- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄376528 > D370 (Lineage Power) Digital Uncooled DFB(distributed-feedback) Laser Module(數(shù)字常溫DFB(分布式反饋)激光模塊) PDF資料下載

參數(shù)資料

| 型號(hào): | D370 |

| 廠商: | Lineage Power |

| 英文描述: | Digital Uncooled DFB(distributed-feedback) Laser Module(數(shù)字常溫DFB(分布式反饋)激光模塊) |

| 中文描述: | 數(shù)字非致冷激光器(分布反饋)激光模組(數(shù)字常溫足協(xié)(分布式反饋)激光模塊) |

| 文件頁(yè)數(shù): | 2/8頁(yè) |

| 文件大小: | 175K |

| 代理商: | D370 |

Data Sheet

October 2000

D370-Type Digital Uncooled

FastLight

Laser Module

2

Lucent Technologies Inc.

Description

(continued)

The device characteristics listed in this document are

met at 1.0 mW output power. Higher- or lower-power

operation is possible. Under conditions of a fixed pho-

todiode current, the change in optical output is typically

±

0.5 dB over an operating temperature range of –40

to +85

°

C.

°

C

This device incorporates the new laser 2000 manufac-

turing process from the Optoelectronic Products unit of

Lucent Technologies Microelectronics Group. Laser

2000 is a low-cost platform that targets high-volume

manufacturing and tight product distributions on all

optical subassemblies. This platform incorporates an

advanced optical design that is produced on Lucent’s

highly automated production lines. The laser 2000 plat-

form is qualified for the central office and uncontrolled

environments, and can be used for applications requir-

ing high performance and low cost.

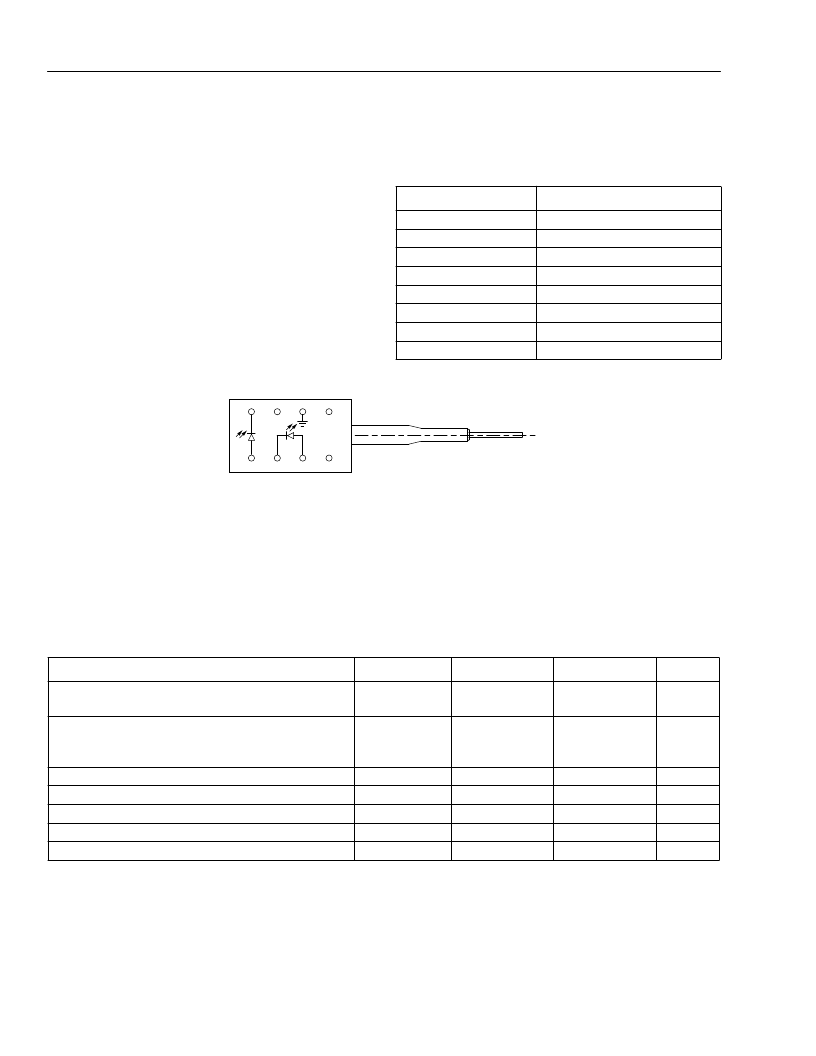

Table 1. Pin Descriptions

Pin Number

1

2

3

4

5

6

7

8

Connection

NC/Reserved

Case ground

NC/Reserved

Photodiode cathode

Photodiode anode

Laser diode cathode

Laser diode anode

NC/Reserved

Figure 1. D370-Type Digital Uncooled Laser Module Schematic, Top View

Absolute Maximum Ratings

Stresses in excess of the absolute maximum ratings can cause permanent damage to the device. These are abso-

lute stress ratings only. Functional operation of the device is not implied at these or any other conditions in excess

of those given in the operations sections of the data sheet. Exposure to absolute maximum ratings for extended

periods can adversely affect device reliability.

* Rating varies with temperature.

Parameter

Symbol

I

OP

P

MAX

Min

—

—

Max

150

10

Unit

mA

mW

Maximum Peak Laser Drive Current or

Maximum Fiber Power

Peak Reverse Laser Voltage:

Laser

Monitor

Monitor Forward Current

Operating Case Temperature Range

Storage Case Temperature Range

Lead Soldering Temperature/Time

Relative Humidity (noncondensing)

*

V

V

I

T

T

—

RH

RL

RD

—

—

—

–40

–40

—

—

2

20

2

85

85

V

V

FD

mA

°

C

°

C

°

C/s

%

C

stg

260/10

85

1-900

5

6

8

7

4

3

1

2

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| D371A | EL Drivers(EL驅(qū)動(dòng)器) |

| D371A | Electroluminescent Lamp Driver IC |

| D371 | Digital Uncooled DFB(distributed-feedback) Laser Module(數(shù)字常溫DFB(分布式反饋)激光模塊) |

| D372-21GS | D372-Type Digital Uncooled DFB Laser Module for 2.5 Gbits/s Applications |

| D372-21SS | D372-Type Digital Uncooled DFB Laser Module for 2.5 Gbits/s Applications |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| D-370 | 制造商:Triad Magnetics 功能描述: |

| D37000J00 | 制造商:Positronic Industries 功能描述: |

| D37000Y00 | 制造商:POSTITRONICS 功能描述:CONNECTOR HOLDERS 制造商:MIL 功能描述: 制造商:N/A 功能描述: |

| D37000Z00 | 制造商:POSITR 功能描述: 制造商:Positronic Industries 功能描述: |

| D370-02A | 制造商:AGERE 制造商全稱:AGERE 功能描述:D370-Type Digital Uncooled Laser Module |

發(fā)布緊急采購(gòu),3分鐘左右您將得到回復(fù)。