- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄295121 > AXS10TQ22 DIP10, IC SOCKET PDF資料下載

參數(shù)資料

| 型號: | AXS10TQ22 |

| 元件分類: | 插座 |

| 英文描述: | DIP10, IC SOCKET |

| 封裝: | ROHS COMPLIANT |

| 文件頁數(shù): | 2/2頁 |

| 文件大小: | 107K |

| 代理商: | AXS10TQ22 |

IC

sockets

AXS1

SPECIFICATIONS

1. Characteristics

2. Material and surface treatment

Recommended PC board thickness: 1.6mm

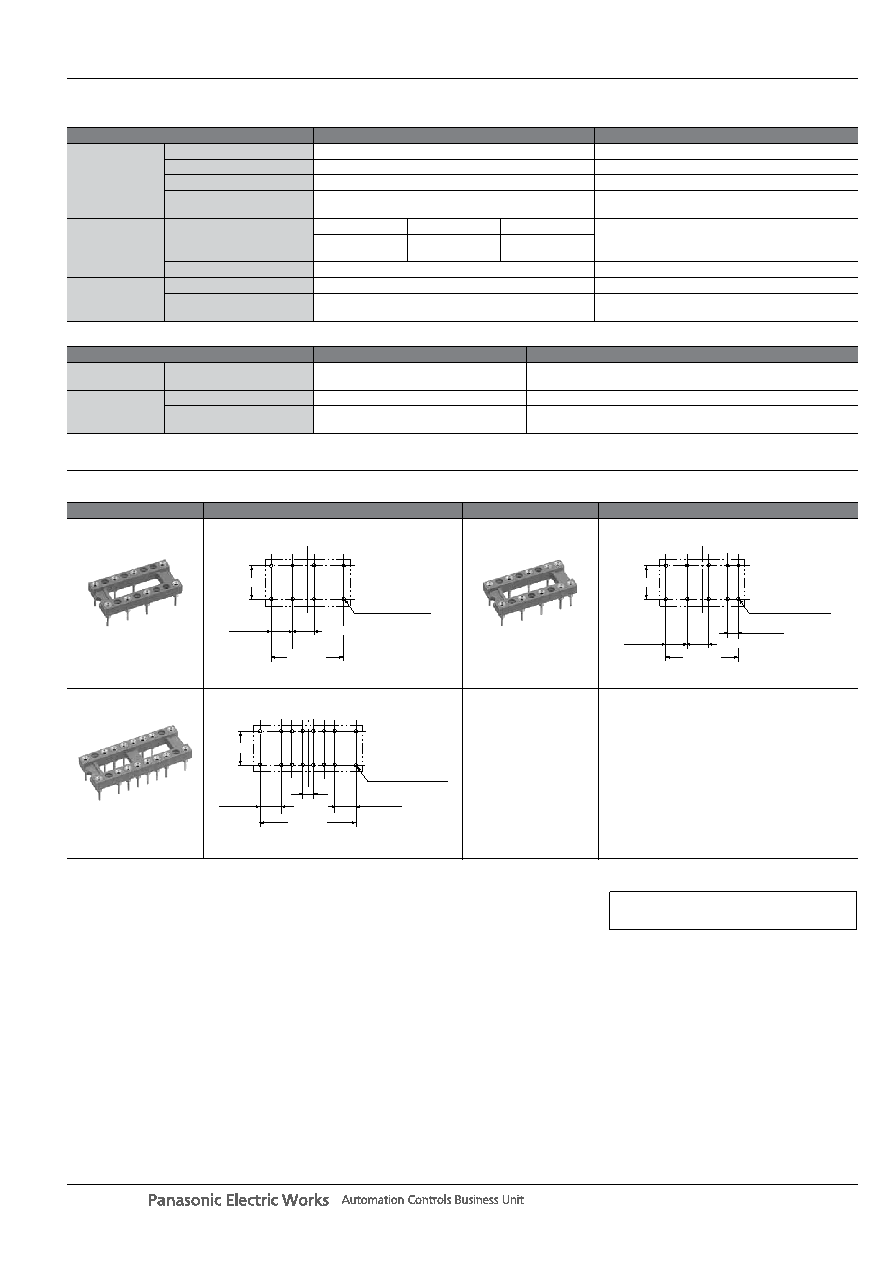

PC BOARD PATTERN (Unit: mm)

NOTES

Item

Specications

Condition

Electrical

characteristics

Rated current

2A

Breakdown voltage

1,000V AC for 1 min.

