- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄298987 > DDW1046 DC-DC REG PWR SUPPLY MODULE PDF資料下載

參數(shù)資料

| 型號: | DDW1046 |

| 元件分類: | 電源模塊 |

| 英文描述: | DC-DC REG PWR SUPPLY MODULE |

| 封裝: | PLASTIC, DIP-6/16 |

| 文件頁數(shù): | 5/8頁 |

| 文件大小: | 274K |

| 代理商: | DDW1046 |

5

Design & Feature Considerations

Maximum Capacitive Load

The DDW1000 series has limitation of maximum

connected capacitance at the output. The power

module may be operated in current limiting mode

during start-up, affecting the ramp-up and the startup

time. The maximum allowed capacitive load is listed in

table on page 2.

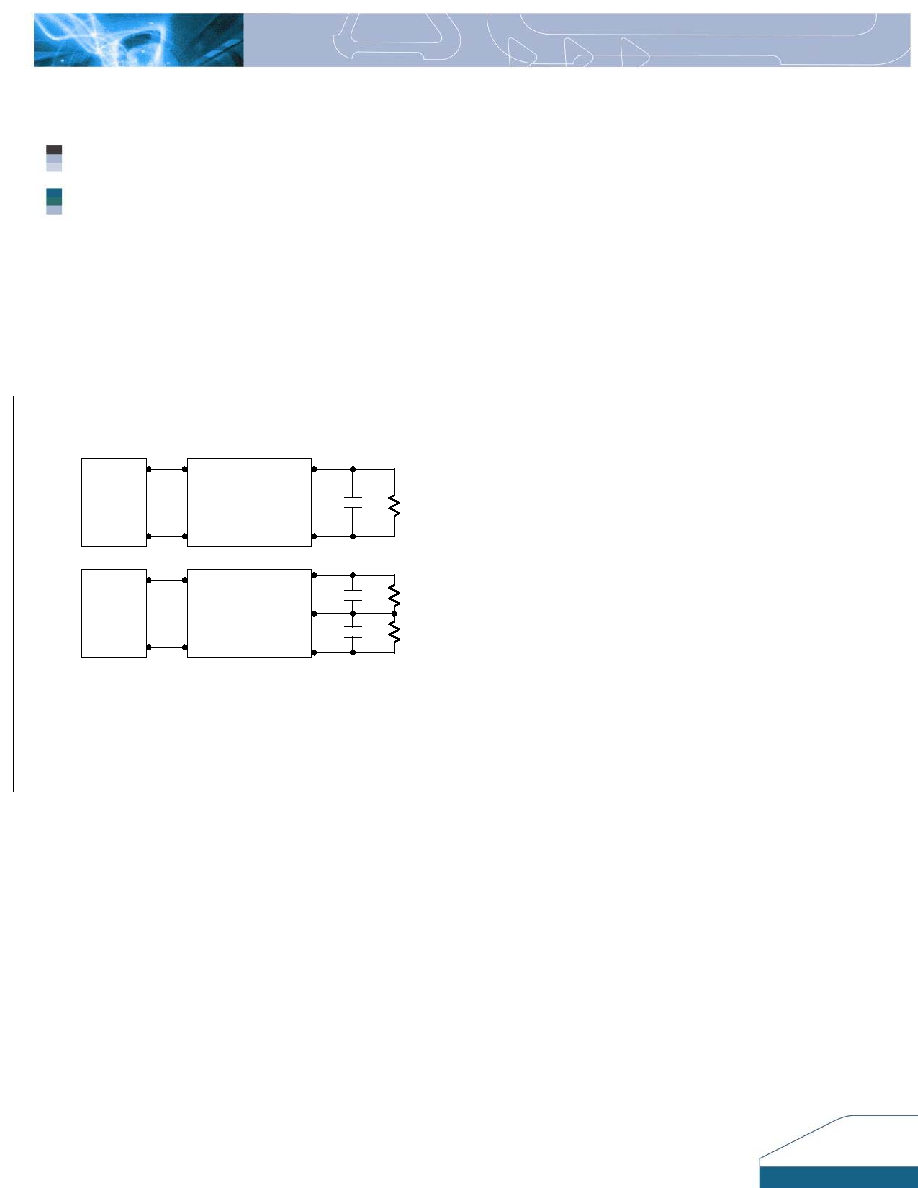

Output Ripple Reduction

A good quality low ESR capacitor placed as close as

practicable across the load will give the best ripple and

noise performance.

To reduce output ripple, it is recommended to use

3.3uF capacitors at the output.

+Out

-Out

+Vin

-Vin

Load

DC Power

Source

+

-

Cout

Single Output

DC / DC

Converter

+Out

-Out

+Vin

-Vin

Load

DC Power

Source

+

-

Cout

Com.

Dual Output

DC / DC

Converter

Overcurrent Protection

To provide protection in a fault (output overload) condition,

the unit is equipped with internal current limiting circuitry

and can endure current limiting for an unlimited duration.

At the point of current-limit inception, the unit shifts from

voltage control to current control. The unit operates

normally once the output current is brought back into its

specified range.

Soldering and Cleaning Considerations

Post solder cleaning is usually the final board assembly

process before the board or system undergoes electrical

testing. Inadequate cleaning and/or drying may lower the

reliability of a power module and severely affect the

finished circuit board assembly test. Adequate cleaning

and/or drying is especially important for un-encapsulated

and/or open frame type power modules. For assistance

on appropriate soldering and cleaning procedures,

please contact Delta’s technical support team.

Notes:

1. These power converters require a minimum output load

to maintain specified regulation (please see page 6 for

the suggested minimum load). Operation under no-load

conditions will not damage these modules; however,

they may not meet all specifications listed above.

2. These DC/DC converters should be externally fused at

the front end for protection.

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| DDW1021 | DC-DC REG PWR SUPPLY MODULE |

| DDW1024 | DC-DC REG PWR SUPPLY MODULE |

| DDW1043 | DC-DC REG PWR SUPPLY MODULE |

| DDW1045 | DC-DC REG PWR SUPPLY MODULE |

| DDW1036 | DC-DC REG PWR SUPPLY MODULE |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| DDW-CJD-R1 | 制造商:DOMINANT 制造商全稱:DOMINANT Semiconductors 功能描述:LED InGaN White |

| DDW-CJD-R2 | 制造商:DOMINANT 制造商全稱:DOMINANT Semiconductors 功能描述:LED InGaN White |

| DDW-CJD-RS2-1 | 制造商:DOMINANT 制造商全稱:DOMINANT Semiconductors 功能描述:LED InGaN White |

| DDW-CJD-S1 | 制造商:DOMINANT 制造商全稱:DOMINANT Semiconductors 功能描述:LED InGaN White |

| DDW-CJD-S2 | 制造商:DOMINANT 制造商全稱:DOMINANT Semiconductors 功能描述:LED InGaN White |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。