- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄382786 > μPD78032Y (NEC Corp.) 8 Bit Single Chip Microcontrollers PDF資料下載

參數(shù)資料

| 型號: | μPD78032Y |

| 廠商: | NEC Corp. |

| 元件分類: | 8位微控制器 |

| 英文描述: | 8 Bit Single Chip Microcontrollers |

| 中文描述: | 8位單片機微控制器 |

| 文件頁數(shù): | 129/339頁 |

| 文件大小: | 1633K |

| 代理商: | ΜPD78032Y |

第1頁第2頁第3頁第4頁第5頁第6頁第7頁第8頁第9頁第10頁第11頁第12頁第13頁第14頁第15頁第16頁第17頁第18頁第19頁第20頁第21頁第22頁第23頁第24頁第25頁第26頁第27頁第28頁第29頁第30頁第31頁第32頁第33頁第34頁第35頁第36頁第37頁第38頁第39頁第40頁第41頁第42頁第43頁第44頁第45頁第46頁第47頁第48頁第49頁第50頁第51頁第52頁第53頁第54頁第55頁第56頁第57頁第58頁第59頁第60頁第61頁第62頁第63頁第64頁第65頁第66頁第67頁第68頁第69頁第70頁第71頁第72頁第73頁第74頁第75頁第76頁第77頁第78頁第79頁第80頁第81頁第82頁第83頁第84頁第85頁第86頁第87頁第88頁第89頁第90頁第91頁第92頁第93頁第94頁第95頁第96頁第97頁第98頁第99頁第100頁第101頁第102頁第103頁第104頁第105頁第106頁第107頁第108頁第109頁第110頁第111頁第112頁第113頁第114頁第115頁第116頁第117頁第118頁第119頁第120頁第121頁第122頁第123頁第124頁第125頁第126頁第127頁第128頁當前第129頁第130頁第131頁第132頁第133頁第134頁第135頁第136頁第137頁第138頁第139頁第140頁第141頁第142頁第143頁第144頁第145頁第146頁第147頁第148頁第149頁第150頁第151頁第152頁第153頁第154頁第155頁第156頁第157頁第158頁第159頁第160頁第161頁第162頁第163頁第164頁第165頁第166頁第167頁第168頁第169頁第170頁第171頁第172頁第173頁第174頁第175頁第176頁第177頁第178頁第179頁第180頁第181頁第182頁第183頁第184頁第185頁第186頁第187頁第188頁第189頁第190頁第191頁第192頁第193頁第194頁第195頁第196頁第197頁第198頁第199頁第200頁第201頁第202頁第203頁第204頁第205頁第206頁第207頁第208頁第209頁第210頁第211頁第212頁第213頁第214頁第215頁第216頁第217頁第218頁第219頁第220頁第221頁第222頁第223頁第224頁第225頁第226頁第227頁第228頁第229頁第230頁第231頁第232頁第233頁第234頁第235頁第236頁第237頁第238頁第239頁第240頁第241頁第242頁第243頁第244頁第245頁第246頁第247頁第248頁第249頁第250頁第251頁第252頁第253頁第254頁第255頁第256頁第257頁第258頁第259頁第260頁第261頁第262頁第263頁第264頁第265頁第266頁第267頁第268頁第269頁第270頁第271頁第272頁第273頁第274頁第275頁第276頁第277頁第278頁第279頁第280頁第281頁第282頁第283頁第284頁第285頁第286頁第287頁第288頁第289頁第290頁第291頁第292頁第293頁第294頁第295頁第296頁第297頁第298頁第299頁第300頁第301頁第302頁第303頁第304頁第305頁第306頁第307頁第308頁第309頁第310頁第311頁第312頁第313頁第314頁第315頁第316頁第317頁第318頁第319頁第320頁第321頁第322頁第323頁第324頁第325頁第326頁第327頁第328頁第329頁第330頁第331頁第332頁第333頁第334頁第335頁第336頁第337頁第338頁第339頁

107

CHAPTER 5 APPLICATIONS OF 16-BIT TIMER/EVENT COUNTER

5.3.2 Remote controller signal reception by PWM output and free running mode (

μ

PD78014, 78014Y, 78018F,

78018FY, 78014H subseries only)

Table 5-2 shows the valid pulse width when a remote controller signal is received by this program. <1> through

<6> below describes how each signal is processed.