Detection current: 1mA

Insulation resistance

Min. 1,000M

Using 500V DC megger

Contact resistance

Max. 20m

Measured based on the HP4338B measurement

method of JIS C 5402

Mechanical

characteristics

Composite insertion force

AXS10DS21

AXS10DS22

AXS10TQ41

—

Max. 56.4N

{5.75kgf}

Max. 70.5N

{7.19kgf}

Max. 70.6N

{7.20kgf}

Holding force of a pin

Max. 19.6N {2.0kgf}

—

Environmental

characteristics

Ambient temperature

–55 to +125

°C (not applied to relays)

No freezing at low temperature, Max. 85% R.H.

Soldering heat resistance

260

°C within 10 sec.

Soldering iron tip 350

°C within 3 sec.

Soldering bath

Soldering iron

Part name

Material

Surface treatment

Molded poration

Frame

Glass reinforced PBT

(UL94V-0)

—

Metal poration

External sleeve

Brass

Ni plating on base, Sn plating on surface

Internal contact

Beryllium copper

Ni plating on base, Au plating on surface (0.25

m)

For TQ Relay 4 Form C: Au (0.76

m) plating

Part No.

Pattern (Bottom view)

Part No.

Pattern (Bottom view)

AXS10DS21

Dimension is same as

16 contacts, round pin type

IC socket.

AXS10DS22

Dimension is same as

16 contacts, round pin type

IC socket.

AXS10TQ41

Dimension is same as

20 contacts, round pin type

IC socket.

7.62

±0.1

5.08

±0.05

17.78

±0.1

8-0.8

±0.05 dia. hole

5.08

±0.05

7.62

±0.1

5.08

±0.05

17.78

±0.1

10-0.8

±0.05 dia. hole

5.08

±0.05

2.54

±0.05

7.62

±0.1

5.08

±0.05

22.86

±0.1

16-0.8

±0.05 dia. hole

5.08

±0.05

2.54

±0.05

1. Pre-soldering the relay terminals will

make the terminals thicker so that it may

not be possible to insert them into the

socket.

2. These sockets cannot be used for self-

standing relays whose terminals are bent

in places.

3. Do not insert leads which exceed the

suitable dimensions. Otherwise, the

internal contacts may be bent out of

shape.

4. Repeated bending of the terminals can

cause breakage. Take extra care when

handling.

5. Soldering should be carried out under

the following conditions.

260

°C: within 10 seconds

300

°C: within 5 seconds

350

°C: within 3 seconds

6. Care should be exercised at the

assembly stage since these sockets do

not come with a function for preventing

the reverse assembly of the relays.

For other details, please verify with

the product specication sheets.

panasonic-electric-works.net/ac

相關PDF資料 |

PDF描述 |

|---|---|

| AXS10TQ41 | DIP16, IC SOCKET |

| AXS4642N1K | QFP64, IC SOCKET |

| AXS4802N1 | QFP80, IC SOCKET |

| AY03L | 3400 MHz - 3500 MHz RF/MICROWAVE 90 DEGREE HYBRID COUPLER, 0.3 dB INSERTION LOSS-MAX |

| AY1101F-TR | SINGLE COLOR LED, YELLOW, 2 mm |

相關代理商/技術參數(shù) |

參數(shù)描述 |

|---|---|

| AXS-1147-02-02 | 功能描述:測試插座 Crystal Test & Burn-In Socket RoHS:否 制造商:Deltron |

| AXS-1155-04-01 | 功能描述:SOCKET 4PAD 11.8X5.5 CRYSTAL RoHS:是 類別:晶體和振蕩器 >> 插口和絕緣體 系列:- 產(chǎn)品目錄繪圖:CI-148-028-3 (SR) 標準包裝:100 系列:- 類型:絕緣體 適用于相關產(chǎn)品:晶體 位置數(shù):3 設備尺寸:HC-80/U 其它名稱:492-1038CI-148-028-3 SR |

| AXS-16-26 | 制造商:Middle Atlantic Products 功能描述: |

| AXS-17-26 | 制造商:Middle Atlantic Products 功能描述: |

| AXS-17-26-GG | 制造商:Middle Atlantic Products 功能描述: |

發(fā)布緊急采購,3分鐘左右您將得到回復。