- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄369387 > B64290L674X830 CORE 36X23X15 N30 PDF資料下載

參數(shù)資料

| 型號: | B64290L674X830 |

| 英文描述: | CORE 36X23X15 N30 |

| 中文描述: | 共有n30核心36X23X15 |

| 文件頁數(shù): | 1/21頁 |

| 文件大?。?/td> | 241K |

| 代理商: | B64290L674X830 |

Siemens Matsushita Components

587

G

Our product line includes a wide range of ring cores with finely graded diameters ranging from

2,5 to 200 mm (see overview of available types). Other core heights can be supplied on request.

All cores are available in the usual materials.

Ring cores are available in different coating versions, thus offering the appropriate solution for

every application. The coating not only offers protection for the edges but also provides an

insulation function.

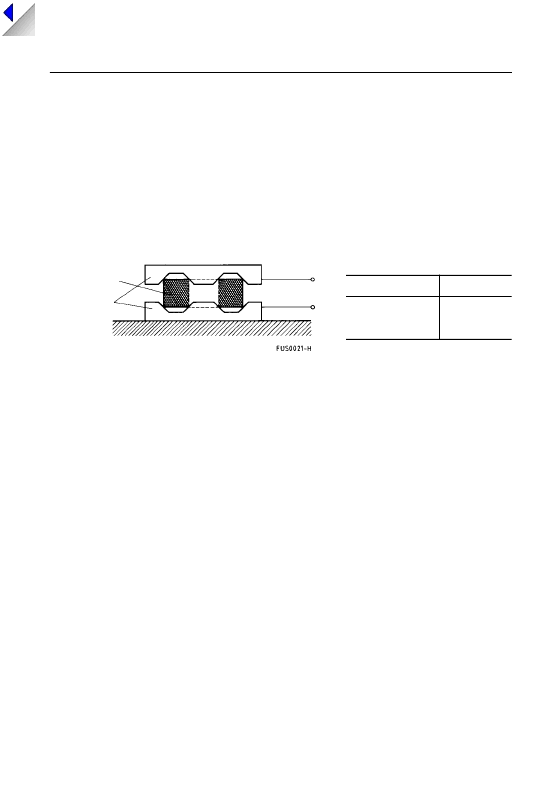

The following test setup is used to test the dielectric strength of the insulating coating: A copper

ring is pressed to the top edge of the ring. It touches the ferrite ring at the edges (see diagram).

The test duration is 2 seconds; the test voltages specified in the table are minimum values for

epoxy- and Rilsan-coated cores:

For cores with high permeability, increased spread of the A

L

values of several percent must be ex-

pected according to the specifications due to the Polyamid coating process. This effect can be

avoided by using an epoxy resin coating (L version).

For small ring cores, we have introduced a parylene coating (Galxyl) which features a low coating

thickness and high dielectric strength.

G

Ring cores are used primarily for pulse and broadband transformers, baluns and chokes. Owing

to the magnetically closed circuit, high flux densities can be achieved at small volume. Magnetic

leakage is negligible.

G

Ring cores are also increasingly used for power applications. Here, the typical values for ampli-

tude permeability and power loss, as summarized in the section on SIFERRIT materials

(page

33

), are applicable to the special power materials.

G

Characteristic data for cores not included among the preferred types are available on request.

Core size

U

rms

1,0 kV

1,5 kV

2,0 kV

R 4 thru R 10

R 12,5 thru R 20

> R 20

Ferrite ring

Metal poles

U

rms

Ring Cores

General Information

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| B64G-NNK-AD3-RMN | FILTER REGLER ENTLEER AUTOM 0.5ZOLL |

| B64G-NNK-MD3-RMN | "FILTER/REGULATOR MANUAL G1/2""" |

| B65808E1508T1 | FORMER RM6 POWER APP |

| B65803PR87 | CORE RM4 N87 MAT |

| B65804B6010T1 | CORE RM4 J TERM |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| B64290-L674-X830 | 制造商:EPCOS 功能描述:Bulk |

| B64290L674X830 | 制造商:TDK-EPC 功能描述:RING CORE 36X23X15 N30 |

| B64290L674X87 | 制造商:TDK Epcos 功能描述: 制造商:TDK Epcos 功能描述:FERRITE CORES |

| B64290L681X46 | 功能描述:EMI/RFI 抑制器及鐵氧體 TOROID9,53X4,75X2T46 RoHS:否 制造商:Fair-Rite 產(chǎn)品:Ferrite Cores 阻抗:365 Ohms 容差: 最大直流電流: 最大直流電阻: 工作溫度范圍:- 55 C to + 125 C 封裝 / 箱體: 端接類型:SMD/SMT |

| B64290L690X38 | 功能描述:FERRITE CORE 制造商:epcos (tdk) 系列:B64290 零件狀態(tài):有效 標(biāo)準(zhǔn)包裝:2,000 |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。