- 您現(xiàn)在的位置:買賣IC網 > PDF目錄223658 > DME3936-000 (SKYWORKS SOLUTIONS INC) SILICON, MEDIUM BARRIER SCHOTTKY, S BAND, MIXER DIODE PDF資料下載

參數(shù)資料

| 型號: | DME3936-000 |

| 廠商: | SKYWORKS SOLUTIONS INC |

| 元件分類: | 射頻混頻器 |

| 英文描述: | SILICON, MEDIUM BARRIER SCHOTTKY, S BAND, MIXER DIODE |

| 封裝: | GREEN, DIE-4 |

| 文件頁數(shù): | 3/6頁 |

| 文件大小: | 456K |

| 代理商: | DME3936-000 |

Data Sheet Silicon BeamleSS Schottky DioDeS

Skyworks Solutions, Inc. Phone [781] 376-3000 Fax [781] 376-3100 sales@skyworksinc.com www.skyworksinc.com

200793 Rev. B Skyworks Proprietary Information Products and Product Information are Subject to Change Without Notice. December 18, 2008

3

characteristic

Value

TSTG

-65 °C to +175 °C

TOP

-65 °C to +150 °C

PDISS CW

75 mW/junction

IMAX

50 mA V

PIV

VB rating

Absolute Maximum Ratings

Performance is guaranteed only under the conditions listed in the specifications table and is

not guaranteed under the full range(s) described by the Absolute Maximum Ratings. Exceeding

any of the absolute maximum/minimum specifications may result in permanent damage to the

device and will void the warranty.

CAUTION: Although these devices are designed to be robust, ESD

(Electrostatic Discharge) can cause permanent damage.

Static charges may easily produce potentials of several

kilovolts on the human body or equipment, which can

discharge without detection. Industry-standard ESD

precautions must be employed at all times.

Assembly and Handling Procedure

The process flow for assembly is:

1. Die attach using nonconductive epoxy

2. Wire bond

3. Encapsulation—nonconductive epoxy

Die Attach Methods

All leadless chips are compatible with both eutectic and conduc-

tive epoxy die attach methods. Eutectic processes use Sn/Au or

Sn/Pb solder. Nonconductive die attach is recommended.

Packing Methods

1. Vacuum release gel pack.

2. Wafer on film frame (rejects are marked with ink).

– Diced, ready for pick and place

– Unsawn whole wafer, 7 mil thick, max.

Wire Bonding

Two methods can be used to connect wire, ribbon, or wire mesh

to the chips:

