- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄299036 > EUS34-096-PHCRC (CD TECHNOLOGIES INC) 1-OUTPUT DC-DC REG PWR SUPPLY MODULE PDF資料下載

參數(shù)資料

| 型號(hào): | EUS34-096-PHCRC |

| 廠商: | CD TECHNOLOGIES INC |

| 元件分類: | 電源模塊 |

| 英文描述: | 1-OUTPUT DC-DC REG PWR SUPPLY MODULE |

| 封裝: | ROHS COMPLIANT, PACKAGE-5 |

| 文件頁數(shù): | 2/3頁 |

| 文件大?。?/td> | 517K |

| 代理商: | EUS34-096-PHCRC |

CDC_EUS34-096.A04 Page 2 of 3

EUS34-096

Isolated Bus Converter

P O W E R E L E C T R O N I C S D I V I S I O N

D C / D C C O N V E R T E R S

www.cd4power.com

Technical enquiries email: toronto@cdtechno.com, tel: (866) 740 232

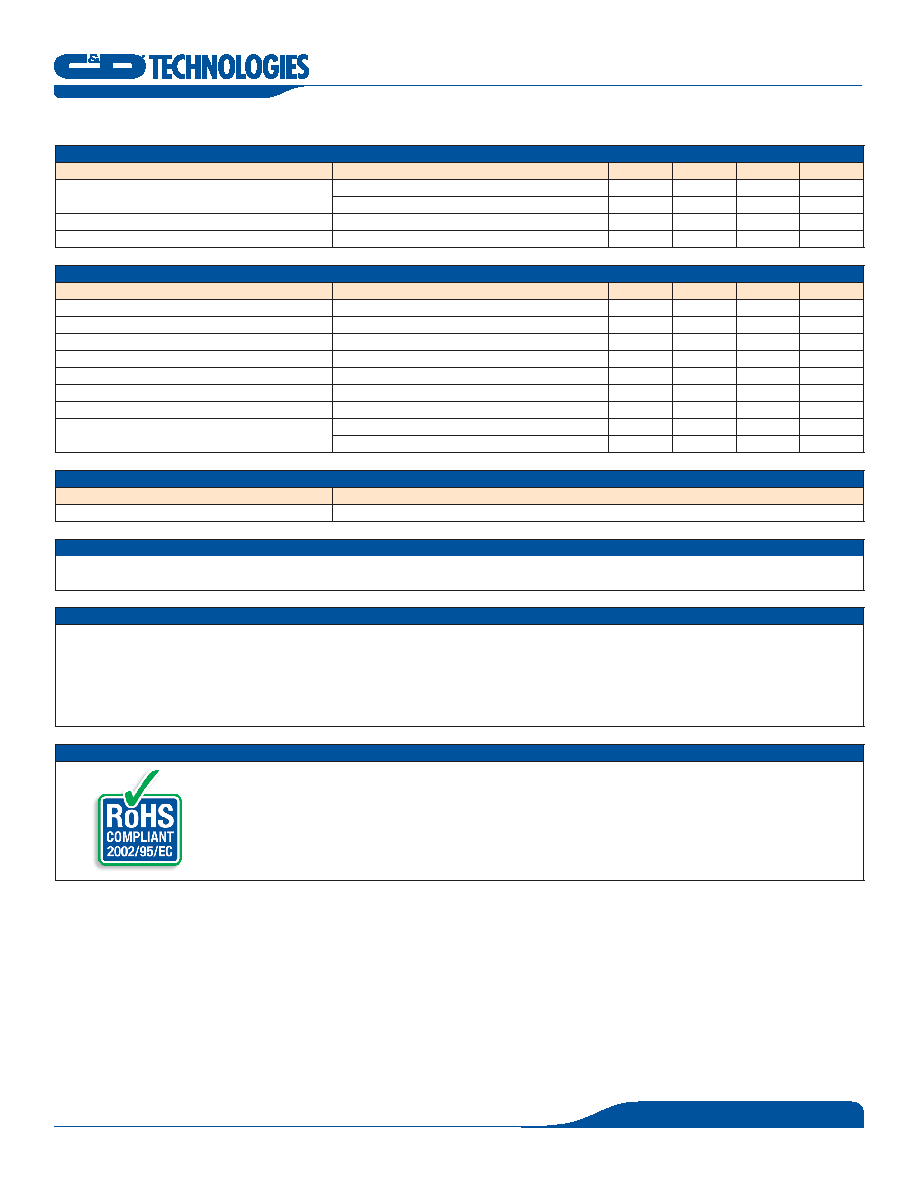

PROTECTION CHARACTERISTICS

Parameter

Conditions

Min.

