- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄298491 > 711-17E24-12SF(416) (AMPHENOL CORP) 12 CONTACT(S), FEMALE, CIRCULAR CONNECTOR, CRIMP, RECEPTACLE PDF資料下載

參數(shù)資料

| 型號: | 711-17E24-12SF(416) |

| 廠商: | AMPHENOL CORP |

| 元件分類: | 圓形連接器 |

| 英文描述: | 12 CONTACT(S), FEMALE, CIRCULAR CONNECTOR, CRIMP, RECEPTACLE |

| 文件頁數(shù): | 12/12頁 |

| 文件大小: | 631K |

| 代理商: | 711-17E24-12SF(416) |

9

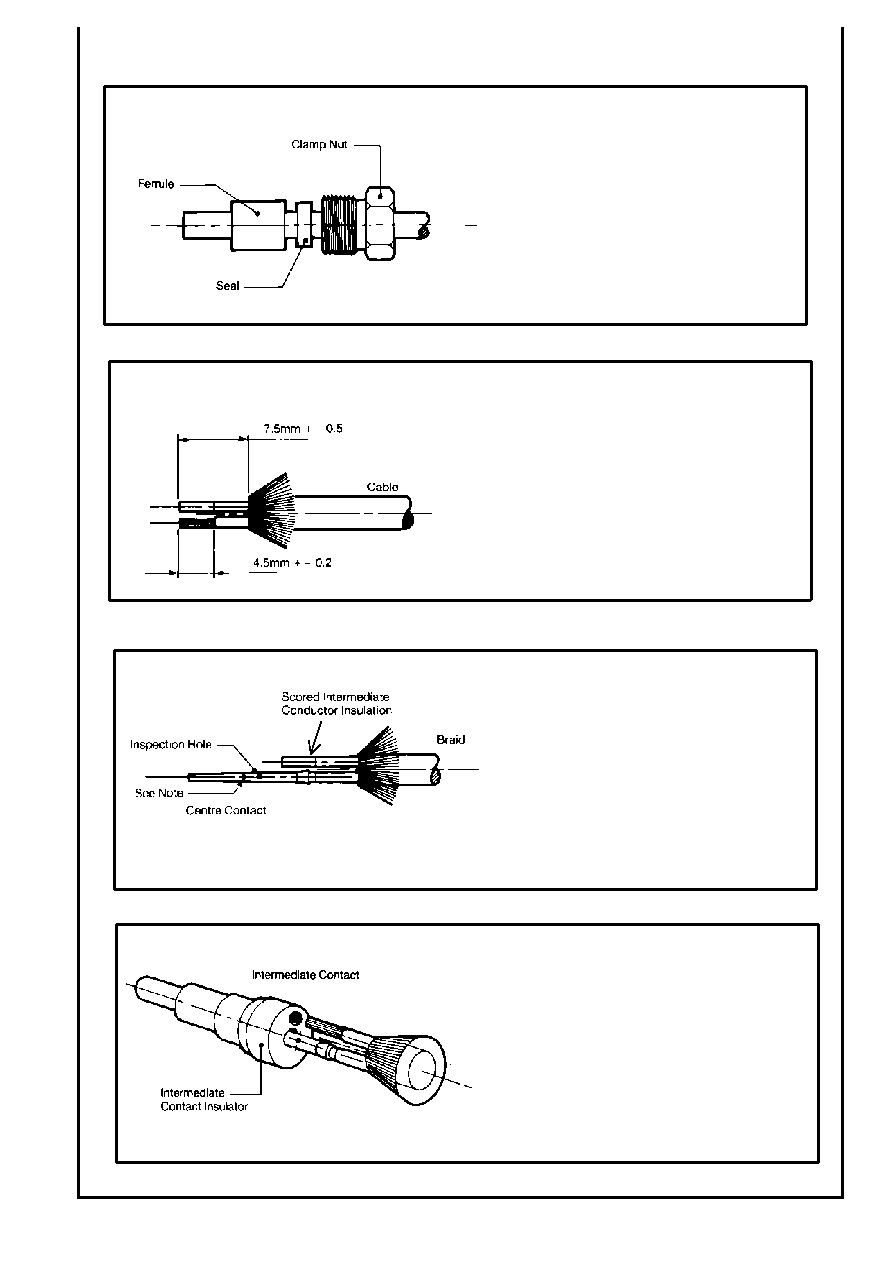

Size #10 Data Bus Contact Assembly Instructions

Slide clamp nut, seal and ferrule over cable.

(Nut & seal only applicable on single way

connector).

Remove outer sheath of cable to 7.5mm comb out all

braids evenly and fold back. Remove cable fillers from

stripped length. Strip the centre contact conductor to

4.5mm. Note: It is recommended that both

intermediate and centre contact conductors are

scored at the correct stripping length. The

intermediate conductor insulation should not be

removed until the centre contact has been crimped.

Crimp centre contact (Pin or Socket) on to the

stripped wire using tool M22520/2-01 and crimp

positioner 294GB-5027-1 (setting No. 4 for 24AWG)

butting rear end of contact to wire insulation. The

conductor end should be visible in the inspection

hole. Note: A second hole is permissible in the

socket contact for manufacturing purposes. It is not

required to be on the same centre line as the

inspection hole.

Strip intermediate contact conductor to 4.5mm.

Insert centre contact into centre hole of intermediate

contact conductor into the outer hole of the

intermediate contact assembly. Push firmly home

until the centre contact is felt to snap into place and

ensure that the insulation of each conductor is fully

inserted into the intermediate contact insulator. The

intermediate conductor should be visible in the

inspection hole in the intermediate contact. There

should be no loose cable strands visible. Crimp the

intermediate contact assembly using the appropriate

cavity of crimp jaw 294GB-5026-1 fitted into

M22520/5-01 tool.

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| 711-17E | FEMALE; MALE, CIRCULAR CONNECTOR, CRIMP, RECEPTACLE |

| 711220 | MALE-FEMALE, RF STRAIGHT ADAPTER |

| 711222 | FEMALE-FEMALE, RF STRAIGHT ADAPTER |

| 711240 | MALE-FEMALE, RF STRAIGHT ADAPTER |

| 711410 | MALE-FEMALE, RF STRAIGHT ADAPTER |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| 711-180A115 | 制造商:TE Connectivity 功能描述: |

| 711-180A26 | 制造商:TE Connectivity 功能描述: |

| 711-180B115 | 制造商:TE Connectivity 功能描述: |

| 711182 | 制造商:Phoenix Contact 功能描述:VDFK 4/K GNYE (VE500) |

| 711-182 | 制造商:WAGO Innovative Connections 功能描述: |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。