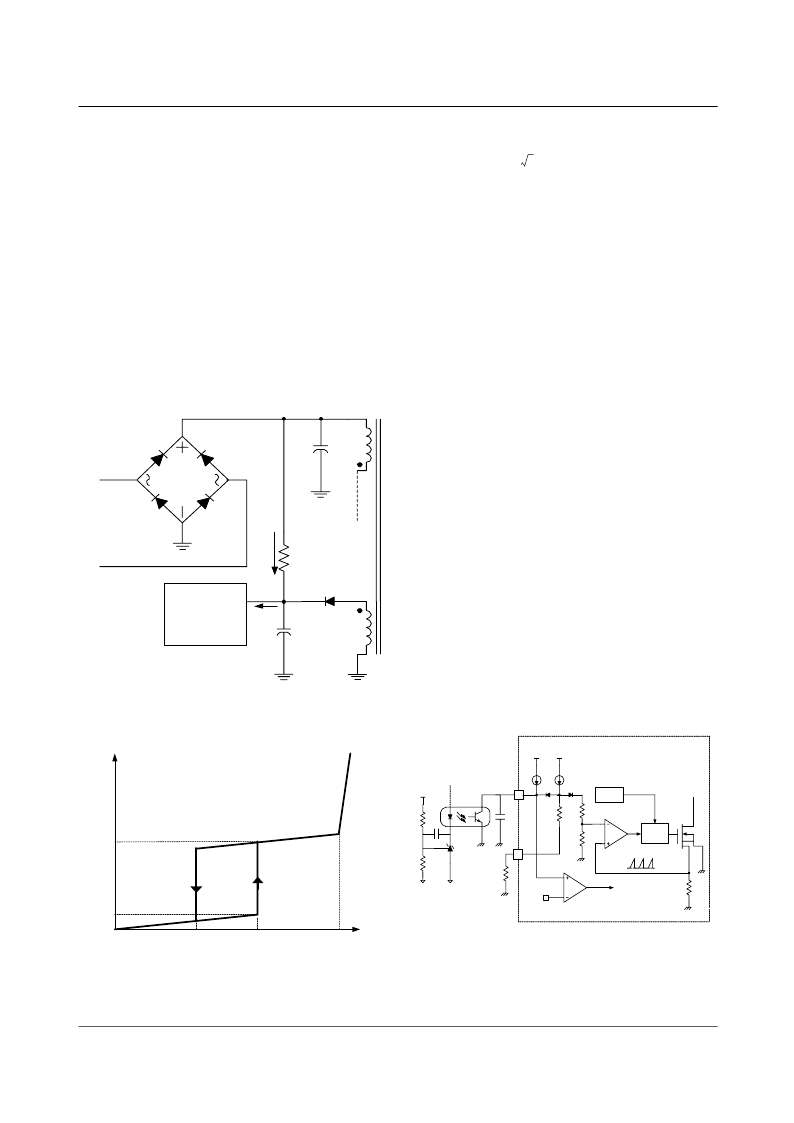

Startup

: Figure 16 shows the typical startup circuit and

transformer auxiliary winding for the FSCM0765R

application. Before the FSCM0765R begins switching, it

consumes only startup current (typically 25uA) and the

current supplied from the DC link supply current consumed

by the FPS (Icc), and charges the external capacitor (C

a

) that

is connected to the Vcc pin. When Vcc reaches start voltage

of 12V (V

START

), the

FSCM0765R begins switching, and the

current consumed by FSCM0765R increases to 3mA. Then,

the

FSCM0765R continues its normal switching operation

and the power required for this device is supplied from the

transformer auxiliary winding, unless Vcc drops below the

stop voltage of 8V (V

STOP

). To guarantee the stable operation

of the control IC, Vcc has under voltage lockout (UVLO)

with 4V hysteresis. Figure 17 shows the relation between the

current consumed by the

FPS (Icc) and the supply voltage

(Vcc).

1.

Figure 16. Startup Circuit

Figure 17. Relation Between O

perating Supply C

urrent

and Vcc Voltage

The minimum current supplied through the startup resistor is

given by

where

V

line

min

is the minimum input voltage,

V

start

is the

start voltage (12V) and

R

str

is the startup resistor. The startup

resistor should be chosen so that

I

sup

min

is larger than the

maximum startup current (40uA). If not, Vcc can not be

charged to the start voltage and FPS will fail to start up.