l

Thermocompression

l

Ballbonding

Skyworks recommends use of pure gold wire

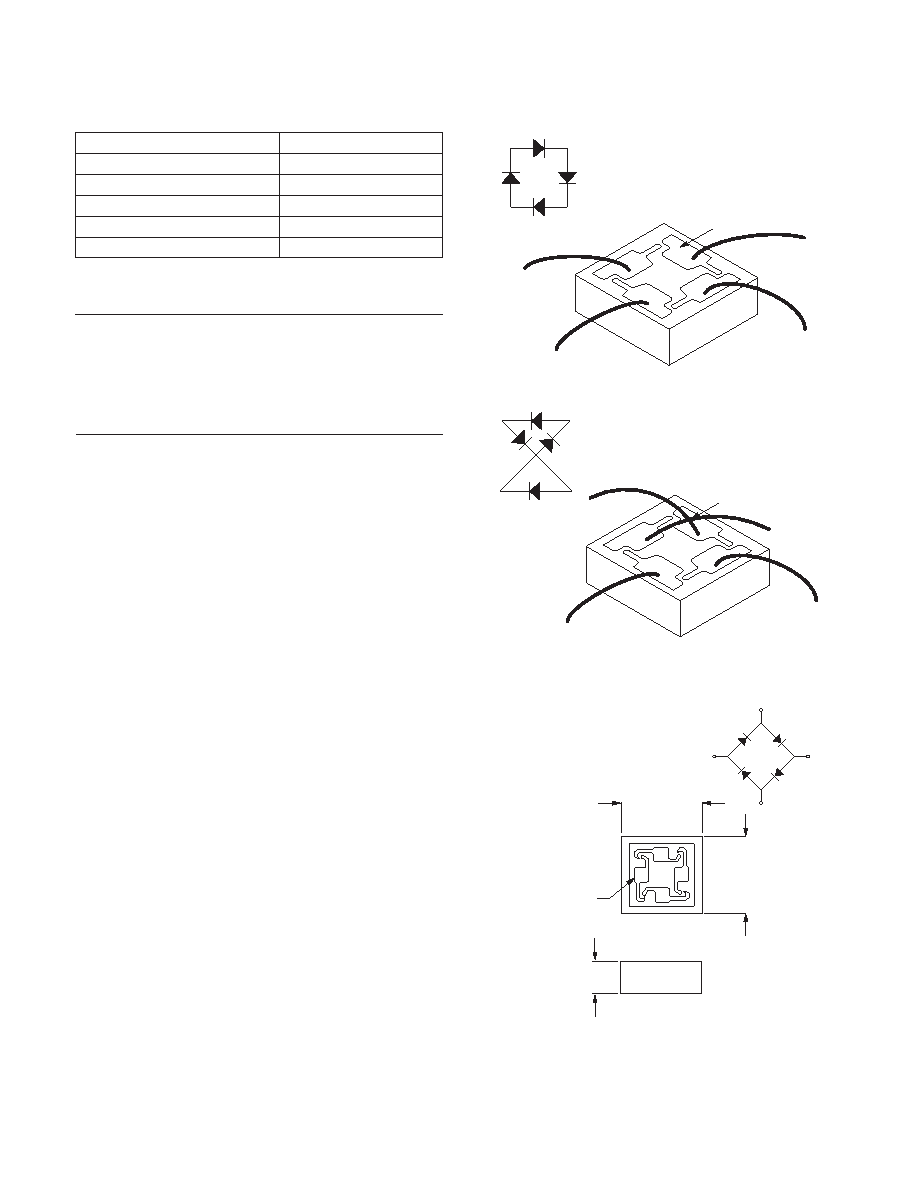

Typical Bonding Configuration

Ring Quad

Crossover Quad

Bond Pad

13

24

13

24

Bond Pad

551-002

0.015 (0.381 mm)

± 0.001 (0.025 mm)

0.015 (0.381 mm)

± 0.001 (0.025 mm)

3

2

4

1

0.0035 (0.089 mm)

± 0.0035 (0.089 mm)

4 Plcs.

Schematic

0.006 (0.18 mm)

± 0.001 (0.025 mm)

13

2

4

相關PDF資料 |

PDF描述 |

|---|---|

| DME3939-000 | SILICON, MEDIUM BARRIER SCHOTTKY, S-X BAND, MIXER DIODE |

| DME3936-551-056 | SILICON, MEDIUM BARRIER SCHOTTKY, S BAND, MIXER DIODE |

| DMF3935-551-056 | SILICON, LOW BARRIER SCHOTTKY, S BAND, MIXER DIODE |

| DMJ3937-551-056 | SILICON, HIGH BARRIER SCHOTTKY, S BAND, MIXER DIODE |

| DMF3948-106 | SILICON, LOW BARRIER SCHOTTKY, X BAND, MIXER DIODE |

相關代理商/技術參數(shù) |

參數(shù)描述 |

|---|---|

| DME3939-000 | 制造商:Skyworks Solutions Inc 功能描述:RF SCHOTTKY DIODE |

| DME3939-257 | 制造商:Skyworks Solutions Inc 功能描述:RF SCHOTTKY DIODE |

| DME3943-000 | 制造商:Skyworks Solutions Inc 功能描述:RF SCHOTTKY DIODE |

| DME3946 | 制造商:ALPHA 制造商全稱:ALPHA 功能描述:Chip On Board Mixer Quads |

| DME3946-000 | 制造商:Skyworks Solutions Inc 功能描述:RF SCHOTTKY DIODE |

發(fā)布緊急采購,3分鐘左右您將得到回復。