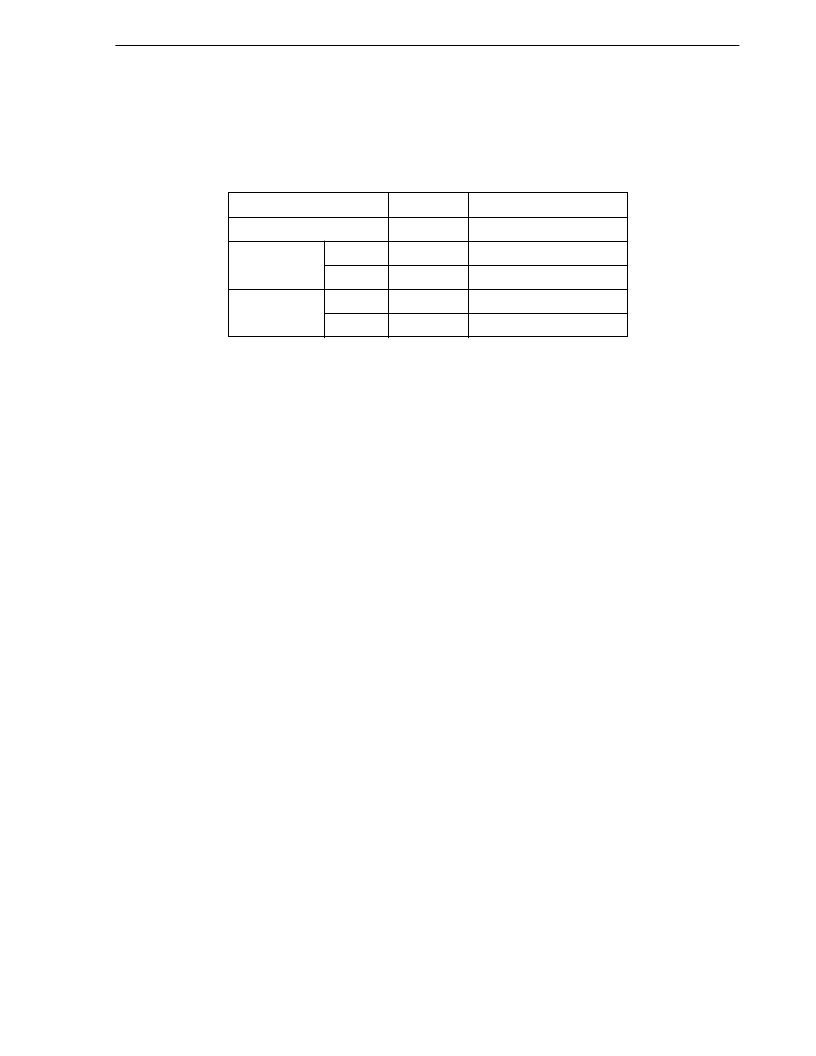

Table 5-2. Valid Time of Input Signal

Signal Name

Output Time

Valid Time

Leader code (low)

9 ms

3 ms-10 ms

Leader code

Normal

4.5 ms

3 ms-5 ms

(high)

Repeat

2.25 ms

1.8 ms-3 ms

Custom/data

0

1.125 ms

0.5 ms-1.8 ms

code

1

2.25 ms

1.8 ms-2.5 ms

<1>

Leader code (low)

The value of the capture register (CR01) is stored to memory by an interrupt request that occurs when

the falling edge of INTP0 is detected.

The pulse width is measured from the difference between the values of CR01 and the compare register

(CR00) when the rising edge is generated.

<2>

Leader code (high)

The pulse width between the high levels of the leader code is measured by the falling-edge interrupt

request INTP0 and the count value of the timer.

<3>

Custom/data code

The pulse width of each 1 bit (1 cycle) is measured by the falling-edge interrupt request INTP0. After

the data of the 32nd bit has been loaded, the system tests if the inverted data and custom code coincide.

It also checks that there is no data of the 33rd bit.

<4>

Repeat code detection

When the high level of the leader code is less than 3 ms, the pulse width from output of the leader code

to the rising edge of the INTP0 is measured.

<5>

Valid period of repeat code

After the valid data has been input, the overflow flag (OVF0) of the 16-bit timer/event counter is tested

by the main program, and the repeat code valid time of 250 ms is measured.

<6>

Time out during pulse width measurement

The OVF0 of the 16-bit timer/event counter is tested during pulse width measurement. If it is detected

two times, time out is assumed and the data is assumed to be invalid.

Because the 16-bit timer/event counter operates in the PWM mode in this example, the remote controller

signal is received and, at the same time, PWM output can be performed by linking the program of

5.2

PWM Output.

相關PDF資料 |

PDF描述 |

|---|---|

| μPD78012B(A) | 8 Bit Single Chip Microcontrollers |

| μPD78012BY | 8 Bit Single Chip Microcontrollers |

| μPD78012H | 8 Bit Single Chip Microcontrollers |

| μPD78012H(A) | 8 Bit Single Chip Microcontrollers |

| μPD78013 | 8 Bit Single Chip Microcontrollers |

相關代理商/技術參數(shù) |

參數(shù)描述 |

|---|---|

| PD780336GC-XXX-9EV | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:Microcontroller |

| PD7-80-70A | 制造商:MERRIMAC 制造商全稱:MERRIMAC 功能描述:0 , 75 ohm POWER DIVIDERS / COMBINERS |

| PD784054GCA2 | 制造商:NEC 制造商全稱:NEC 功能描述:16-BIT SINGLE-CHIP MICROCONTROLLER |

| PD784976A | 制造商:NEC 制造商全稱:NEC 功能描述:16-Bit Single-Chip Microcontroller |

| PD7869 | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:Optoelectronic |

發(fā)布緊急采購,3分鐘左右您將得到回復。