2. Feedback Control

: The

FSCM0765R employs current

mode control, as shown in Figure 18. An opto-coupler (such

as the H11A817A) and a shunt regulator (such as the

KA431) are typically used to implement the feedback

network. Comparing the feedback voltage with the voltage

across the Rsense resistor makes it possible to control the

switching duty cycle. When the reference pin voltage of the

KA431 exceeds the internal reference voltage of 2.5V, the

H11A817A LED current increases, thus pulling down the

feedback voltage and reducing the duty cycle. This event

typically happens when the input voltage is increased or the

output load is decreased.

2.1 Pulse-by-pulse Current Limit

: Because current mode

control is employed, the peak current through the SenseFET

is determined by the inverting input of the PWM comparator

(Vfb*) as shown in Figure 18. When the current through the

opto transistor is zero and the current limit pin (#5) is left

floating, the feedback current source (I

FB

) of 0.9mA flows

only through the internal resistor (R+2.5R=2.8k). In this

case, the cathode voltage of diode D2 and the peak drain

current have maximum values of 2.5V and 3A, respectively.

The pulse-by-pulse current limit can be adjusted using a

resistor to GND on the current limit pin (#5). The current

limit level using an external resistor (R

LIM

) is given by

:

Figure 18. Pulse Width Modulation (PWM) Circuit

FSCM0765R

Rstr

V

C C

Ca

Da

I

SUP

AC line

min

- V

line

(V

line

max

)

C

DC

I

C C

I

CC

V

CC

Vstop=8V

25uA

3mA

Vstart=12V

Vz

Power Up

Power Down

Isup

min

2 V

line

min

V

start

–

(

)

Rstr

=

I

LIM

R

3A

2.8k

Ω

+

R

LIM

------------------------------------

=

4

OSC

Vcc

Vref

I

delay

I

FB

V

SD

R

2.5R

Gate

driver

OLP

D1

D2

+

V

fb

*

-

Vfb

KA431

C

B

Vo

H11A817A

R

sense

SenseFET

6

R

LI M

0.9mA

0.3k

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| FSCM0765RC | Green Mode Fairchild Power Switch (FPS) |

| FSCM0765RD | Green Mode Fairchild Power Switch (FPS) |

| FSCM0565RC | Green Mode Fairchild Power Switch (FPS) |

| FSCM0565RD | Green Mode Fairchild Power Switch (FPS) |

| FSCM0765RGWDTU | Low Cost 200 MHz Differential Receiver Amplifier; Package: SOIC; No of Pins: 8; Temperature Range: Industrial |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| FSCM0765RC | 制造商:FAIRCHILD 制造商全稱:Fairchild Semiconductor 功能描述:Green Mode Fairchild Power Switch (FPS) |

| FSCM0765RCYDTU | 功能描述:電源開關(guān) IC - 配電 SMPS Power Switch RoHS:否 制造商:Exar 輸出端數(shù)量:1 開啟電阻(最大值):85 mOhms 開啟時(shí)間(最大值):400 us 關(guān)閉時(shí)間(最大值):20 us 工作電源電壓:3.2 V to 6.5 V 電源電流(最大值): 最大工作溫度:+ 85 C 安裝風(fēng)格:SMD/SMT 封裝 / 箱體:SOT-23-5 |

| FSCM0765RD | 功能描述:電源開關(guān) IC - 配電 SMPS Power Switch RoHS:否 制造商:Exar 輸出端數(shù)量:1 開啟電阻(最大值):85 mOhms 開啟時(shí)間(最大值):400 us 關(guān)閉時(shí)間(最大值):20 us 工作電源電壓:3.2 V to 6.5 V 電源電流(最大值): 最大工作溫度:+ 85 C 安裝風(fēng)格:SMD/SMT 封裝 / 箱體:SOT-23-5 |

| FSCM0765RG | 制造商:FAIRCHILD 制造商全稱:Fairchild Semiconductor 功能描述:Green Mode Fairchild Power Switch |

| FSCM0765RGWDTU | 功能描述:電源開關(guān) IC - 配電 SMPS POWER SWITCH POWER SWITCH GREEN RoHS:否 制造商:Exar 輸出端數(shù)量:1 開啟電阻(最大值):85 mOhms 開啟時(shí)間(最大值):400 us 關(guān)閉時(shí)間(最大值):20 us 工作電源電壓:3.2 V to 6.5 V 電源電流(最大值): 最大工作溫度:+ 85 C 安裝風(fēng)格:SMD/SMT 封裝 / 箱體:SOT-23-5 |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。