Typ.

Max.

Units

Output over-current shutdown2

Auto-restart

38

40

42

A

Re-start rate

TBD

ms

Over temperature shutdown3

Auto-restart

35

40

C

Over temperature restart hysteresis

0

C

GENERAL CHARACTERISTICS

Parameter

Conditions

Min.

Typ.

Max.

Units

Isolation voltage

Input to output

2250

VDC

Isolation resistance

Input to output

0

MΩ

Storage temperature range

Non-condensing

-40

25

C

Operating temperature range

-40

85

C

Operating humidity

Non-condensing

0

90

%

Thermal measurement location temperature3

See mechanical drawing for location

30

C

Material flammability

UL 94V-0

MTBF

Calculated per Mil Spec 27 E, or Bellcore at Ta=30C

2

x06 Hrs

Demonstrated

.3

x06 Hrs

STANDARDS COMPLIANCE

Standards

Conditions4

UL/CSA 60950

Basic insulation

MANUFACTURING TESTING

nBurn-in test

nParametric test

SAFETY CONSIDERATIONS

This series of converters are certified to the standards and extent listed in the ‘Standards Compliance’ section in the table above. If this product is built into

information technology equipment, the installation must comply with the above standard. Even though the product is safety certified to operate without an input

fuse, it is recommended that an input fuse of 2A (max.) is used.

The output of the converter (Vo+/Vo-) is considered to remain within SELV limits when the input to the converter meets SELV or TNV-2 requirements. The

converters and materials meet UL 94V-0 flammability ratings.

RoHS COMPLIANCE

The EUS34-096 converter is in compliance with the European Union Directive 2002/95/EC (RoHS) with respect to the

following substances: lead (Pb), cadmium (Cd), mercury (Hg), hexavalent chromium, polybrominated biphenyls (PBB) and

polybrominated diphenyl ethers (PBDE).

For further information, please visit www.cd4power.com/rohs

VIN = 48Vdc, Ta = 25C, Airflow = 200 LFM for all data unless otherwise noted.

2 Input transient: if input voltage increases by 5V in s, output over-current shut-down shall not be triggered (tested with Max. load and Max. output capacitance).

3 Thermal shutdown is monitored at the Thermal Measurement Location (TML). See ‘Mechanical Information’ on page 3 for TML location.

4 See ‘Safety Considerations’ shown on page 4.

Derating curves are conducted in a controlled environment. End application testing is required to ensure the Thermal Measurement Location temperature is below the maximum specified.

Recommended airflow direction is from pin to pin 3, or 3 to (transversal to the unit).

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| EW930092-00 | FEMALE-FEMALE, RF STRAIGHT ADAPTER, JACK |

| EW930092-20 | MALE-FEMALE, RF STRAIGHT ADAPTER, PLUG-JACK |

| EW940021-00 | MALE-FEMALE, RF STRAIGHT ADAPTER, PLUG-JACK |

| EW940021-10 | PANEL MOUNT, FEMALE-FEMALE, RF STRAIGHT ADAPTER |

| EW940021-20 | FEMALE-FEMALE, RF STRAIGHT ADAPTER, JACK |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| EUS34-096-PHCRVC | 制造商:MURATA-PS 制造商全稱:Murata Power Solutions Inc. 功能描述:Isolated Bus Converter |

| EUS-44-01455 | 制造商:EAO International 功能描述:PB/IL/MO/LED/1/1/RE/G |

| EUS-44-02255 | 制造商:EAO International 功能描述:PB/IL/MA/LED/1/1/FR/G |

| EUS-44-06552 | 制造商:EAO International 功能描述:EST/TWS.R/MA/1/1/FR |

| EUS-44-06562 | 制造商:EAO International 功能描述:EST/TWS.R/MA/2/2/FR |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。