- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄368852 > 222233840334 CAPACITOR 330NF 300V PDF資料下載

參數(shù)資料

| 型號: | 222233840334 |

| 英文描述: | CAPACITOR 330NF 300V |

| 中文描述: | 電容330NF 300V |

| 文件頁數(shù): | 16/17頁 |

| 文件大?。?/td> | 562K |

| 代理商: | 222233840334 |

2001 Jun 22

16

BCcomponents

Product specification

Interference suppression film capacitors

MKP 338 6 Y2

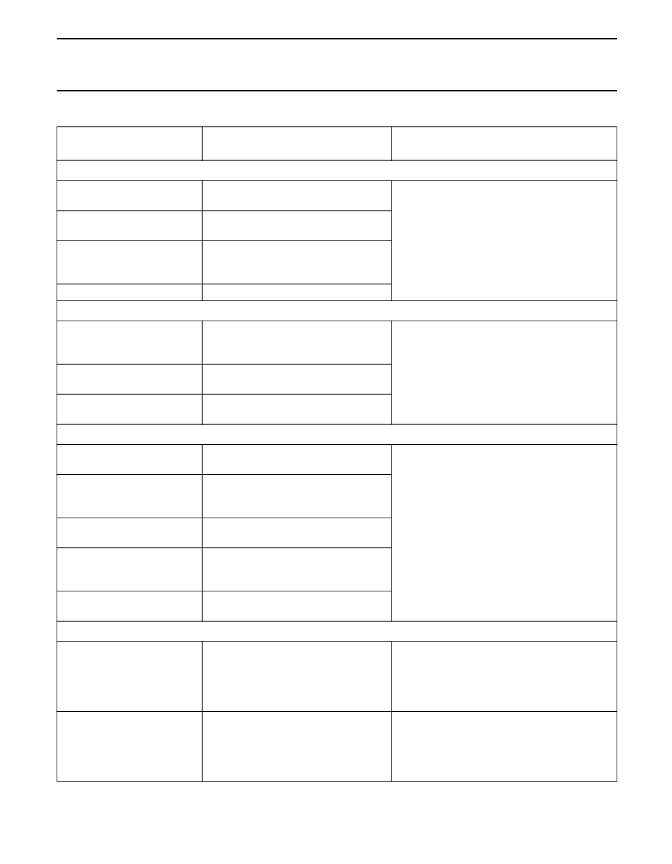

QUICK REFERENCE TEST REQUIREMENTS

TEST

PROCEDURE

(quick reference)

REQUIREMENTS

Robustness of leads

Tensile strength:

“

IEC 60068-2-21

”

Bending:

“

IEC 60068-2-21

”

Resistance to

soldering heat:

“

IEC 60068-2-20

”

Component solvent resistance isopropyl alcohol; 23

°

C; 5 minutes

load 10 N; 10 s

no visible damage

legible marking

|

C/C

| ≤

5%

tan

δ ≤

80

×

10

4

(C

≤

1

μ

F); note 1

tan

δ ≤

50

×

10

4

(C

>

1

μ

F); note 1

load 5 N; 4

×

90

°

solder bath: 260

°

C; 10 s

Robustness of component

Rapid change of temperature:

“

IEC 60068-2-14

”

5 cycles

1 cycle

=

30 minutes at

55

°

C and

30 minutes at 105

°

C

10 to 55 Hz;

amplitude 0.75 mm; 6 hours

half sinewave; 490 m/s

2

; 11 ms

|

C/C

| ≤

5%

tan

δ ≤

80

×

10

4

(C

≤

1

μ

F); note 1

tan

δ ≤

50

×

10

4

(C

>

1

μ

F); note 1

Vibration:

“

IEC 60068-2-6

”

Shock:

“

IEC 60068-2-27

”

Climatic sequence

Dry heat:

“

IEC 60068-2-2

”

Damp heat, cyclic, test Db,

first cycle:

“

IEC 60068-2-30

”

Cold:

“

IEC 60068-2-1

”

Damp heat, cyclic, test Db,

remaining cycles:

“

IEC 60068-2-30

”

Voltage proof:

“

IEC 60384-14

”

16 hours; 105

°

C

|

C/C

| ≤

5%

tan

δ ≤

80

×

10

4

(C

≤

1

μ

F); note 1

tan

δ ≤

50

×

10

4

(C

>

1

μ

F); note 1

R

ins

≥

50% of specified value

2 hours;

55

°

C

V

p

=

2250 V (DC); 1 minute

Other applicable tests

Damp heat, steady state:

“

IEC 60068-2-3

”

56 days; 40

°

C;

90 to 95% RH no load

V

p

=

2250 V (DC); 1 minute

|

C/C

| ≤

5%

tan

δ ≤

80

×

10

4

(C

≤

1

μ

F); note 1

tan

δ ≤

50

×

10

4

(C

>

1

μ

F); note 1

R

ins

≥

50% of specified value

|

C/C

| ≤

10%

Endurance (AC):

“

IEC 60384-14

”

3

×

5 kV pulse voltage

1000 hours; 1.7

×

U

Rac

at 105

°

C;

once per hour; 0.1 s; 1000 V (RMS) via

resistor of 47

;

V

p

=

2250 V (DC); 1 minute

tan

δ ≤

80

×

10

4

(C

≤

1

μ

F); note 1

tan

δ ≤

50

×

10

4

(C

>

1

μ

F); note 1

R

ins

≥

50% of specified value

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| 222233840335 | Power Monitor |

| 222233840473 | CAPACITOR 47NF 300V |

| 222233840474 | CAPACITOR 470NF 300V |

| 222233840475 | Power Monitor |

| 222233840683 | CAPACITOR 68NF 300V |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| 222233840335 | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:CAPACITOR 3.3UF 300V |

| 222233840473 | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:CAPACITOR 47NF 300V |

| 222233840474 | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:CAPACITOR 470NF 300V |

| 222233840475 | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:CAPACITOR 4.7UF 300V |

| 222233840683 | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:CAPACITOR 68NF 300V |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。